Sustainable heating and heat preservation liquid sulfur tank container

A liquid sulfur tank type, heating and heat preservation technology, applied in the directions of tank trucks, packaging, transportation and packaging, can solve the problems of large heat loss, environmental pollution, and high heating costs, to prevent excessive temperature, prevent environmental pollution, and avoid excessive heat. fast corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

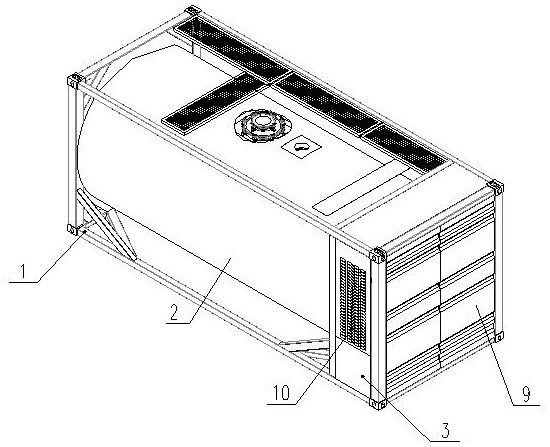

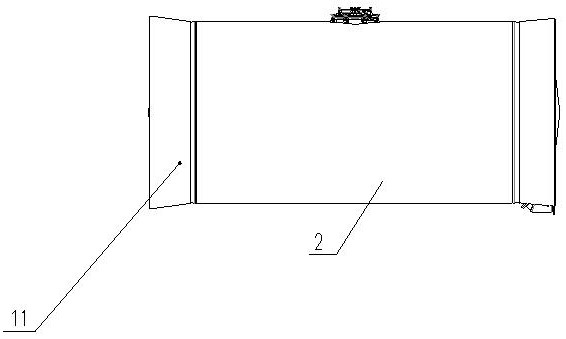

[0039] Embodiment 1, please refer to the attached Figure 1-7 , a sustainable heating and heat preservation liquid sulfur tank container, including a box frame 1, a tank body 2 and a control warehouse 3 are arranged inside the box body frame 1, and the bottom of the tank body 2 and the bottom of the box body frame 1 are skirts The connecting structure 11 of the skirt seat is fixed by bolts. The strength of the skirt connecting structure 11 is reliable and the force is reasonable. Extending the skirt connecting plate to the vicinity of the straight edge of the head can avoid the transition area where the stress of the head itself is relatively large. , to effectively reduce the stress concentration at the junction of the connecting plate and the head. The material of the connecting plate is Q355D steel plate. There are several heating sleeves 12 inside the tank body 2 near the lower end. The heating sleeves 12 are made of high-temperature-resistant and corrosion-resistant metal....

Embodiment 2

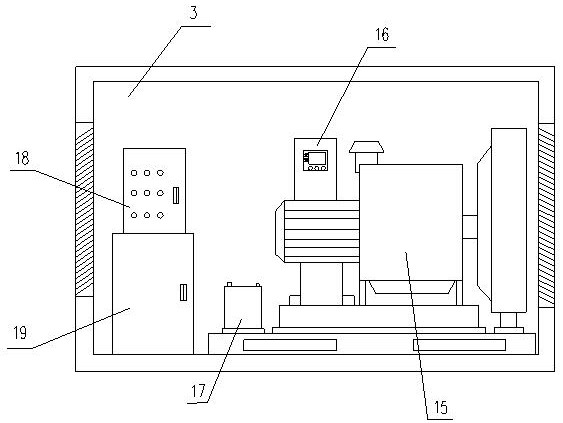

[0045] Embodiment 2, please refer to the attached figure 1 and 2 , the temperature controller 19a is provided with an outer protective shell, the automatic controller 18 includes a control box shell, the bottom of the control box shell and the top of the outer protective shell are fixed by bolts, and the generator set 15 is located at the temperature controller One side of 19a is bolted to the inner bottom of the box frame 1 through the base, and the box frame 1 is located on the side wall at one end of the control cabin 3 and is provided with a door 9, which can be opened to the automatic controller 18, power generation The unit 15 and the temperature controller 19a perform inspection and maintenance operations. Two heat dissipation fences 10 are symmetrically arranged on both sides of the control cabin 3, and each of the heat dissipation fences 10 is embedded on the liquid sulfur container shell, and the power generation The air outlet of the heat dissipation water tank of ...

Embodiment 3

[0046] Embodiment three, please refer to the attached Figure 8 and 9 , the top center of the tank body 2 is provided with an injection port 6, and the injection port 6 is provided with a conventional flip-type sealed hatch, which can not only facilitate the injection of liquid sulfur, but also enable personnel to enter the interior of the tank body when the tank is empty , and one side of the injection port 6 is provided with a breathing safety valve 8, and two breathing safety valves 8 may also be provided, both of which are located at the top of the cylinder. The seat pressure is 0.113MPa, and the negative pressure is 0.021MPa, which can meet the safety discharge requirements of the tank body 2. The bottom of the tank body 2 away from the control chamber 3 is connected with a discharge valve 4, and the discharge valve 4 is A ball valve with a heat-conducting oil structure, the discharge valve 4 is electrically connected to the output end of the generator set 15 through wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com