Liquid Discharge Apparatus, Liquid Discharge Method and Non Transitory Computer-Readable Medium

A liquid discharge and equipment technology, applied in printing, printing devices, inking devices, etc., can solve the problem of no ink circulation, etc., achieve the effect of reducing power consumption and heat generation, and suppressing the deterioration of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0037]

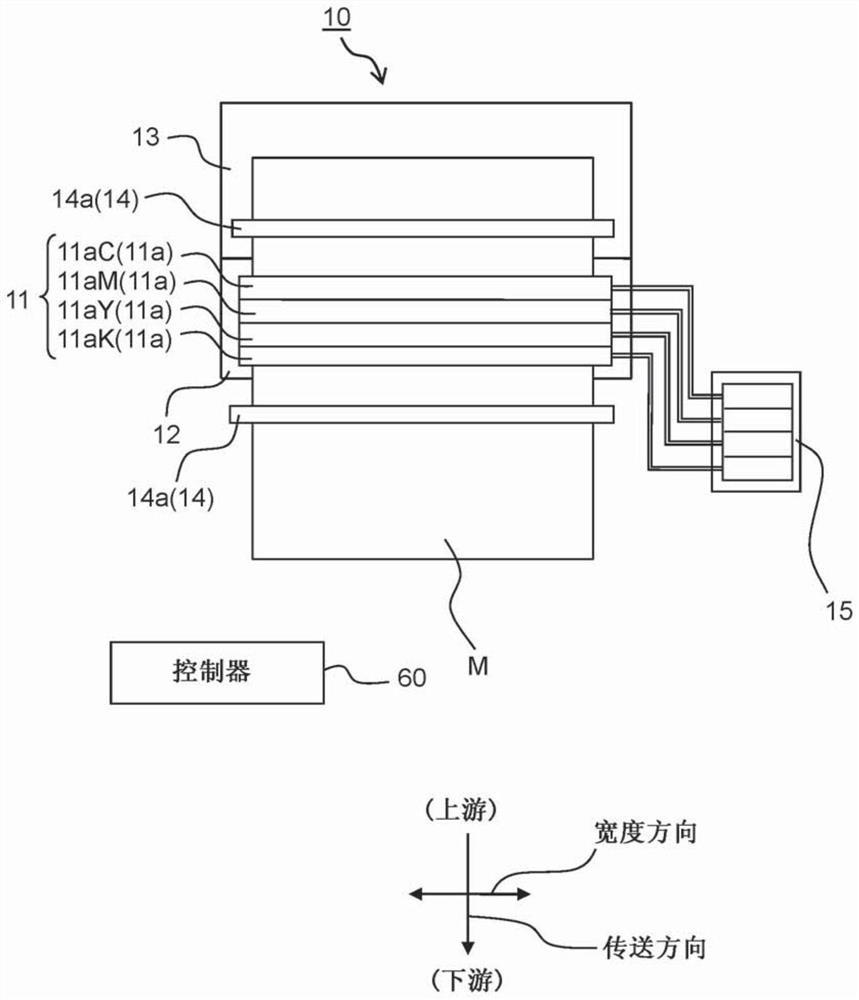

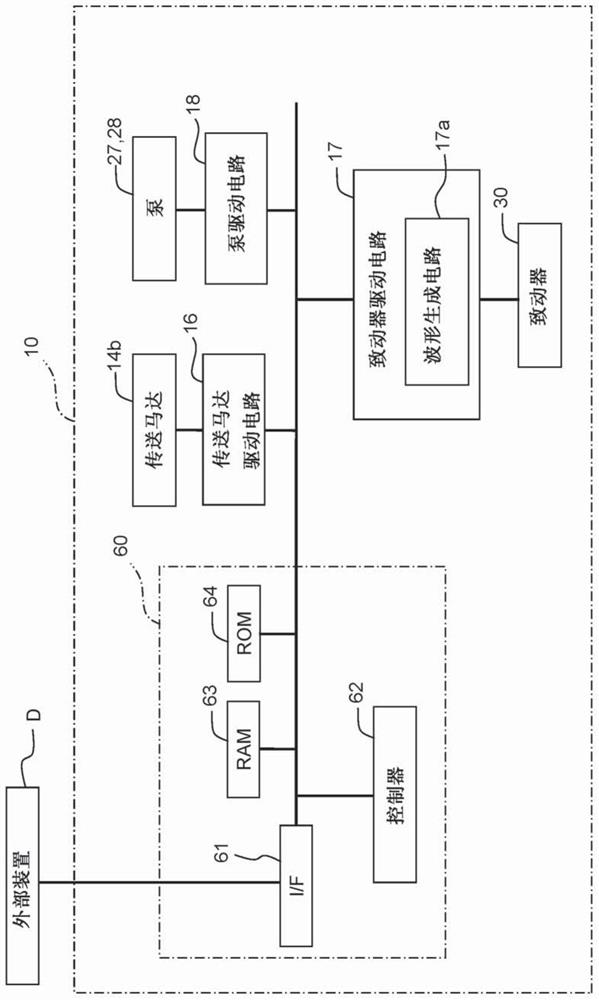

[0038] As the liquid discharge apparatus 10 according to the first embodiment (see figure 1 and figure 2 ), an inkjet printer that performs printing on a recording medium M by discharging ink is explained below. The liquid discharge device 10 is not limited to an inkjet printer that discharges ink as liquid. The liquid discharge device 10 may be a liquid discharge device that discharges any liquid other than ink.

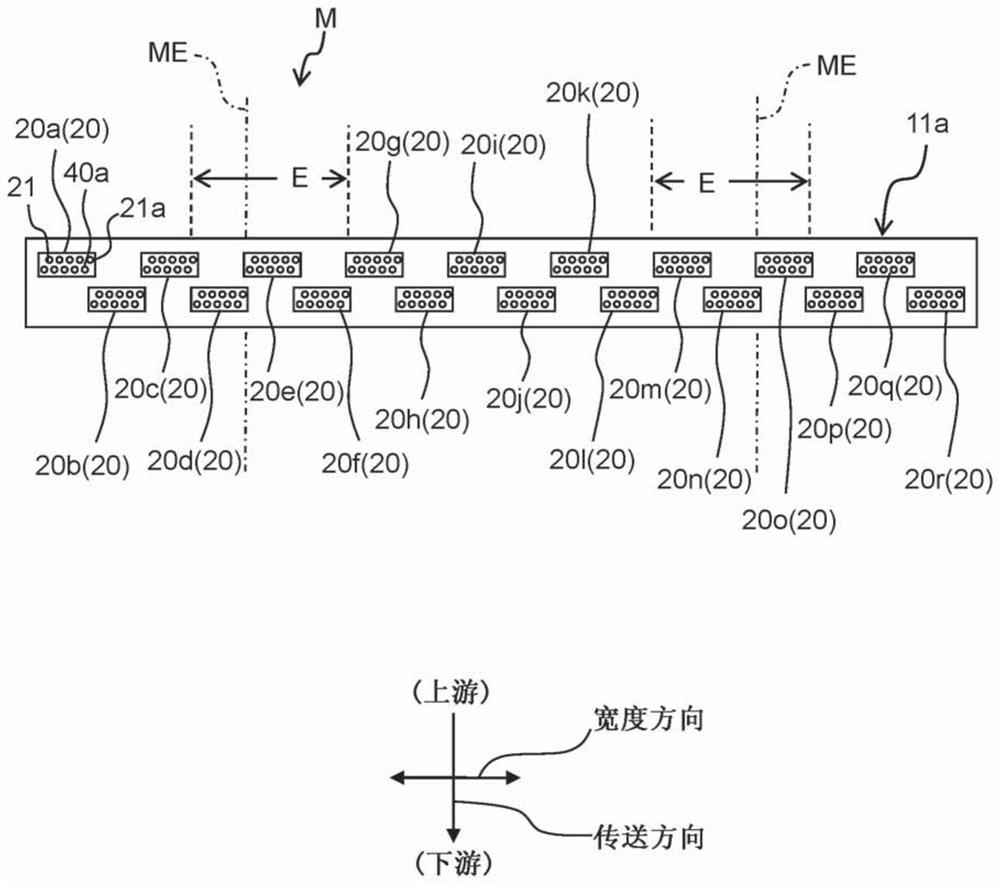

[0039] The liquid discharge apparatus 10 of the line head system is employed in the first embodiment. The liquid discharge apparatus 10 includes a head unit 11 , a platen 12 , a tray 13 , a conveyor 14 , a storage tank 15 and a controller 60 . The head unit 11 includes one or more (for example, four) discharge heads 11a. The discharge head 11a is longer than the recording medium M in the width direction.

[0040] Each discharge head 11a includes a passage forming body and a volume changing portion. The inside of the channel-forming body is provided...

no. 2 example

[0141] Such as Figure 12 As depicted in , the liquid discharge device 10 according to the second embodiment includes a temperature sensor 70 that detects the temperature in the liquid discharge device 10 . Any other configuration than the temperature sensor 70 is similar to that in the first embodiment, and thus an explanation thereof is omitted.

[0142] The temperature sensor 70 is a sensor that detects the temperature of air in contact with the meniscus of ink formed in the nozzle hole 21 a of the head chip 20 . For example, the temperature sensor 70 is provided in the discharge head 11 a in the liquid discharge apparatus 10 . The temperature sensor 70 detects the temperature around the discharge head 11 a , which is the temperature in the liquid discharge apparatus 10 . The detected temperature may be corrected based on a predetermined correspondence between the detected temperature and the temperature in the vicinity of the nozzle hole 21a.

[0143] When the detection...

no. 3 example

[0151] Such as Figure 12 As depicted in , the liquid discharge device 10 according to the third embodiment includes a humidity sensor 80 that detects humidity in the liquid discharge device 10 . Any other configuration than the humidity sensor 80 is similar to that in the first embodiment, and thus an explanation thereof is omitted.

[0152] The humidity sensor 80 is a sensor that detects the humidity of air in contact with the meniscus of ink formed in the nozzle hole 21 a of the head chip 20 . For example, the humidity sensor 80 is provided in the discharge head 11 a in the liquid discharge apparatus 10 . The humidity sensor 80 detects the humidity around the discharge head 11 a , which is the humidity in the liquid discharge apparatus 10 . The detected humidity may be corrected based on a predetermined correspondence between the detected humidity and the humidity in the vicinity of the nozzle hole 21a.

[0153] When the detected humidity detected by the humidity sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com