Automatic torsion type oil pipe coating device

A coating device and oil pipe technology, which can be applied to cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of larger pipe diameter at the bend of the oil pipe, cumbersome manual winding process, and large amount of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

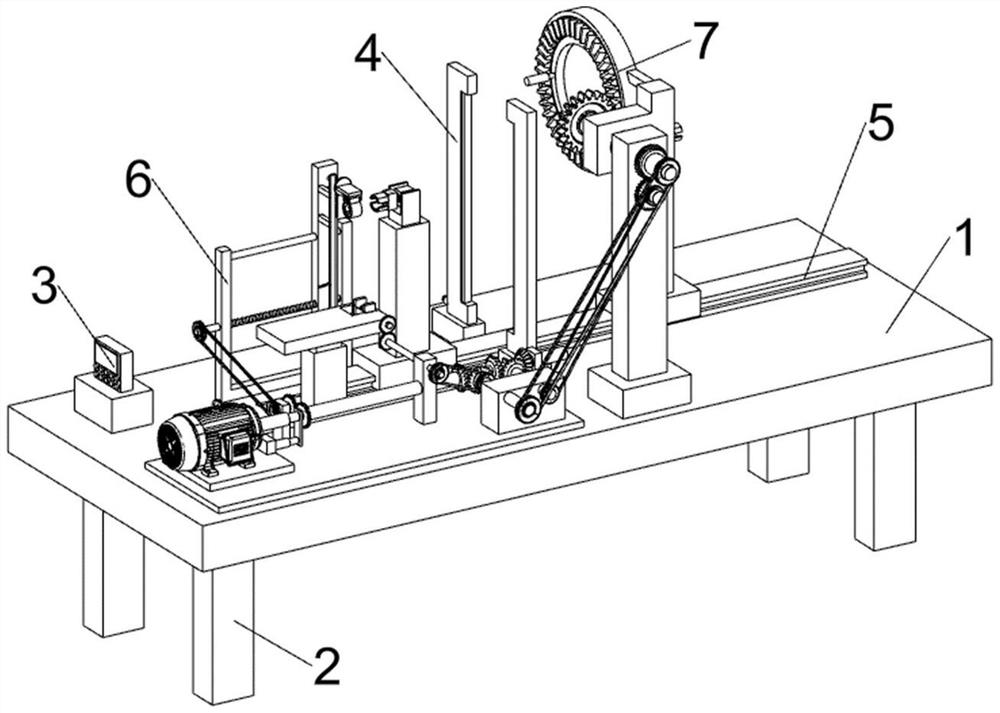

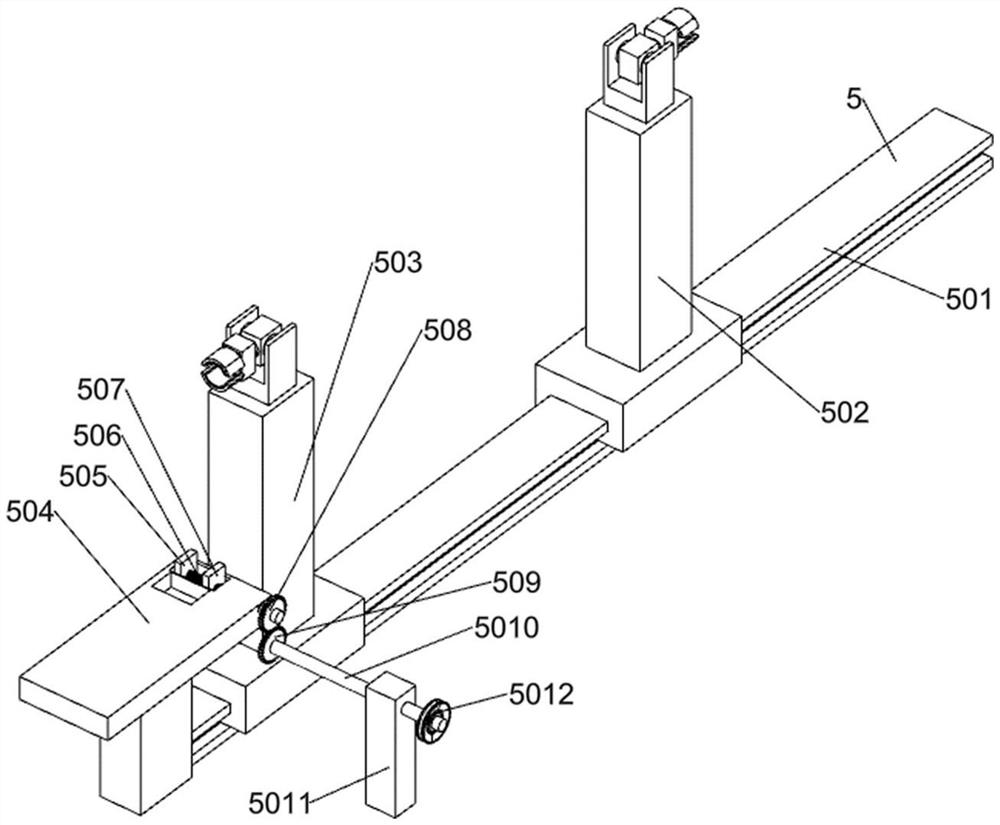

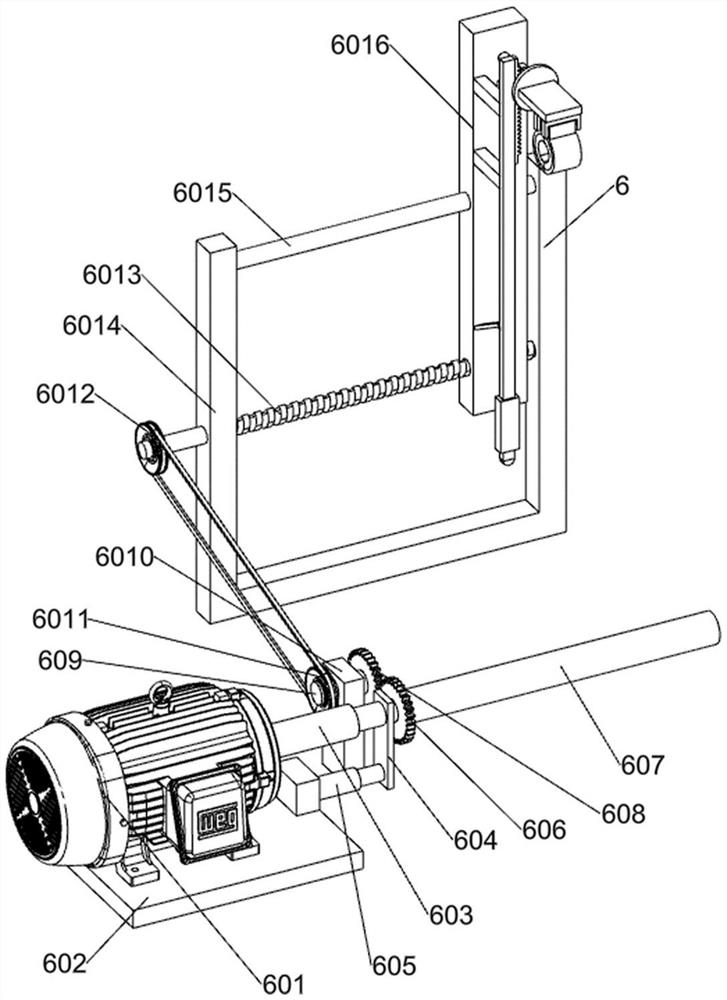

[0028] An automatic twisting oil pipe coating device, such as Figure 1-7 As shown, it includes a working machine board 1, a supporting foot 2, an operation control panel 3, a laser scanning detection door 4, a fixed alignment mechanism 5, a surface treatment mechanism 6, and a covering mechanism 7; the lower part of the working machine board 1 and the supporting bottom The feet 2 are welded; the operation control panel 3 is arranged above the working machine board 1; the upper part of the working machine board 1 is connected with the laser scanning detection door 4; It is connected with the surface treatment mechanism 6; the upper part of the machine tool plate 1 is connected with the coating mechanism 7; the coating mechanism 7 is connected with the surface treatment mechanism 6; the surface treatment mechanism 6 is connected with the fixed normal position mechanism 5; the fixed normal position mechanism 5 is connected with covering mechanism 7.

[0029] When using the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com