Powder slurry stirring equipment for gypsum production

A mixing equipment and slurry technology, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems that the gypsum powder slurry cannot be stirred evenly and affect the quality of the finished gypsum product, and achieve good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

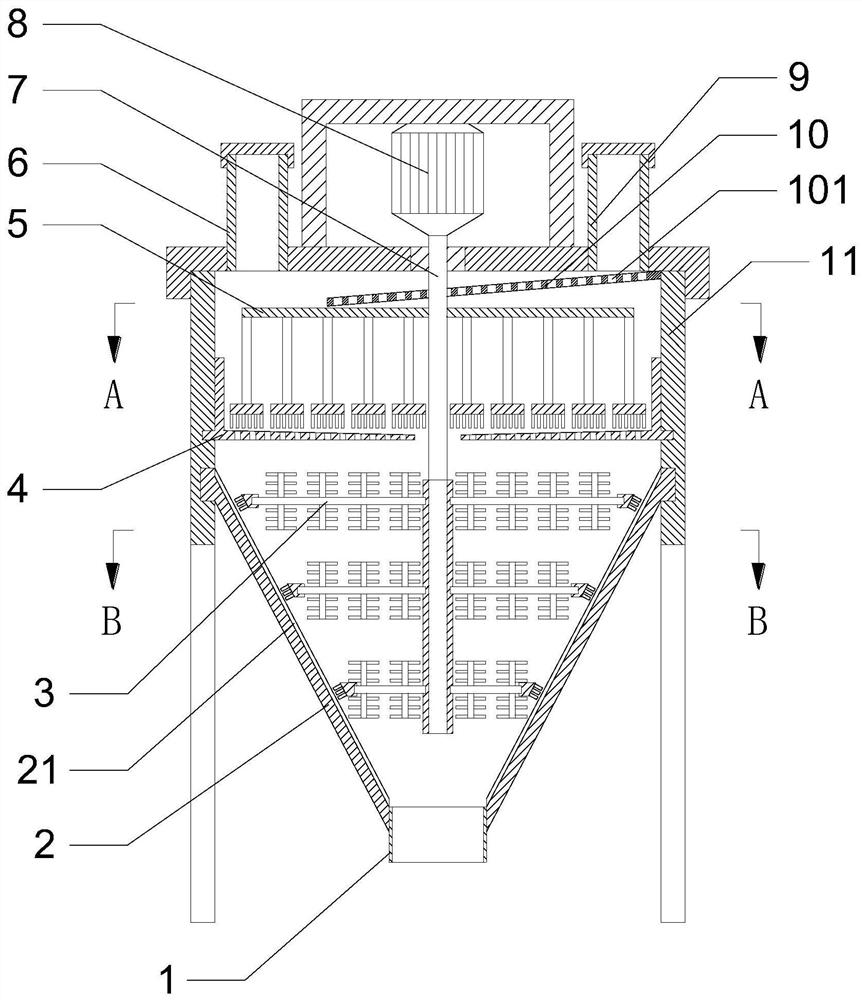

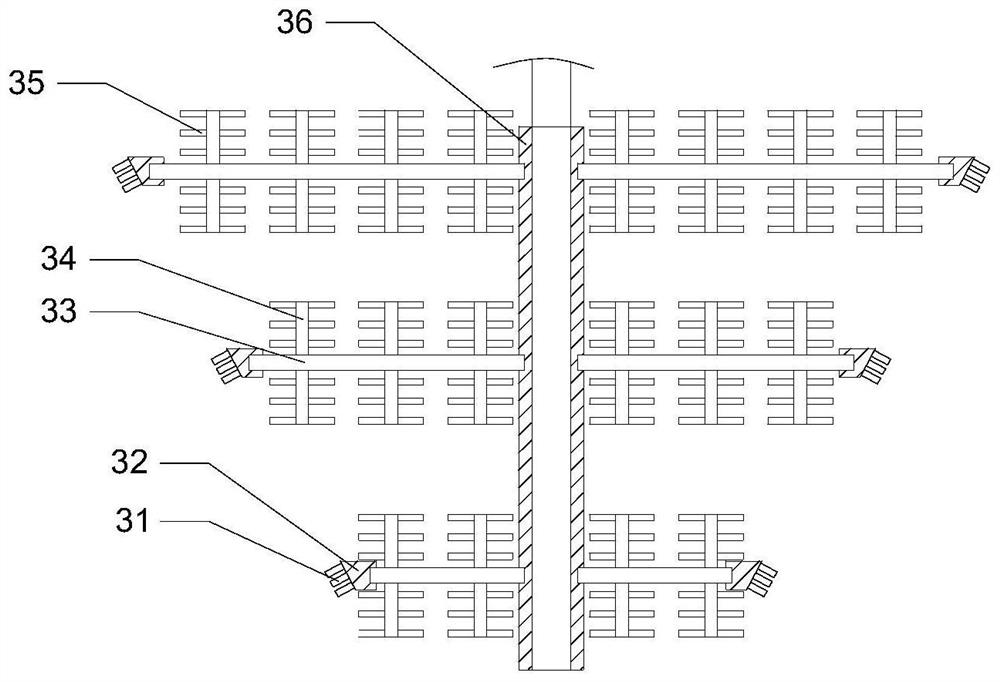

[0029] Such as Figure 1-6 Shown, a kind of powder slurry mixing equipment for gypsum production comprises a mixing box 11, the top surface of the mixing box 11 is provided with a feed pipe 6 and a water inlet pipe 9, and a rotating motor 8 is installed on the top surface of the mixing box 11, and the rotating motor 8 is connected with a rotating shaft 7 extending into the stirring box 11, and the rotating shaft 7 is sequentially installed with a primary stirring mechanism 5 and a secondary stirring mechanism 3 from top to bottom, and the primary stirring mechanism 5 includes a plurality of stirring plates installed on the rotating shaft 7 54, the bottom surface of the stirring plate 54 is equipped with a plurality of vertical rods 53 along its length direction, the lower end of the vertical rods 53 is equipped with a vertical stirring assembly, and the inner wall of the stirring box 11 is detachably installed with a guide located below the stirring assembly. The disc 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com