Biological filtration waste gas removal equipment

A biological filtration and waste gas technology, applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reduced waste gas filtration effect, thinner filter screen thickness, toxic and harmful gases, etc. The effect of reducing corrosion and reducing endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

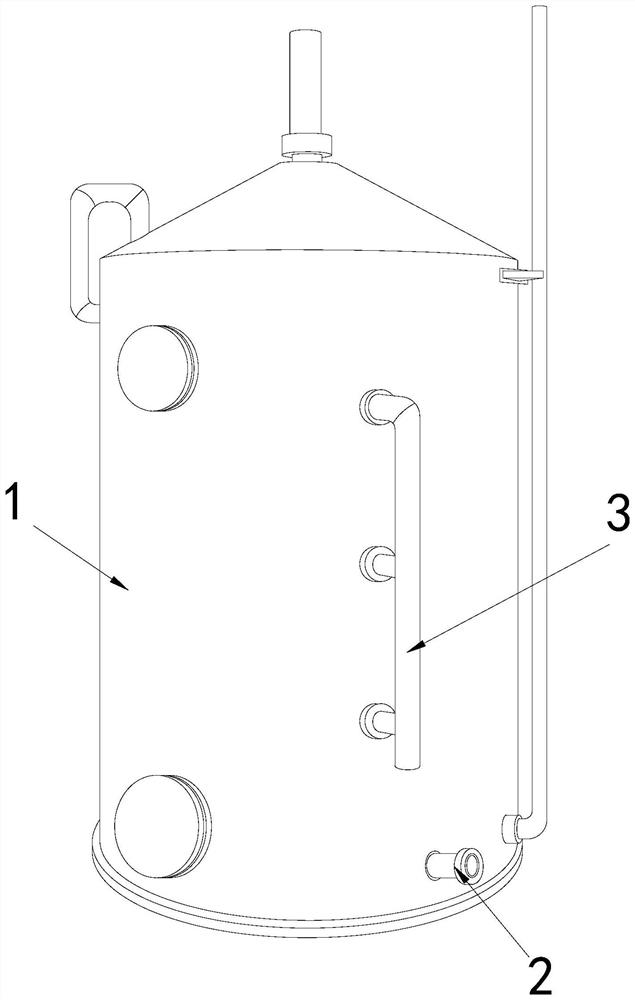

[0028] The present invention provides a kind of biological filtration waste gas removal equipment, its structure includes a tower body 1, a discharge pipe 2, and an air intake pipe 3, the discharge pipe 2 is horizontally welded at the bottom end of the front of the tower body 1, and the air intake pipe 3 is installed on The front of the tower body 1 is on the right side.

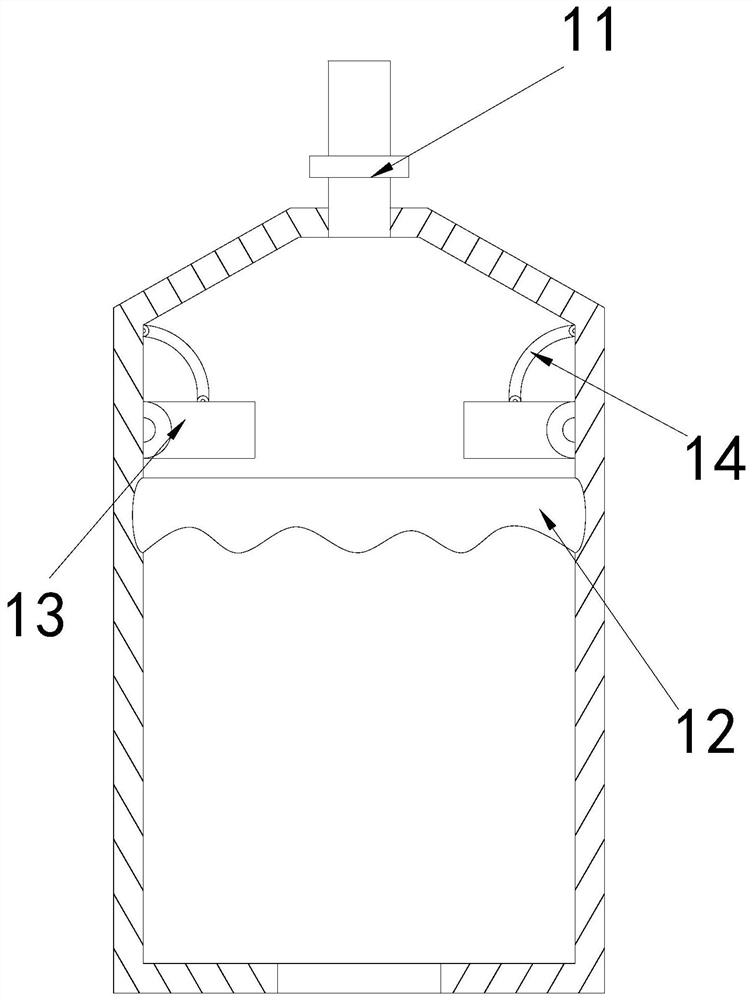

[0029] The tower body 1 is provided with an exhaust pipe 11, a filter screen 12, a push mechanism 13, and a push bar 14. The exhaust pipe 11 runs through the center of the top of the tower body 1, and the filter screen 12 is set in the inner wall of the tower body 1. In the upper position, the pushing mechanism 13 is installed on the inner wall of the tower body 1 and above the filter screen 12 , and the push bar 14 is installed between the top of the pushing mechanism 13 and the inner wall of the tower body 1 .

[0030] Wherein, the pushing mechani...

Embodiment 2

[0036] as attached Figure 6 to attach Figure 7 Shown:

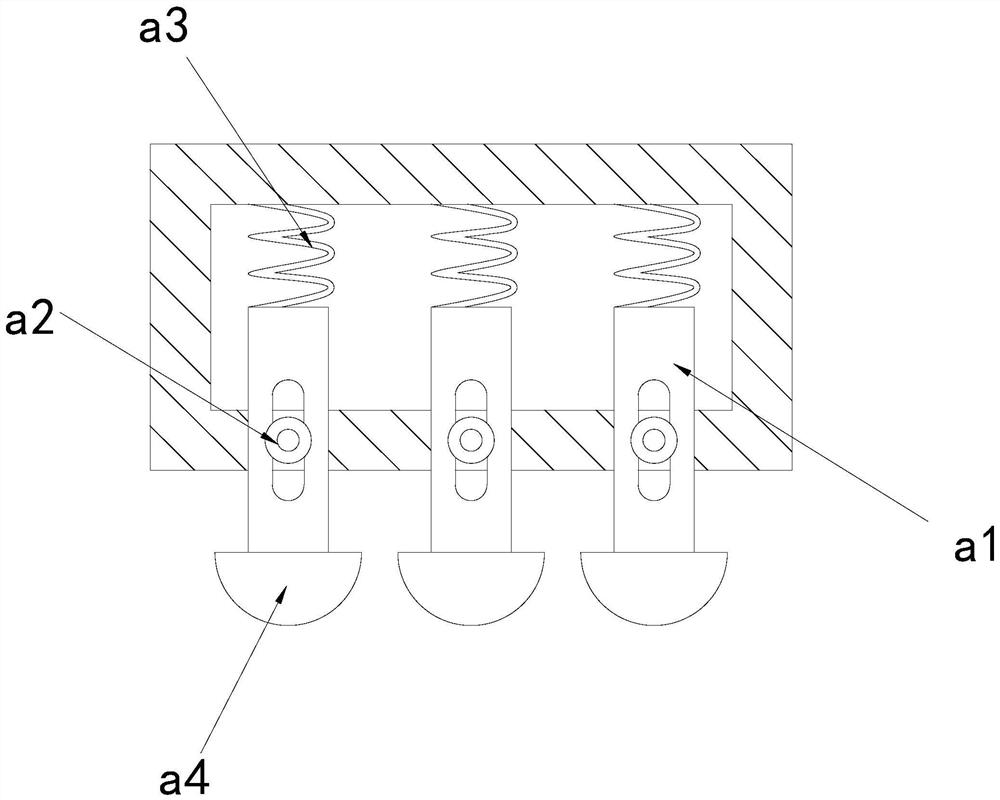

[0037] Wherein, the clamping block s3 is provided with a support block e1, a slot e2, a push rod e3, and an elastic bar e4, the slot e2 is located inside the two sides of the support block e1, and the push rod e3 passes through the bottom of the slot e2 Cooperating with the elastic strip e4, the side of the push rod e3 is arc-shaped, which is beneficial to fully cooperate with the inner side of the swing plate s2.

[0038] Wherein, the push rod e3 is provided with a support frame r1, a swing rod r2, a reset bar r3, and a scraper r4, the swing rod r2 is installed on the left side of the support frame r1, and the reset bar r3 is clamped on the left end of the swing rod r2 Between the bottom surface and the inner wall on the right side of the support frame r1, the scraper r4 is fixed on the right end of the swing rod r2, and the reset bar r3 is made of rubber material with elasticity, which is beneficial to drive the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com