Aquatic product pickling material and preparation method of instant aquatic product

A technology of aquatic products and marinade, which is applied in food science and other fields, can solve the problems of human health hazards and much less oil consumption, and achieve the effect of ensuring health, soft texture and delicious taste, and enriching product types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

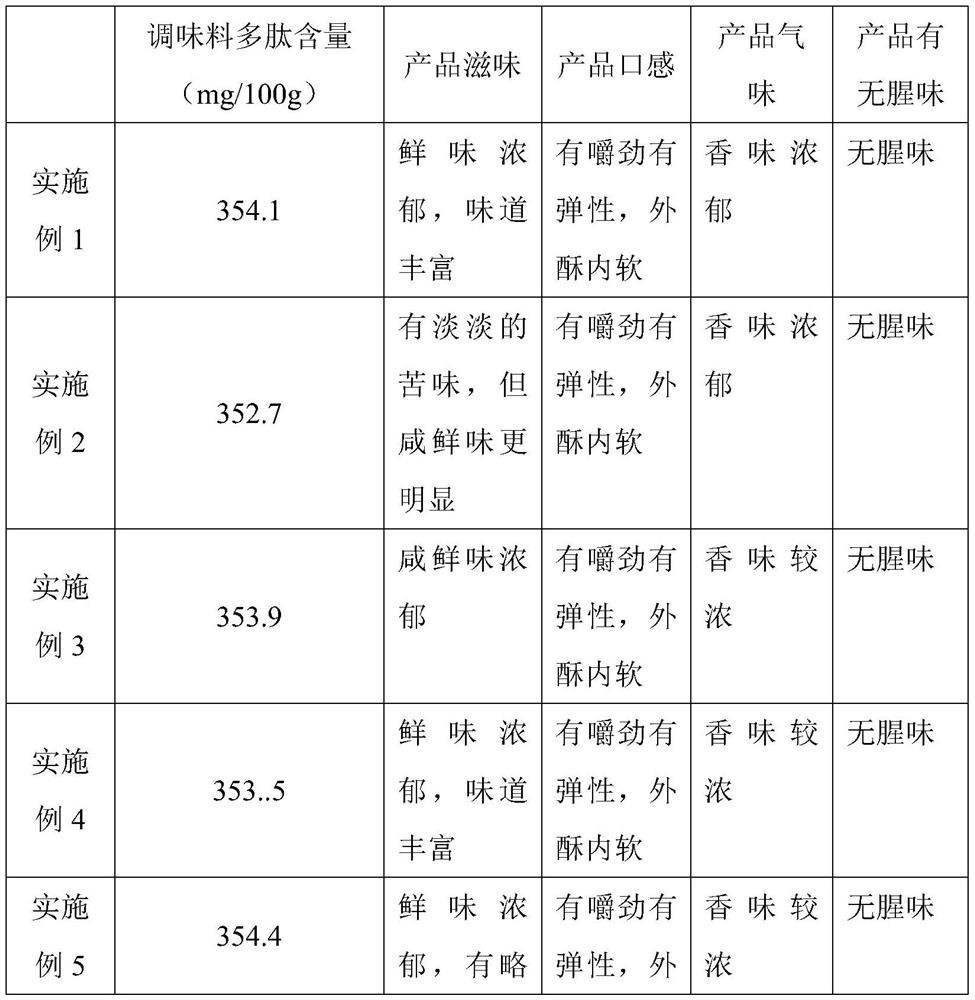

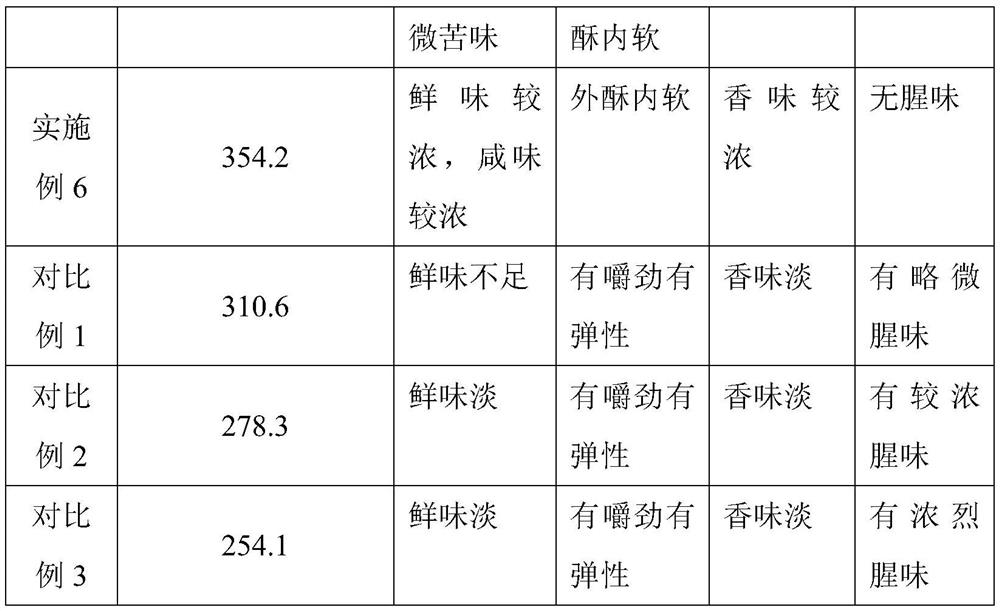

Examples

Embodiment 1

[0040] 1. Thaw the frozen dried large yellow croaker in running water until the carcass becomes soft, cut off the fish meat along the fish bone and cut into pieces, add water to grind and homogenate, and obtain a homogenate with a mass ratio of material to liquid of 1:2;

[0041] 2. Put the homogenate in a pot, boil it at 100°C for 0.8h, pass it through a 70-mesh sieve, collect the filtrate and filter residue respectively, add flavor protease with 0.6% of the residue quality to the filter residue for further enzymolysis, and heat at 50°C After 4 hours of enzymatic hydrolysis under the same conditions, inactivate the enzyme in a water bath at 100°C for 14 minutes, mix the enzymolyzed solution obtained by filtering after the inactivation with the collected filtrate, and centrifuge at a speed of 8000r / min and a temperature of 3°C for 10min, and then Concentrating to obtain dried large yellow croaker concentrated freshness-enhancing liquid;

[0042] 3. Prepare the freshness-enhanc...

Embodiment 2

[0048] 1. Thaw the frozen dried large yellow croaker in running water until the carcass becomes soft, cut off the fish meat along the fish bone and cut into pieces, add water to grind and homogenate, and obtain a homogenate with a mass ratio of material to liquid of 1:3;

[0049]2. Put the homogenate in a pot, boil it at 100°C for 1.2 hours, pass it through an 80-mesh sieve, collect the filtrate and filter residue respectively, add papain with 0.4% of the residue quality to the filter residue for further enzymatic hydrolysis, and heat at 60°C After enzymatic hydrolysis for 5 hours under conditions, inactivate the enzyme in a water bath at 100°C for 16 minutes, mix the enzymolyzate obtained by filtering the enzymatic hydrolysis with the collected filtrate, and centrifuge for 20 minutes at a speed of 10,000r / min and a temperature of 4°C, and then Concentrating to obtain dried large yellow croaker concentrated freshness-enhancing liquid;

[0050] 3. Prepare the freshness-enhancin...

Embodiment 3

[0056] 1. Thaw the frozen dried large yellow croaker in running water until the carcass becomes soft, cut off the fish meat along the fish bone and cut into pieces, add water to grind and homogenate, and obtain a homogenate with a mass ratio of material to liquid of 1:4 ;

[0057] 2. Add flavor protease with 0.5% mass of the homogenate for further enzymolysis. After enzymolysis at 55°C for 6 hours, inactivate the enzyme in a water bath at 100°C for 15 minutes, put the solution after inactivation at a speed of 9000r / min, temperature Under the condition of 5°C, centrifuge for 15 minutes, and then concentrate to obtain the dried large yellow croaker concentrated and fresh liquid;

[0058] 3. Prepare fresh-enhancing marinade according to the following parts by weight: 80 parts of dried large yellow croaker concentrated fresh-enhancing liquid, 2 parts of ginger powder, 6 parts of cooking wine, 4 parts of glucose, 1 part of table salt, and 1 part of Chinese prickly ash, mix well and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com