Construction method of carbon fiber composite core wire

A construction method and carbon fiber technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of shrinkage of carbon fiber composite mandrel, damage of outer aluminum strands, relaxation of aluminum strands of conductors, etc., to reduce damage, ensure project quality, and solve problems. The effect of overhead line dropping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a construction method for a carbon fiber composite core conductor, comprising the following steps:

[0036] S1: Conductor tension pay-off: Tension pay-off is in a selected pay-off area, according to the length of the wire and the length of the tension section, the wire reel is dispersed and transported to the location selected for the wiring, and the tension machine, Traction machine, under the condition that the tension machine applies a certain tension, the traction machine spreads the wires through the traction rope. According to the number of wires in each item, it can be divided into one pull one, one pull two, one pull four, one pull There are six methods of traction; divided into: a, traction field, tension field machinery and equipment entering the field; b, unfolding the traction rope; c, unfolding the traction rope; d, under the action of stretching equipment, through the traction rope Tension pay-off;

[0037] S2: wire tightening: te...

Embodiment 2

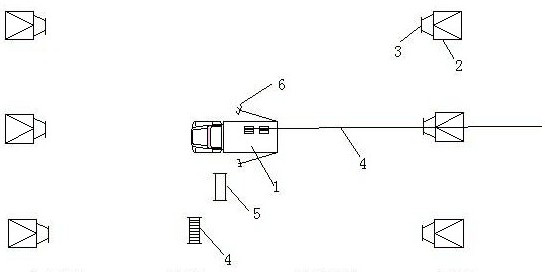

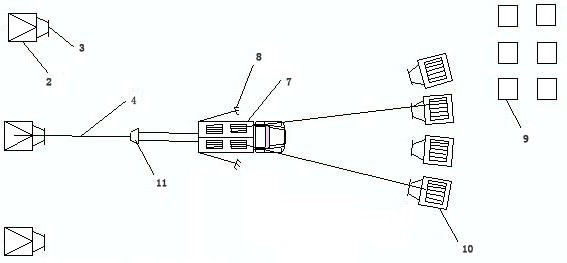

[0049] This embodiment provides the layout of the traction field in Embodiment 1 (such as figure 1 ) and the arrangement of the tension field (such as figure 2 ).

[0050] Towing Field Operation Procedures:

[0051] 1. Wind the traction rope around the traction wheel as required.

[0052] 2. Start the traction machine and slowly retract the traction rope to release the anchor.

[0053] 3. When changing discs, the tail of the traction rope should be anchored first, and then the anti-bending connector should be released.

[0054] 4. Use a crane to lower the traction rope reel, replace it with an empty reel, and fix it.

[0055] 5. The traction is ready, and the traction is commanded by the tension field, otherwise the traction is not allowed.

[0056] 6. When the wire is pulled to the traction field, it should be anchored in time.

[0057] 7. When the wire is finished, if it is necessary to turn around, a certain distance should be left after the turn to facilitate the op...

Embodiment 3

[0085] This application provides a construction method for carbon fiber composite core conductors, which is an improvement on the basis of Example 2: the sequence of tightening the wires in step S2 is: first the middle phase, then the second phase; the length of the incoming wire matches the length of the unwinding wire. Tighten the whole line in the same direction, slowly tighten the sub-conductor, and when the anchorage wire at the operation end is not stressed, stop the traction, and remove the anchorage at the wire end from the wire. Continue to tighten the sub-conductor, pay attention to tighten the sub-conductor symmetrically, and keep the force balance of the pay-off block. After the sag adjustment of each gear meets the requirements, stop traction. Restore the line end of the operation end to the anchor, tighten the lever block, loosen the twisted rope, and remove the tools of the traction system. Use the hand lever hoist near the anchor to fine-tune the sag of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com