Composite lithium metal negative electrode and preparation method thereof

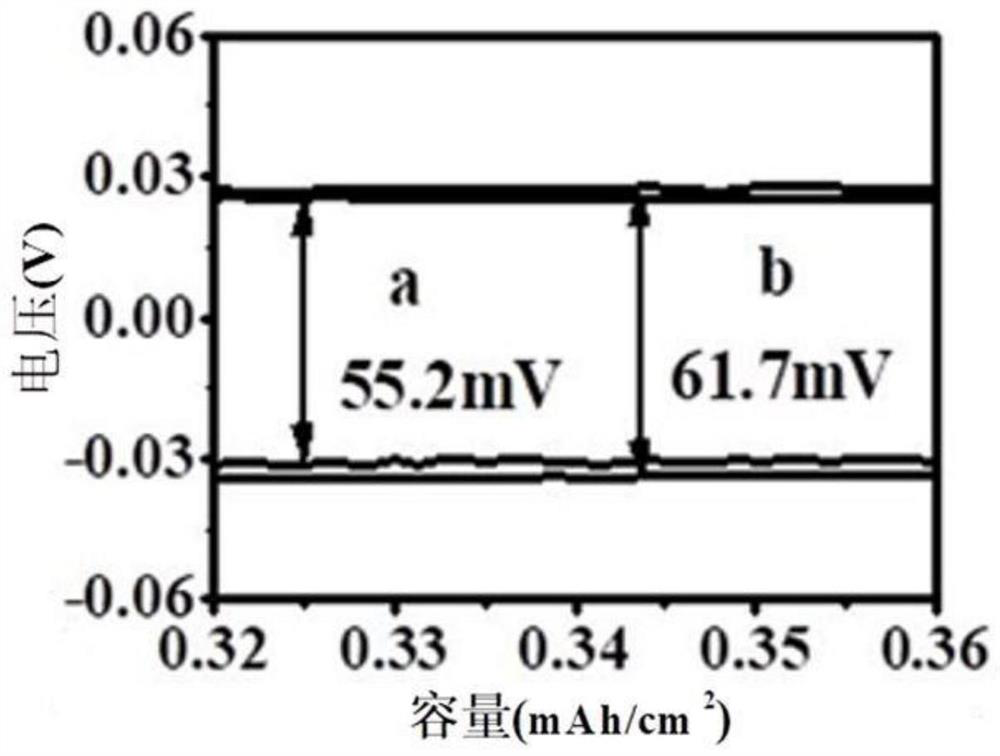

A metal negative electrode and composite lithium technology, applied in negative electrodes, battery electrodes, lithium batteries, etc., can solve the problems of affecting the service life of lithium metal batteries, difficult Li uniform deposition, high nucleation overpotential, etc., to reduce lithium nucleation Effects of overpotential, increased cycle stability, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Put 100mg of graphene oxide and 100mg of 1-butyl-3-methylimidazolium chloride (BMIMCl) into a 25mL round-bottomed flask, stir well, and ultrasonicate at room temperature for 1h; then add 20mg of silver nitrate to it, Continue to sonicate for 0.5h to obtain a brown mixture;

[0031] (2) Add 0.2 g of sodium citrate to the mixture obtained in step (1), stir evenly, transfer it to a 25 mL polytetrafluoroethylene reactor, and place it in a thermostat at 180° C. for 20 hours to obtain a gel-state mixture . After washing the gel-state mixture with deionized water, place it in a freeze dryer for 48 hours to obtain a metal heterogeneous particle / reduced graphene oxide composite material;

[0032](3) Cut single-layer nickel foam with a direct slicer, a 10mm diameter disc, take a piece and put it into the mold; it is also called the foam that 1.5mg of metal heterogeneous particles / reduced graphene oxide composite material is evenly sprinkled in the mold On nickel, a lithium-...

Embodiment 2

[0036] (1) 100mg graphene oxide and 100mg 1-butyl-3-methylimidazolium bisulfate (BMIMHSO 4 ) into a 25mL round-bottomed flask, stirred evenly, and ultrasonicated at room temperature for 1 hour; then added 100 mg of silver nitrate to it, and continued ultrasonication for 0.5 hour to obtain a brown mixture;

[0037] (2) Add 0.2 g of sodium citrate to the mixture obtained in step (1), stir evenly, transfer it to a 25 mL polytetrafluoroethylene reactor, and place it in a thermostat at 180° C. for 20 hours to obtain a gel-state mixture . After washing the gel-state mixture with deionized water, place it in a freeze dryer for 48 hours to obtain a metal heterogeneous particle / reduced graphene oxide composite material;

[0038] (3) Cut single-layer nickel foam with a direct slicer, a 10mm diameter disc, take a piece and put it into the mold; it is also called the foam that 6.67mg of metal heterogeneous particles / reduced graphene oxide composite material is evenly sprinkled in the mol...

Embodiment 3

[0041] (1) 100mg graphene oxide and 100mg 1-methyl-3-ethylimidazole dihydrogen phosphate (EMIMH 2 PO 4 ) into a 25mL round-bottomed flask, stirred evenly, and ultrasonicated at room temperature for 1 hour; then added 10 mg of chloroauric acid, and continued ultrasonication for 0.5 hour to obtain a brown mixture;

[0042] (2) Add 0.2 g of sodium citrate to the mixture obtained in step (1), stir evenly, transfer to a 25 mL polytetrafluoroethylene reactor, and place it in a thermostat at 150° C. for 20 hours to obtain a gel-state mixture . After washing the gel-state mixture with deionized water, place it in a freeze dryer for 48 hours to obtain a metal heterogeneous particle / reduced graphene oxide composite material;

[0043] (3) Cut single-layer nickel foam with a direct slicer, a 10mm diameter disc, take a piece and put it into the mold; it is also called the foam that 6.67mg of metal heterogeneous particles / reduced graphene oxide composite material is evenly sprinkled in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com