Array substrate, preparation method thereof and display device

A technology for array substrates and display areas, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of dark lines in the display area, and achieve the effect of avoiding dark lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] As mentioned in the background, dark lines are easily generated in the display area of the array substrate in the prior art.

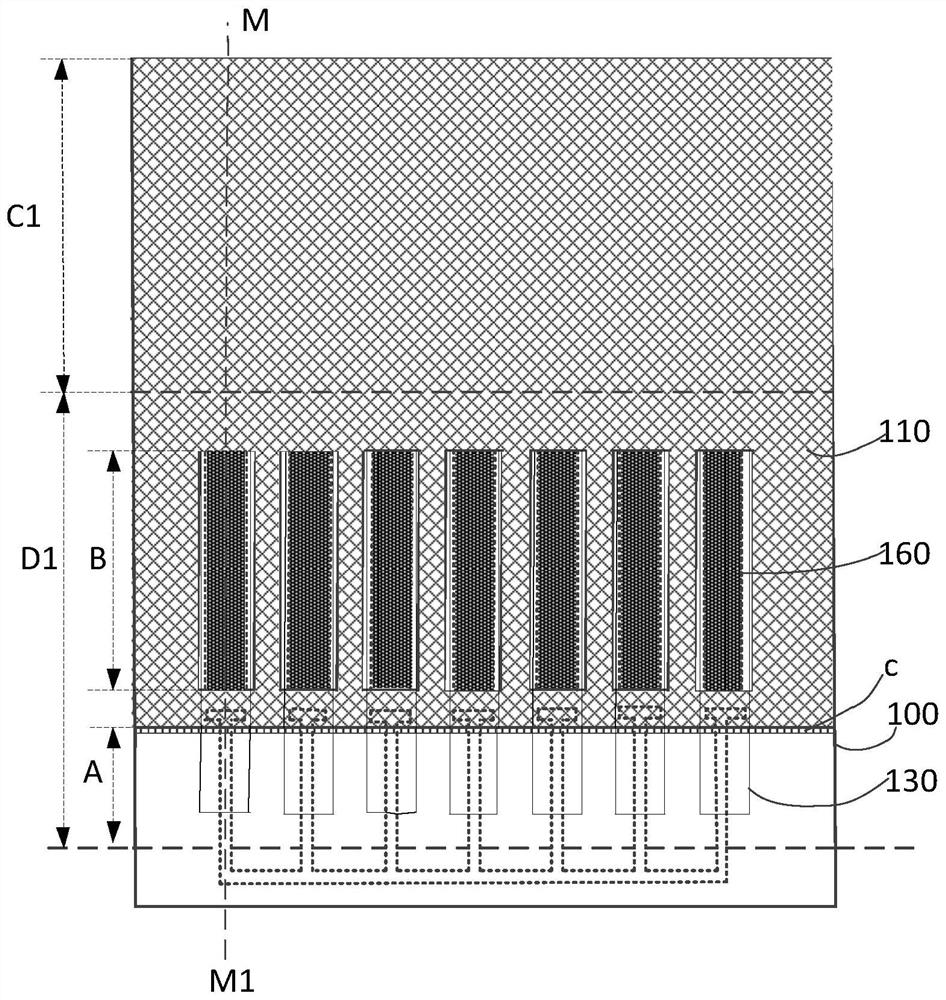

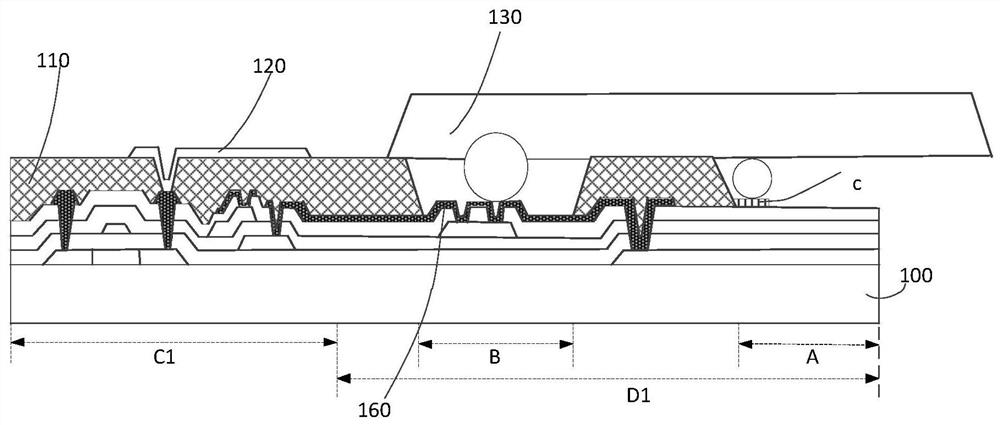

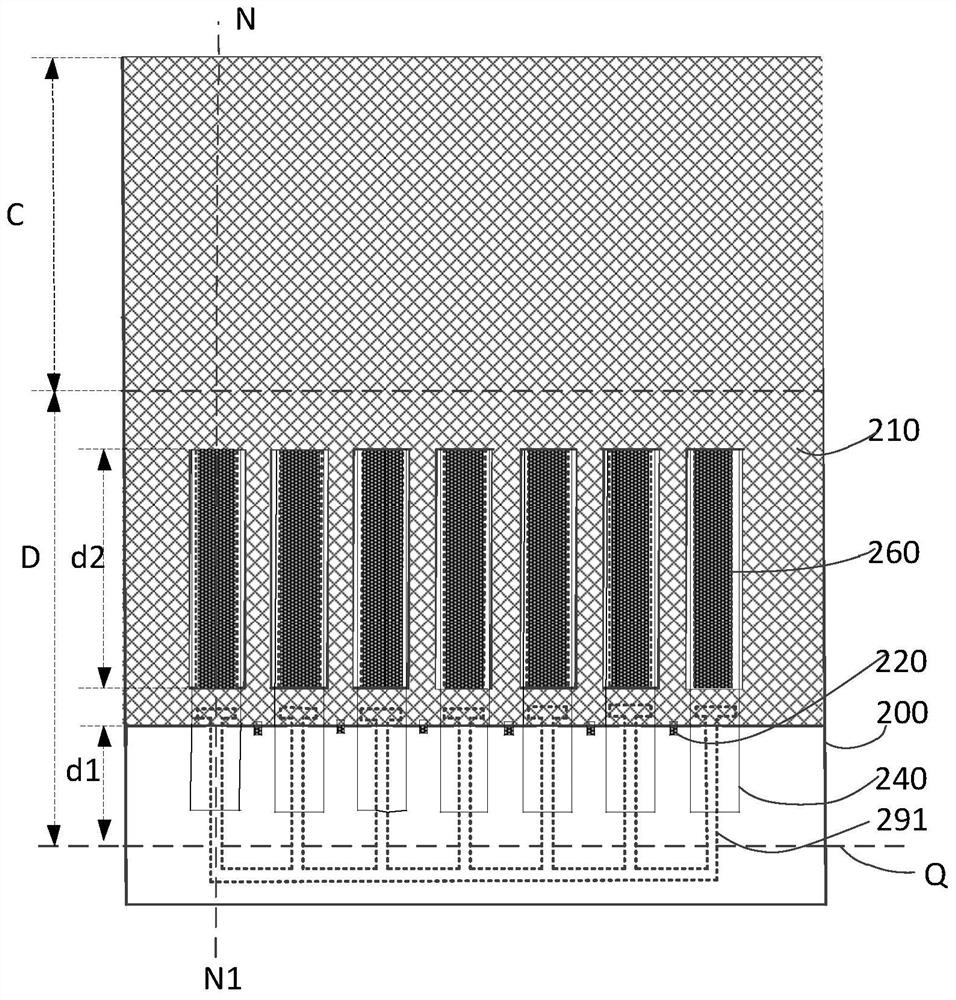

[0036] An array substrate, combined with reference figure 1 with figure 2, including: a base substrate 100, the base substrate 100 includes a display area C1 and an edge area D1, the edge area D1 includes a cutting reserved area A and a binding area B, and the binding area B is located on the display between the area C1 and the reserved area for cutting; the planarization layer 110 located on the display area C1 and the edge area D1, and the planarization layer 110 exposes the reserved area for cutting and the Binding area B; anode layer 120, located on the display area C1 and on the surface of the planarization layer 110 away from the base substrate 100; electrically connected to the conductive connection line 160 of the binding area B There are several bonding connection lines 130 , and the bonding connection lines 130 extend from the bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com