Dedusting and purifying device for underground tunneling working area

A technology for excavation work and purification device, applied in the directions of safety device, dust prevention, transportation and packaging, etc., can solve problems such as affecting the health and work efficiency of workers, single function, stagnation of dust removal work, etc., to achieve easy repair and maintenance, The effect of high dust removal efficiency and large dust removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

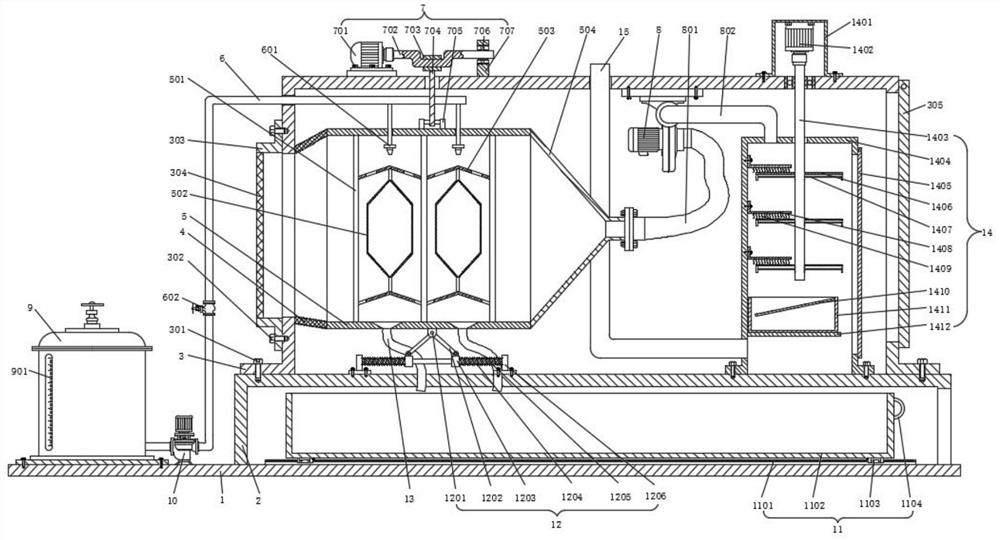

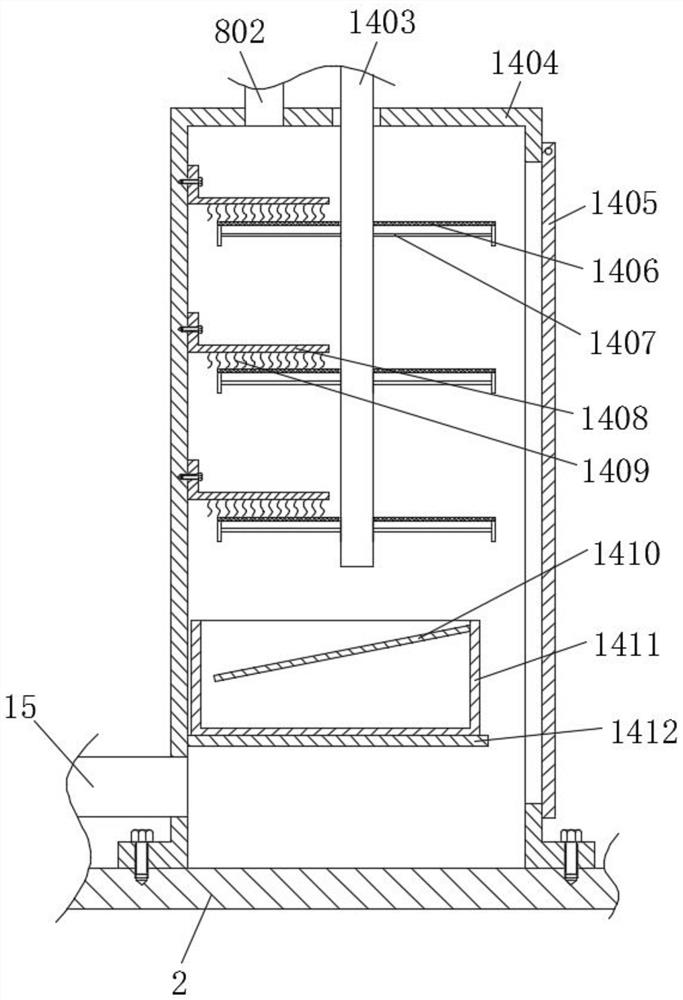

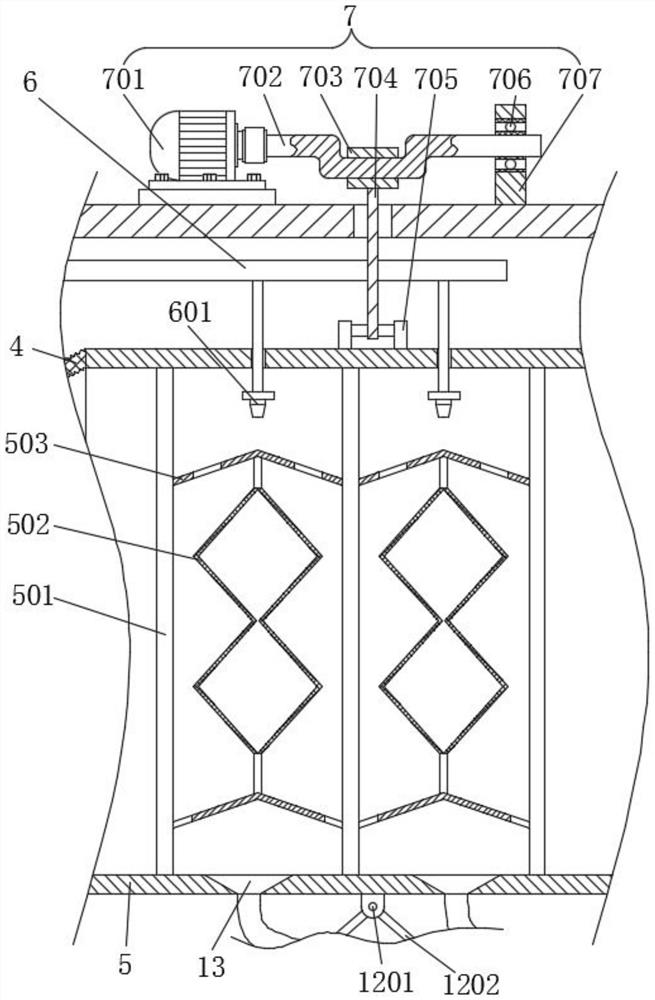

[0028] Such as Figure 1-Figure 5As shown, the specific structure of the present invention is: a dust removal and purification device for underground excavation work areas, including a base plate 1, on which a liquid storage tank 9, a liquid suction pump 10, a support frame body 2, and a support frame body are sequentially arranged. 2. The upper end is connected to the chassis cover 3 through the first screw 301. The movable box 5 is arranged inside the chassis cover 3. The upper end and the lower end of the movable box 5 are respectively provided with a drive assembly 7 for driving the vertical recipr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com