Tunnel surrounding rock advanced horizontal water stop grouting construction method

A technology of horizontal water stop and construction method, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of insufficient grouting, inability to completely fill tunnel seepage channels, poor reinforcement effect, etc., and achieve the effect of ensuring surrounding rock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

[0017] This embodiment provides an advanced horizontal water-stop grouting construction method for tunnel surrounding rock, and the specific process is as follows:

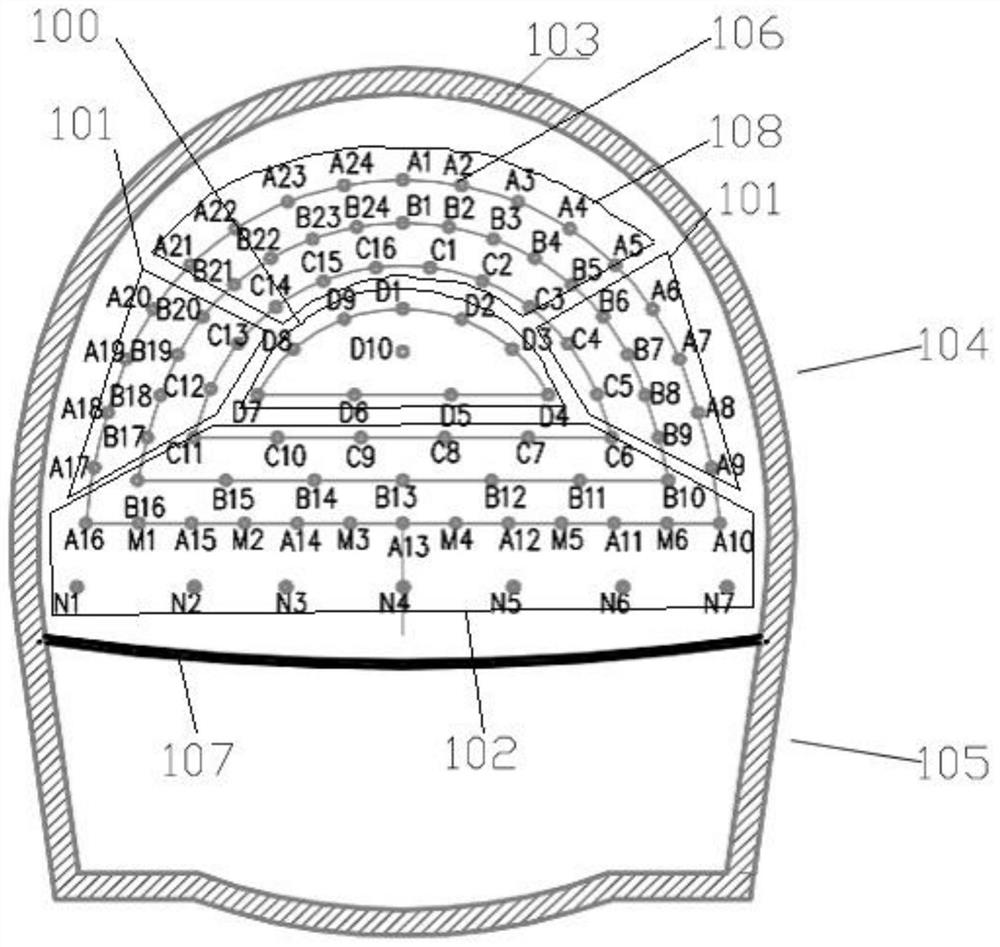

[0018] Within the set reinforcement area, the grouting holes 106 are arranged and grouted across the entire section, including the excavation area 100 and the vault area 108 around the tunnel, the side areas 101 and the inverted arch area 102 are all laid out and grouted Hole and grout. After a single grouting hole is drilled, it is grouted, and after the grouting is completed, the next grouting hole is drilled. figure 1 Shown is a schematic diagram of the step ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com