Fabricated building cantilever discharging platform and construction method thereof

An unloading platform and prefabricated technology, applied in the processing of building materials, construction, building structure, etc., can solve the problem that it is difficult to meet the safety and cleanliness of prefabricated buildings. and other problems to achieve the effect of avoiding the legacy of steel bars, reducing labor input, and cleaning labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

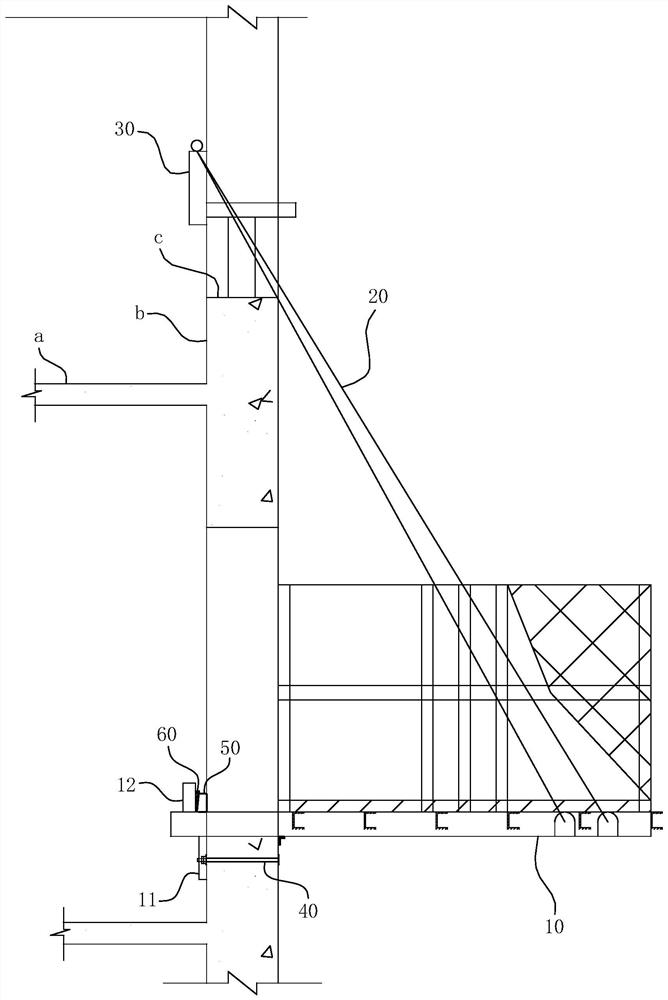

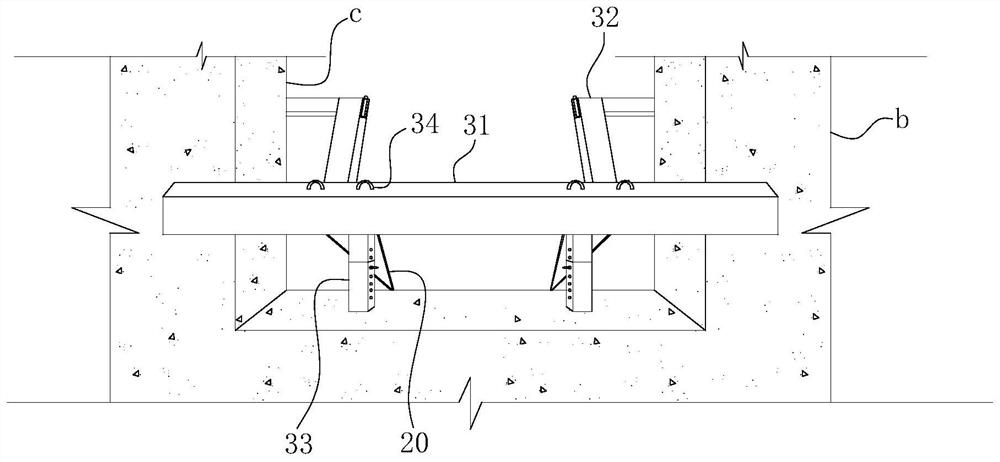

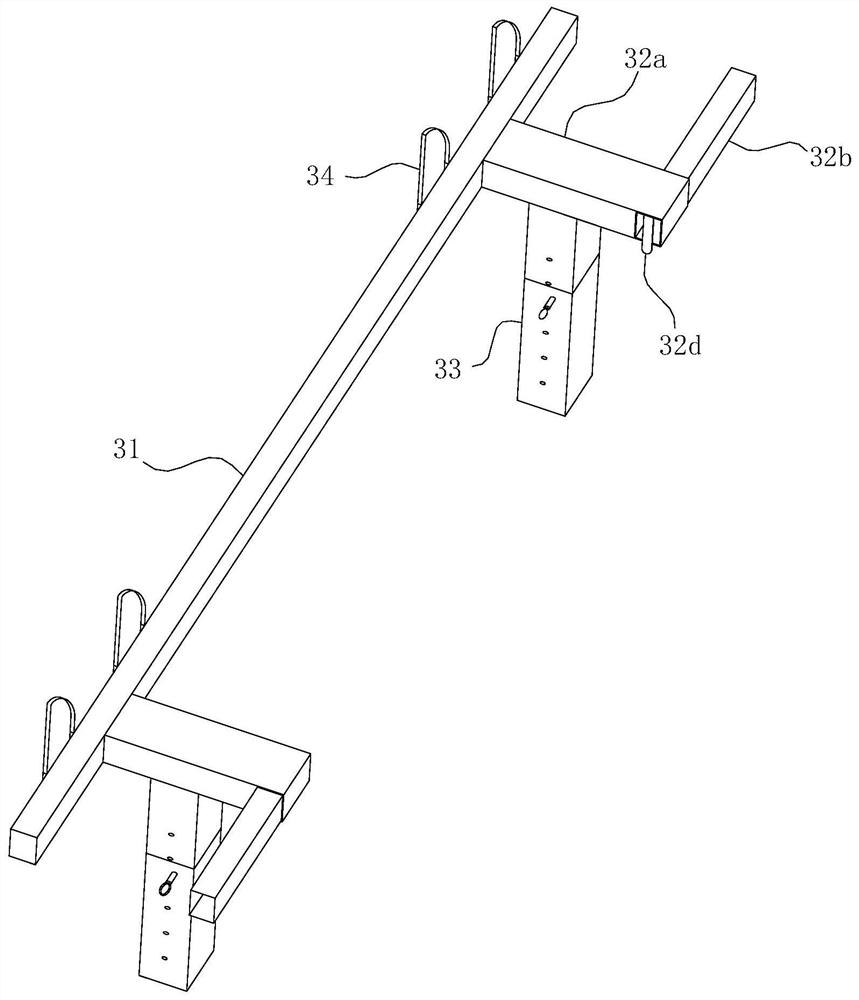

[0041] For ease of understanding, the attached Figure 1-4 , the concrete structure and working mode of the present invention are further described as follows:

[0042] The specific structure of the present invention refers to figure 1 As shown, it is mainly composed of three parts: platform part 10, suspension rope 20 and combined pull rod 30. Wherein, the platform part 10 can adopt such as figure 1 The platform configuration shown. As for the overhanging section of the platform portion 10, it needs to be as follows: figure 1 The one shown extends beyond the window sill at the floor a of the current floor structure, so as to realize the shelving and transshipment of materials.

[0043] On the basis of the above structure, such as figure 1 As shown, the present invention symmetrically arranges two suspension ropes 20 at both sides of the cantilever section of the platform part 10, one end of the two suspension ropes 20 is fixedly connected to the cantilever section, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com