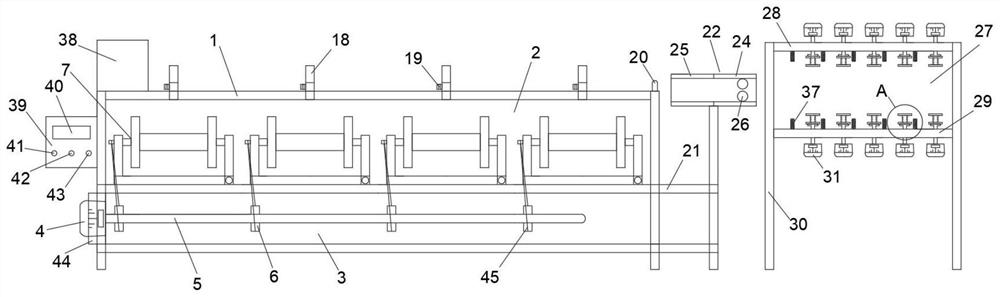

[0005] (1) Introduce nylon wire or other insulating materials and rubber strips from the wire splitting teeth through the pay-off

assembly, start the speed-regulating motor, and the speed-regulating motor drives the rotating gear on the rotating shaft to rotate, and the belt on the rotating gear drives the outer belt on the joint assembly. The shaft rotates, and the rotation of the outer shaft drives the nylon wires or other insulating materials on multiple spools to be plied with the rubber strips. Through the above structure settings, in the process of plying the rubber strips, the insulation between the rubber strips and the nylon wires or other insulation materials is effectively improved. The efficiency of material plying avoids the situation that a single spool and can only be plied with a single material, resulting in slow subsequent

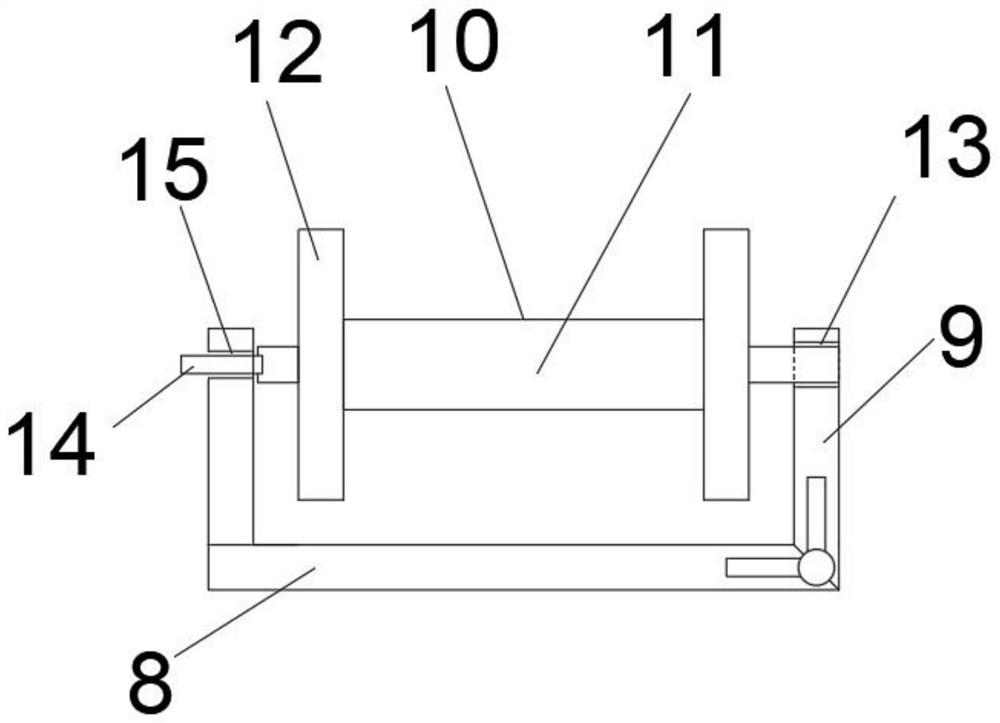

processing efficiency; (2) After the rubber strip and nylon wire or other insulating materials are fully wound on the spool, the swinging block is moved to make The oscillating block hingedly connected by the

fixed frame rotates to the right, and the right end of the outer shaft is equipped with a fitting structure that matches the inside of the left end of the

bobbin. Move the wire take-up assembly to the right and take it out, replace it with a new wire take-up assembly and install it on the joint assembly , the spool is engaged with the outer shaft in the

pipe at the left end of the

fixed frame. After moving the wire take-up assembly to the middle of the

fixed frame, swing the swing block so that the swing block hingedly connected by the fixed frame turns to the left until the right end of the

bobbin meets the inside of the swing block. Through the above-mentioned setting of the take-up assembly, the take-up assembly can be disassembled in time after the nylon wire or other insulating material and the rubber strip are fully rolled, which not only improves the output of the plying machine, but also improves the take-up assembly. When installing, use the left end of the

bobbin to connect with the outer shaft, the hinged connection between the swinging block and the fixed frame, and the outer end of the bobbin to fit the hole of the swinging block, which increases the simplicity of the plying machine and reduces the number of rubber strips in the plying machine during the

processing of the plywood strips.

Mechanical failure caused by overflow after the roll is full; (3) Before the nylon wire or other insulating materials and rubber strips enter the

branch teeth, the nylon wires or other insulating materials and rubber strips are introduced into the micro-heating box through the lead shaft in the pay-off assembly At the opening of the right end, the guide wheels at the upper and lower ends of the right side of the micro-heating box make the nylon wire or other insulating materials and rubber strips pull in the middle of the micro-heating box, and the first and second

thermal resistance wires at the upper and lower ends of the micro-heating box are aligned. The nylon wire or other insulating materials and rubber strips in the middle are slightly heated. During the slight heating process of nylon wires or other insulating materials and rubber strips, the

viscosity of the rubber strips softens and increases, achieving the effect of preliminary joint stock. Through the above structure settings, Slight heating of nylon wire or other insulating materials and rubber strips speeds up the next step of the joint process, which enhances the effect of the joint machine. The wire or other insulating materials and rubber strips move to the middle of the micro-heating box, on the one hand, it solves the problem of uneven heating of the rubber strips, and on the other hand, it facilitates the preliminary jointing of nylon wires or other insulating materials and rubber strips; (4) Pay-off wheel The second groove inside is matched with the second bump of the pay-off shaft. After the nylon wire or other insulating materials and rubber strips are placed, the pay-off wheel can be replaced, which makes it easy to replace the pay-off wheel and improves the release speed. Line efficiency, to further improve the efficiency of the jointing machine, the stop pad on one side of the pay-off shaft is elastic, and during the pay-off process, the stop pad blocks one end of the pay-off wheel, avoiding the winding accident caused by the vibration of the pay-off wheel. Through the driving motor on one side of the upper pay-off plate or the lower pay-off plate, the pay-off mode is changed to active pay-off, which reduces the force of the pay-off wheel on the reel wheel and the bobbin; (5) Nylon wire or other insulating materials After passing through the splitting teeth with the rubber strip, it winds around the lead wheel and the rerouting wheel and enters the bobbin for plying and winding. The interval between each lead wheel of the lead wheel group on the top of the upper shelf increases gradually from left to right, so that the rubber strip and the

nylon thread The types of material lines such as

silica gel and

silica gel have increased, which is conducive to the diversity of rubber strip processing and joint

stocking, and has enriched the product types of rubber strips for the joint machine. The accuracy of the machine's joint stock has improved the

production quality of the joint stock machine product

Login to View More

Login to View More  Login to View More

Login to View More