PVD coating method and PVD coating device

A coating device and coating technology, applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems that the same time cannot be guaranteed, the color of the film is uneven, and the uniformity of the thickness of the film layer is affected. Improved film thickness uniformity, simple structure, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

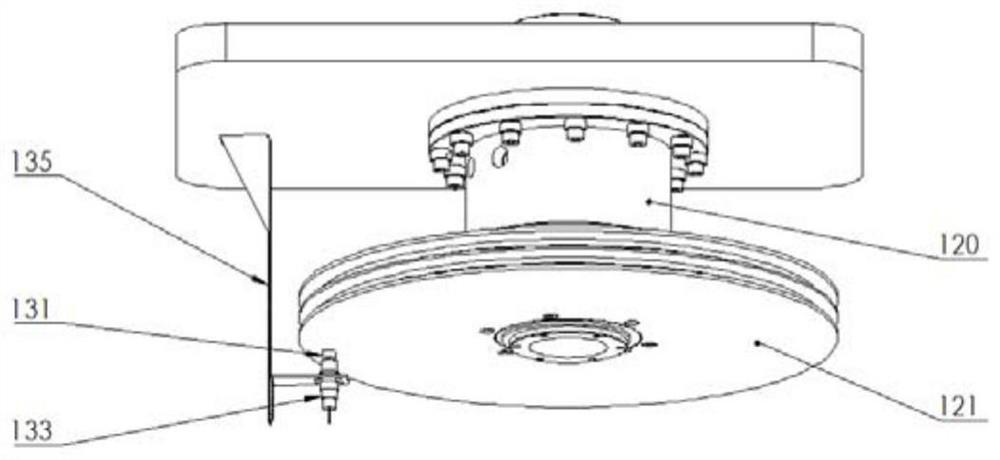

[0094] Embodiment 1 uses a PVD coating device to deposit and form a color layer

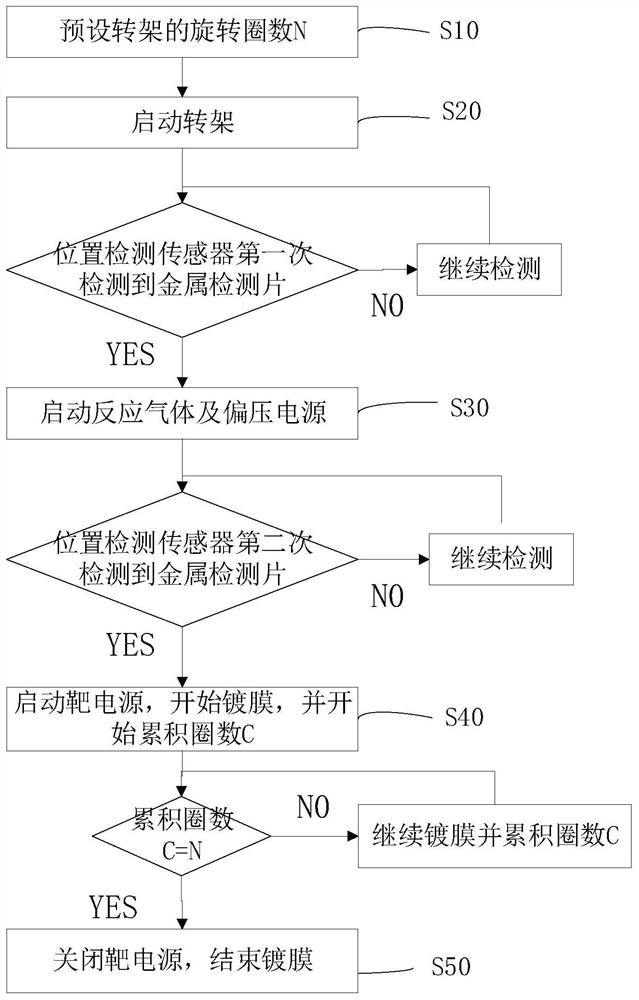

[0095] 1) Set the number of rotations of the turret to 36.

[0096] 2) Start the control program, start the turret, and when the position detection sensor detects the metal detection piece for the first time, turn on the working gas and the reaction gas, feed the working gas and the reaction gas into the vacuum coating chamber, and turn on the bias power supply; When the position detection sensor detects the metal detection piece for the second time, turn on the power of the target, and start to accumulate the number of turns of the turret rotation. When the position detection sensor detects the metal detection piece again, it will accumulate 1 circle.

[0097]3) When the cumulative number of turns reaches 36 turns, the coating control module turns off the target power supply and bias power supply in sequence, stops feeding the working gas and reaction gas, and turns the frame to complete the coa...

Embodiment 2

[0101] Embodiment 2 adopts PVD coating device to deposit and form color layer

[0102] 1) Set the number of rotations of the turret to 48.

[0103] 2) Start the control program, start the turret, and when the position detection sensor detects the metal detection piece for the first time, turn on the working gas and the reaction gas, feed the working gas and the reaction gas into the vacuum coating chamber, and turn on the bias power supply; When the position detection sensor detects the metal detection piece for the second time, turn on the power of the target, and start to accumulate the number of turns of the turret rotation. When the position detection sensor detects the metal detection piece again, it will accumulate 1 circle.

[0104] 3) When the cumulative number of laps reaches 48, the coating control module turns off the target power supply and bias power supply in sequence, stops feeding the working gas and reaction gas, and turns the frame to complete the coating. Th...

Embodiment 3

[0106] Embodiment 3 adopts PVD coating device to deposit and form color layer

[0107] 1) Set the number of turns of the turret to 96.

[0108] 2) Start the control program, start the turret, and when the position detection sensor detects the metal detection piece for the first time, turn on the working gas and the reaction gas, feed the working gas and the reaction gas into the vacuum coating chamber, and turn on the bias power supply; When the position detection sensor detects the metal detection piece for the second time, turn on the power of the target, and start to accumulate the number of turns of the turret rotation. When the position detection sensor detects the metal detection piece again, it will accumulate 1 circle.

[0109] 3) When the cumulative number of turns reaches 96 turns, the coating control module turns off the target power supply and bias power supply in turn, stops feeding the working gas and reaction gas, and turns the frame to complete the coating. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com