Preparation method of ultralow-viscosity vinyl silicone oil

A technology of vinyl silicone oil and ultra-low viscosity, which is applied in the field of preparation of ultra-low viscosity vinyl silicone oil, which can solve problems such as difficult to achieve, and achieve the effect of meeting synthesis requirements, stable storage, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

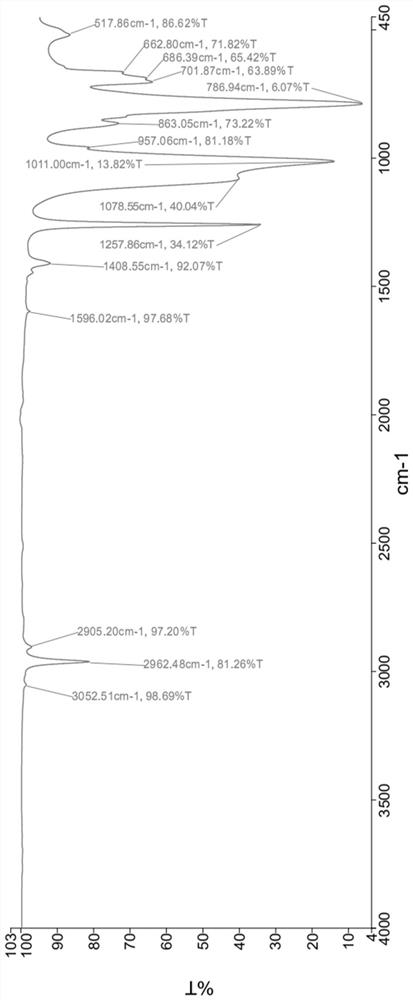

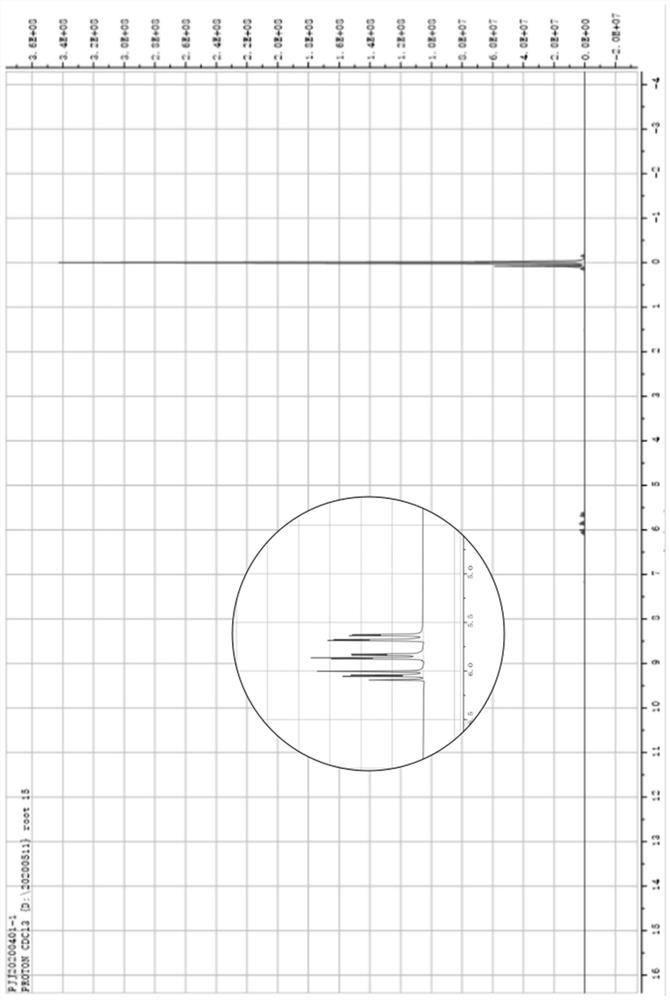

Image

Examples

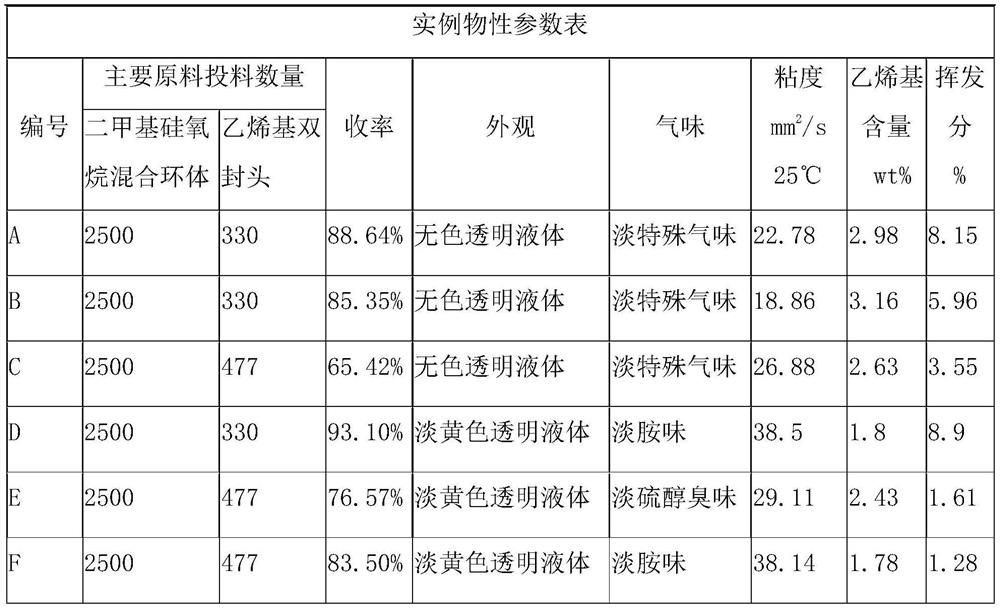

Embodiment 1

[0025] Add 2500g of dimethylsiloxane mixed ring body to the flask, vacuumize at 75°C for 1 hour, then add 330g of tetramethyldivinyldisiloxane at room temperature, then add 1.25g of acid catalyst, start to heat up, 40 Stir and react at a constant temperature for 12 hours, then add 4g of sodium bicarbonate to neutralize and react for 2 hours, filter with negative pressure medium-speed filter paper to obtain a colorless transparent liquid, and finally remove the components at a constant temperature of 150°C for 2 hours to obtain ultra-low viscosity vinyl Silicone oil A.

Embodiment 2

[0027] Add 2500g of dimethylsiloxane mixed ring body to the flask, vacuumize at 75°C for 1 hour, drop to room temperature, add 330g of tetramethyldivinyldisiloxane, then add 1.25g of acidic catalyst, and start to heat up to 80°C ℃, stirred at constant temperature for 5 hours, then added 4g of sodium bicarbonate to neutralize and reacted for 1 hour, then filtered through negative pressure medium-speed filter paper to obtain a colorless transparent liquid, and finally removed components at a constant temperature of 150°C for 3 hours to obtain ultra-low viscosity ethylene base silicone oil B.

Embodiment 3

[0029] Add 2500g of dimethylsiloxane mixed ring body to the flask, vacuumize at 75°C for 1 hour, drop to room temperature, add 477g of tetramethyldivinyldisiloxane, then add 95g of cation exchange resin, and start to heat up to 80 React at ~100°C for 12 hours. After the reaction is completed, filter out the cation exchange resin (reusable) to obtain a colorless transparent liquid, and then raise the temperature to 180°C with nitrogen gas to remove components at a constant temperature for 1 hour to obtain ultra-low viscosity vinyl silicone oil C. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com