Intelligent board machining center with embedded part mounting device

A technology of intelligent processing and embedded parts, which is applied in the direction of wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve the problems of inability to punch holes in wood boards, speed up punching, and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

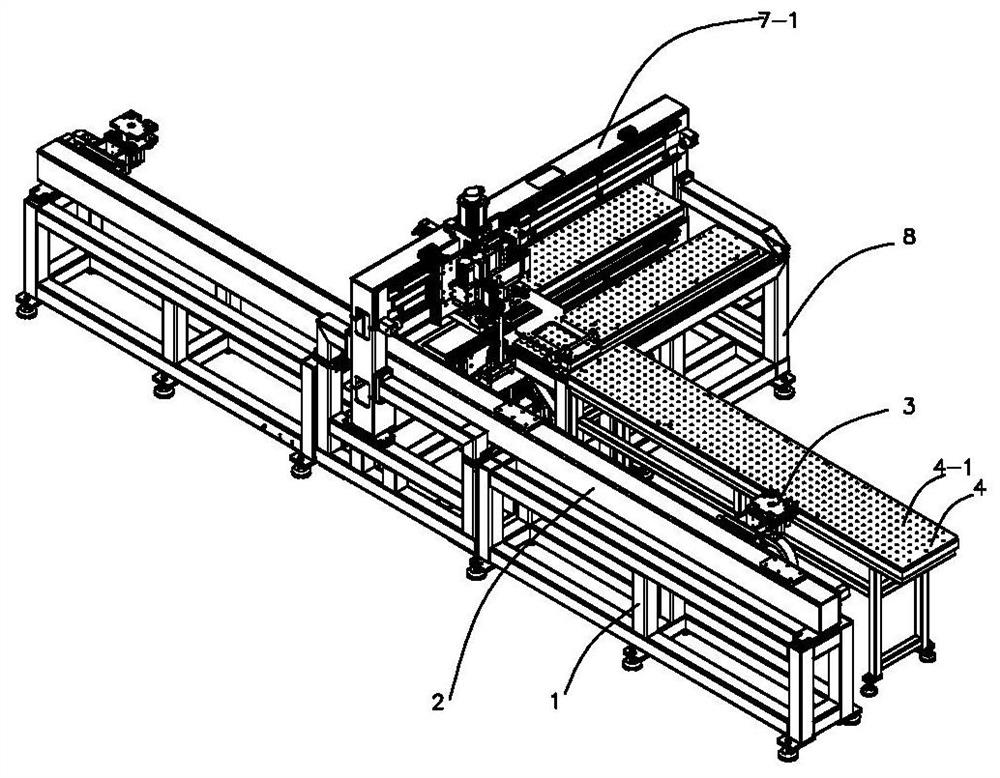

[0063] For ease of description, the orientation references of "up", "down", "left", "right", "front" and "rear" in the present invention are attached figure 1 The orientation shown shall prevail;

[0064] An intelligent board processing center with a device for punching embedded parts, including a clamping mechanism, an edge cleaning mechanism, an upper drilling mechanism and a lower drilling mechanism, the clamping mechanism is used to clamp and move wooden boards to be processed; the edge cleaning mechanism It is used to process the datum planes in the Y-axis direction and X-axis direction adjacent to the wooden board to be processed; the upper drilling mechanism is used for processing the front, rear, left, right and upper planes of the wooden board to be processed, and the lower drilling mechanism It is used for processing the lower plane of the wood panel to be processed.

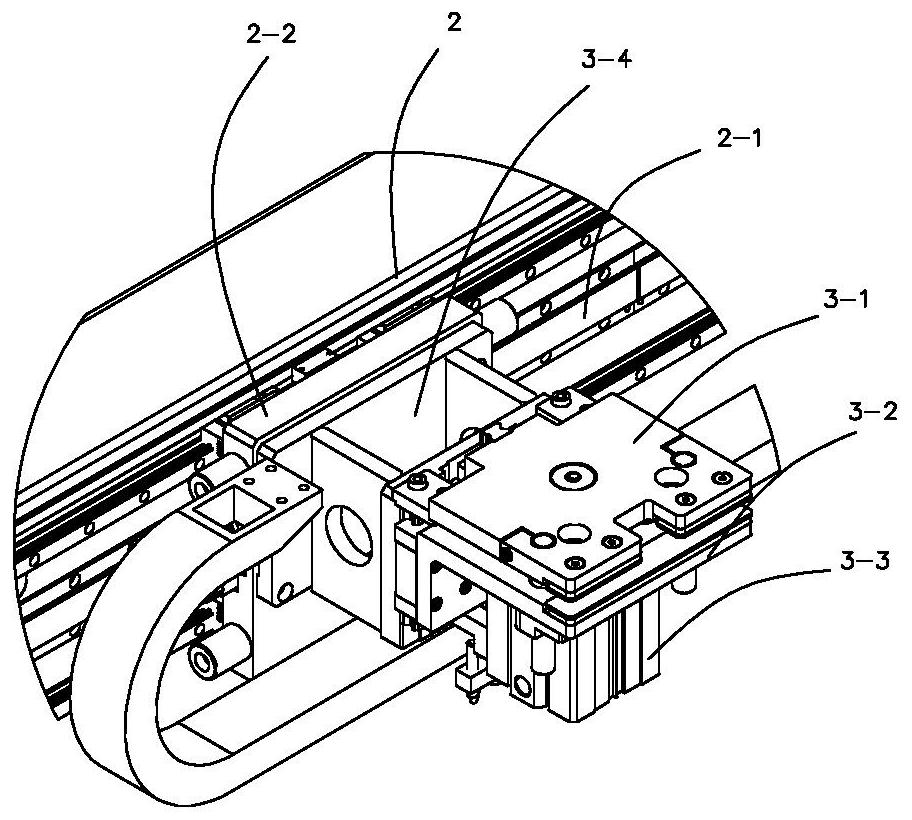

[0065] Such as figure 1 As shown, the clamping mechanism includes a first frame 1, a longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com