Hemispherical resonator inner spherical surface accurate grinding wheel

A fine grinding wheel and harmonic vibrator technology, applied in the direction of bonded grinding wheels, abrasives, metal processing equipment, etc., can solve the problems of difficulty in ensuring accuracy and low processing efficiency, and achieve the goals of reducing processing force, high processing efficiency, and improving processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

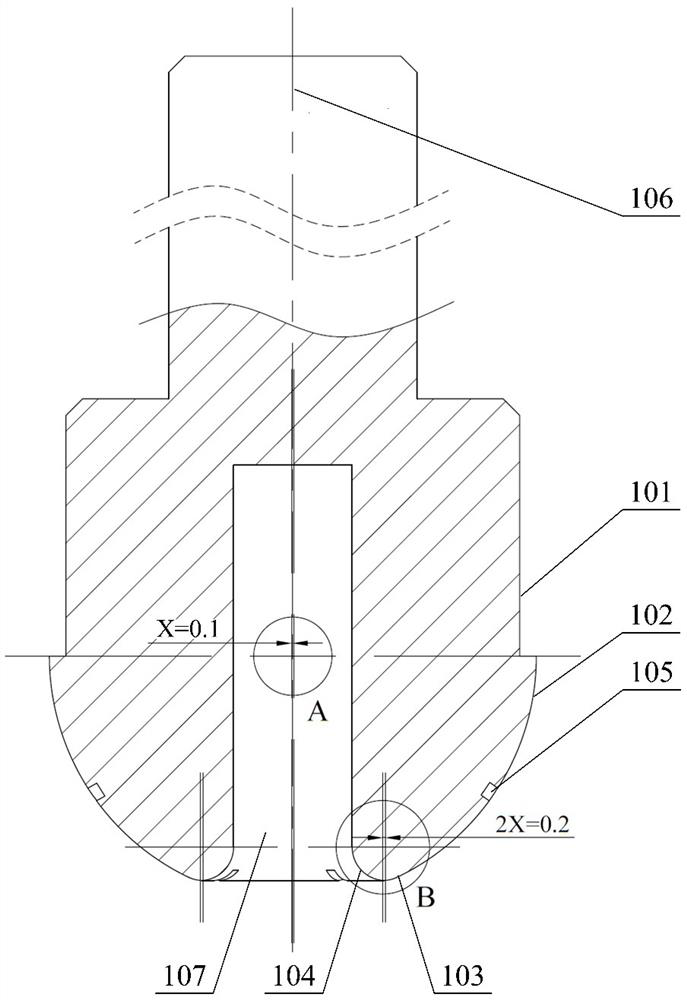

[0025] Attached below Figure 1~4 , taking the processing of the inner circle of the quartz resonator with inner spherical radius R1=15 mm and inner fillet R2=2 mm as an example, the present invention will be further described.

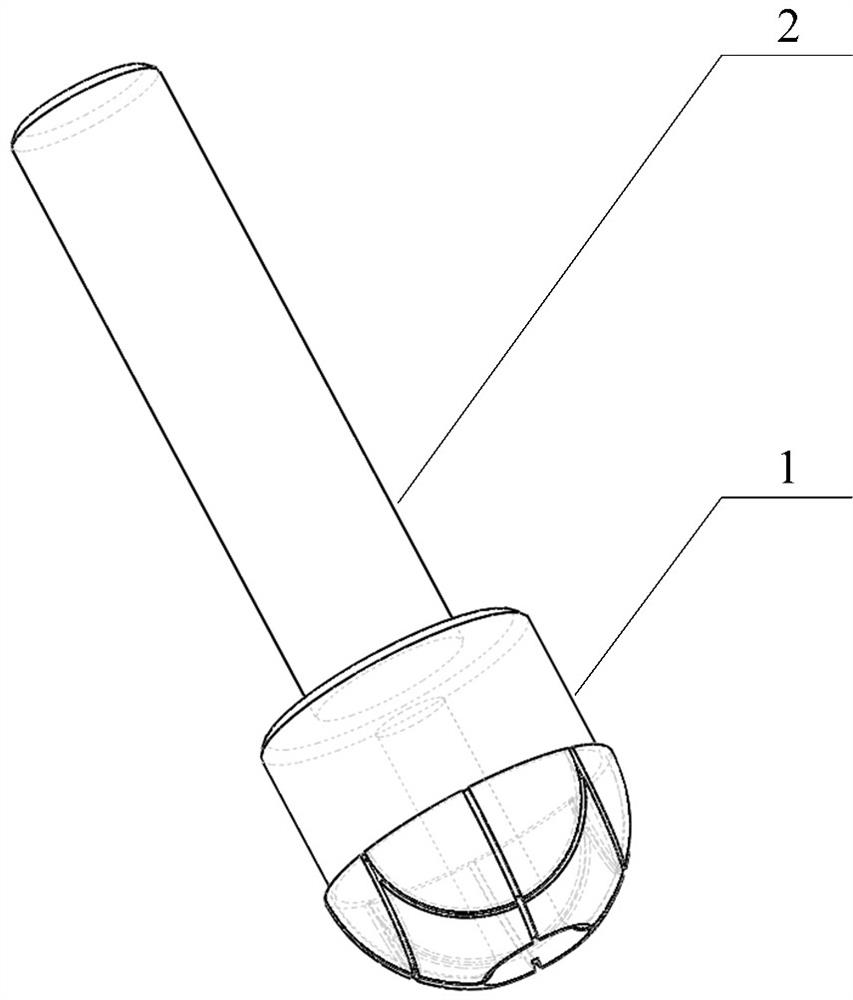

[0026] A fine-grinding grinding wheel for the inner spherical surface of a quartz resonator, which is used for the fine grinding of the inner sphere of the quartz resonator. The inner circular surface of the processed quartz resonator includes the inner sphere of the quartz resonator and the fillet of the quartz resonator. It is characterized in that: The fine grinding wheel consists of a processing section 1 and a holding shaft 2 .

[0027] The processing section 1 includes a cylinder section 101 , an arc section 102 , a fillet section I 103 and a fillet section II 104 .

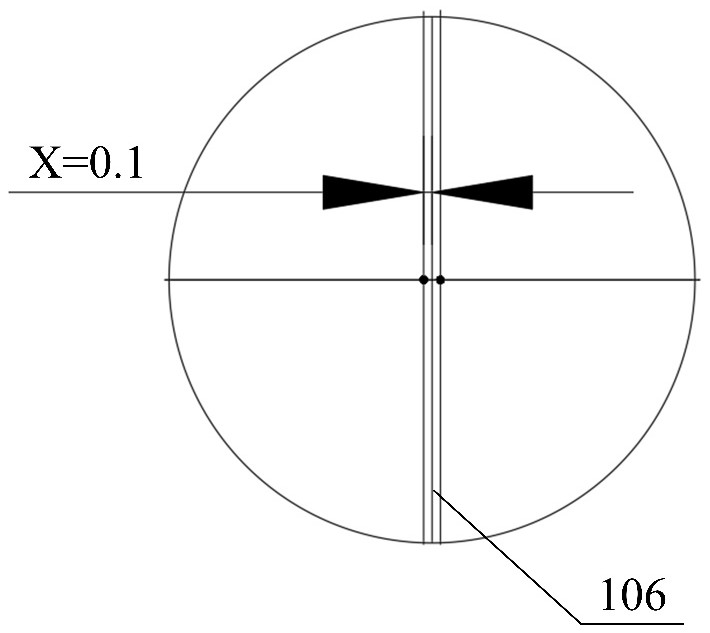

[0028] The height of the cylindrical section 101 is greater than the height of the smallest diameter section of the central rod on the quart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com