Annular adjustable positioning tool

A positioning tool and ring technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of scrap parts, inaccuracy, and difficulty in alignment, and reduce downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

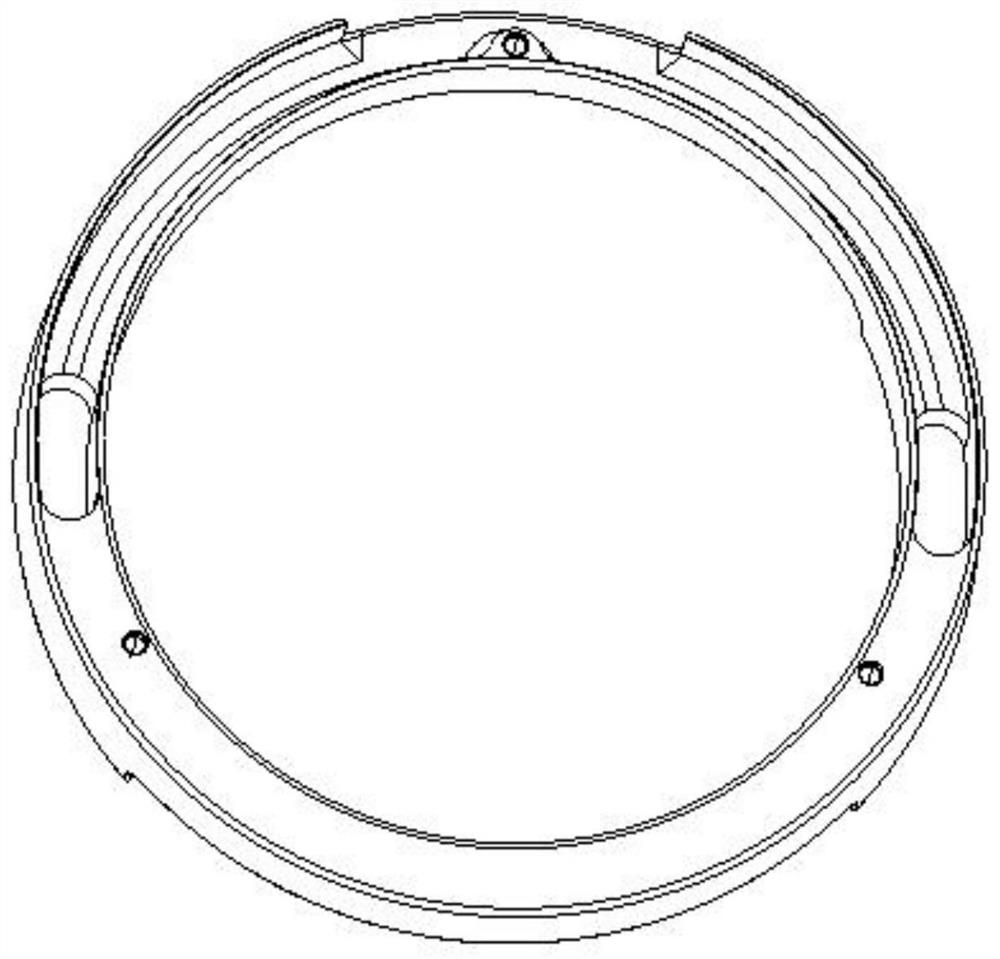

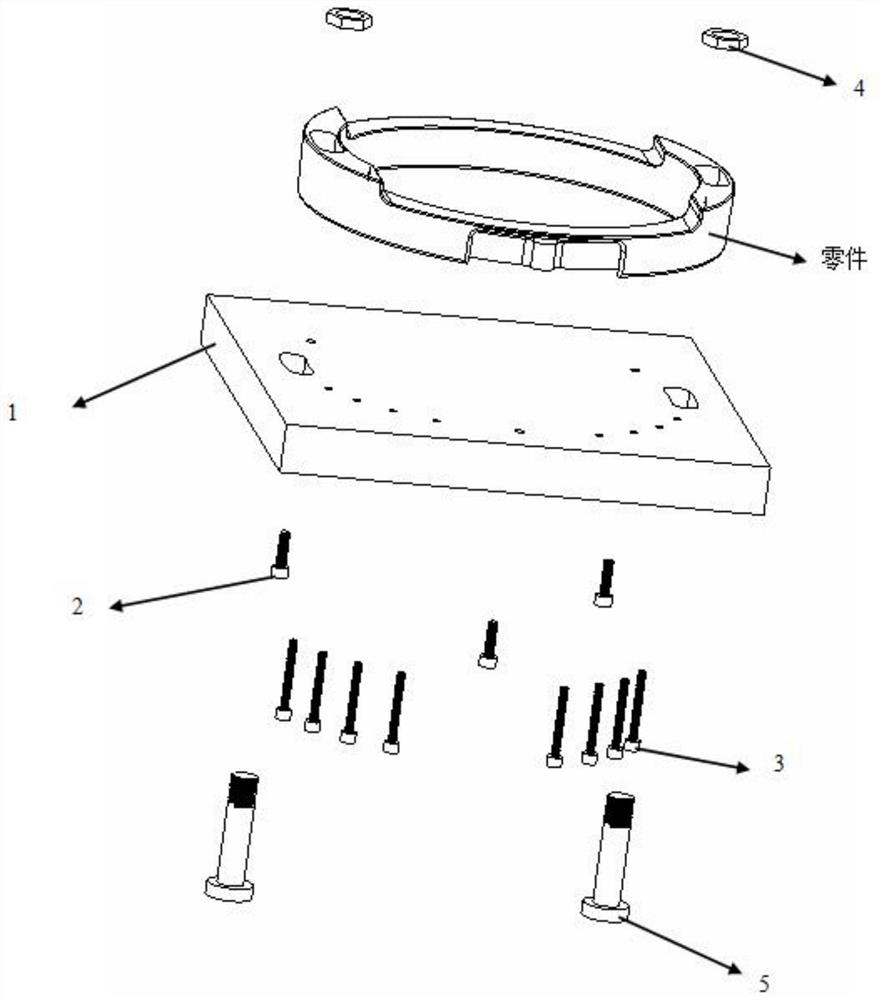

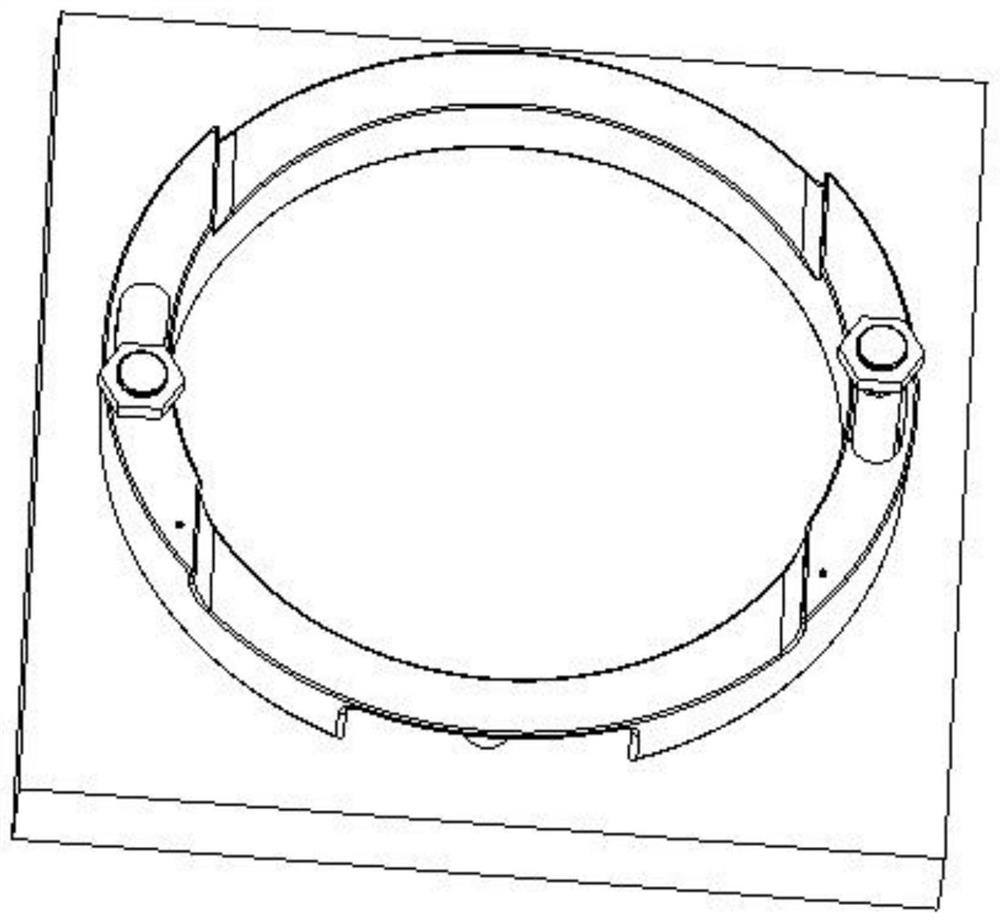

[0013] Attached below Figure 1-3 The present invention is described in detail.

[0014] An annular adjustable positioning tool, including a bottom plate 1, two arc-shaped grooves are arranged on the bottom plate 1, and an adjustable positioning pin 5 is installed in the arc-shaped groove, and the adjustable positioning pin 5 penetrates the part and connects with the nut 4 Screw connection, fix the parts on the bottom plate 1, the positioning pins in the two arc-shaped grooves can adjust different positions according to the parts, and are suitable for parts of different shapes; there are multiple threaded holes on the bottom plate 1, screwed into the threaded holes The reverse locking screw 2 and the adjustable support screw 3; the reverse locking screw 2 is threadedly connected with the part, and the adjustable support screw 3 is in contact with the part to support the thin-walled part and avoid chattering of the knife.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com