Heat treatment robot clamping device based on 3D laser scanning

A laser scanning, laser scanner technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., to achieve the effect of compatible clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

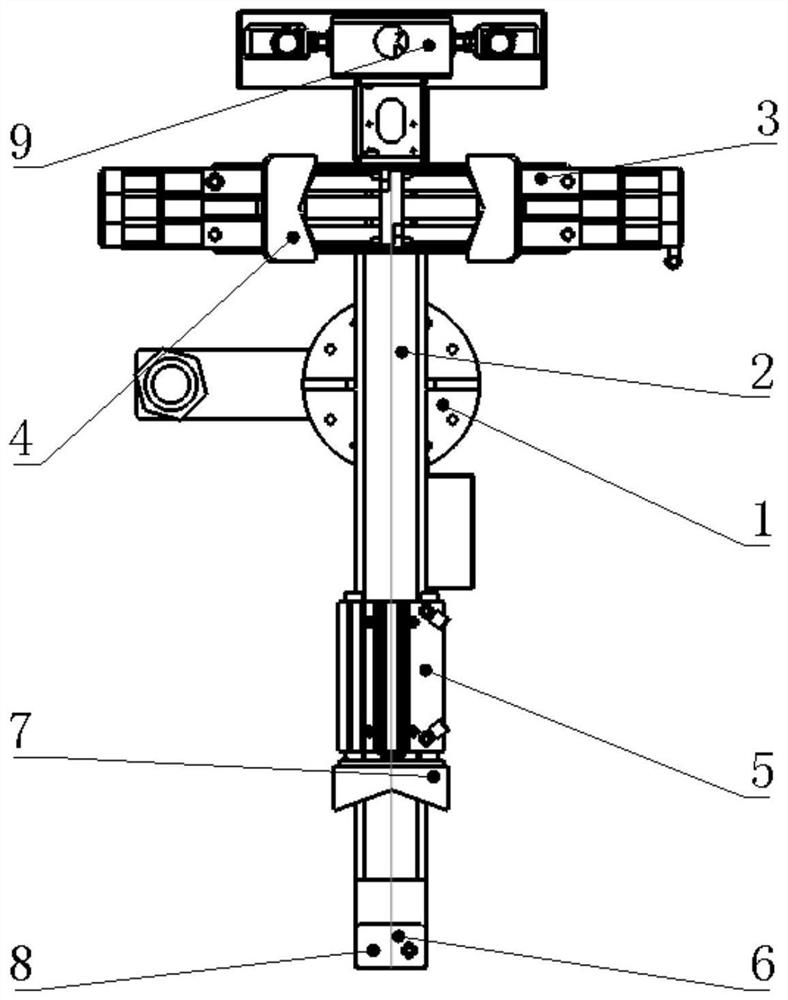

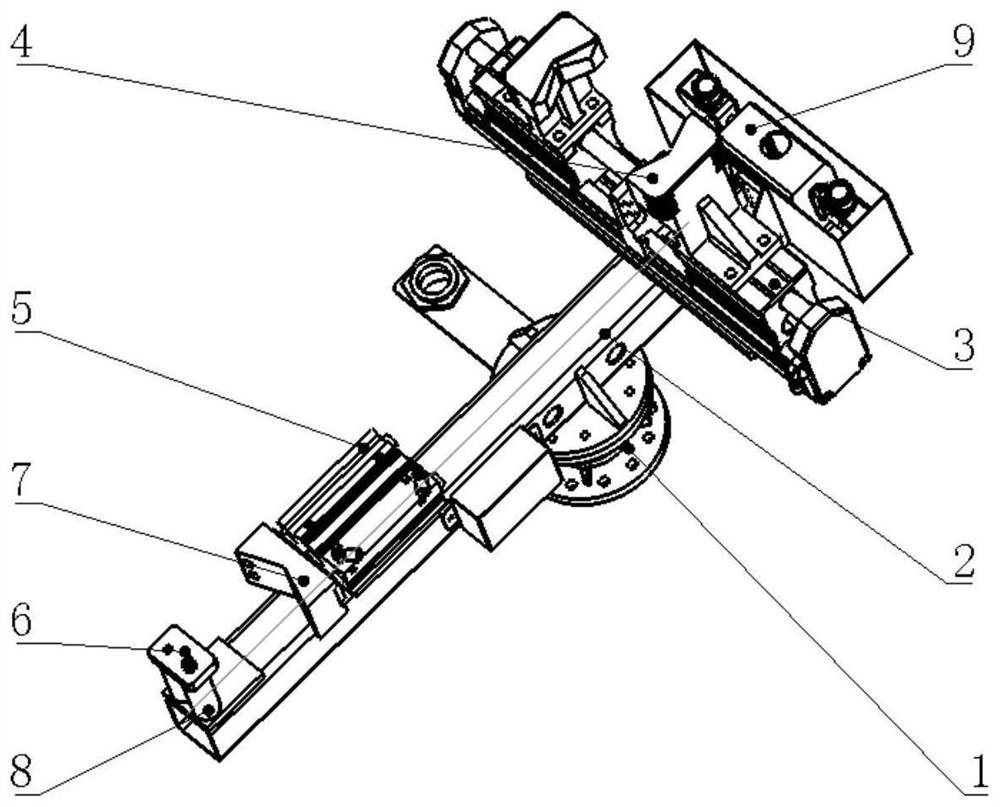

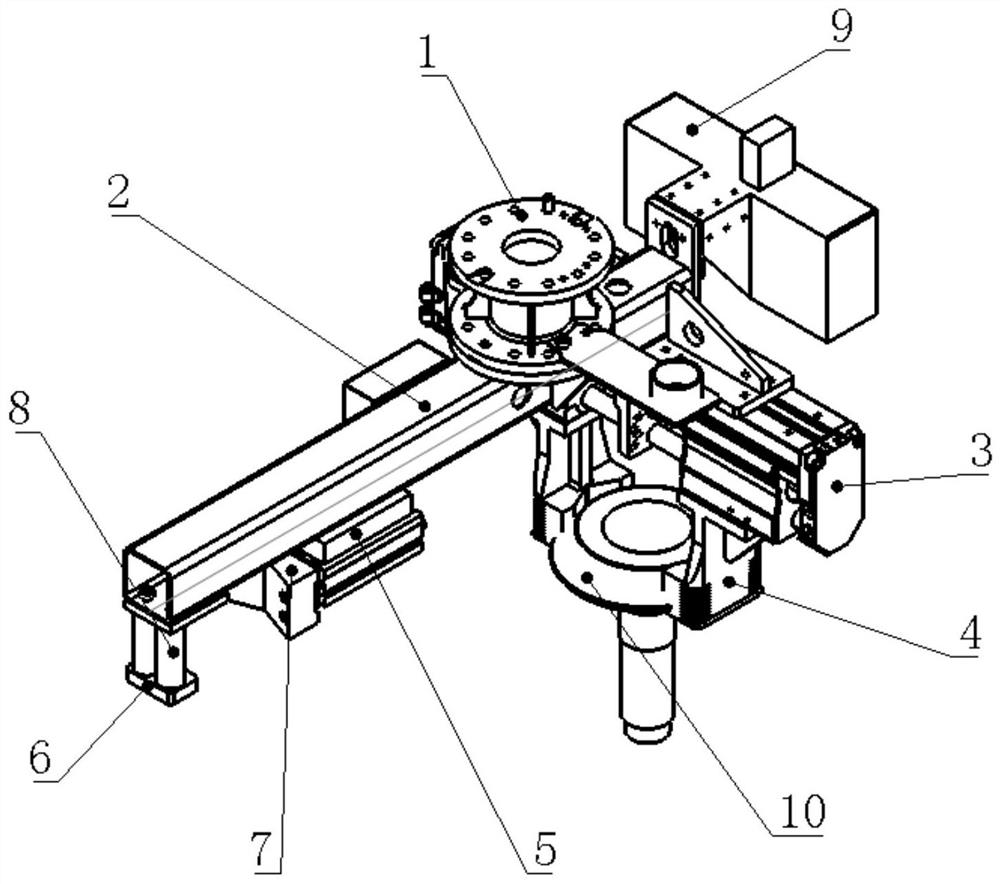

[0017] A heat treatment robot clamping device based on 3D laser scanning of the present invention includes a robot mounting flange plate 1, a mounting base 2, parallel air claws 3, a clamping block 4, a cylinder 5, a connecting plate 8, and a V-shaped positioning block 7 , blocking block 6, 3D laser scanner 9, workpiece 10;

[0018] The robot installation flange plate 1 is used to be fixed at the end of the six-axis robot; the installation base 2 is fixedly connected with the robot installation flange plate 1; the installation base 2 is fixed with a cylinder 5, and the cylinder 5 push rod is connected to the V-shaped The positioning block 7 is connected; at the position facing the V-shaped positioning block 7, a connecting plate 8 is fixed on the installation base 2, and the blocking block 6 and the connecting plate 8 are fixedly connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com