Die cutter splicing device and method of full-automatic bending equipment

A fully automatic, bending die technology, applied in the field of sheet metal bending, can solve the problems of affecting processing accuracy, unable to meet the needs of small batch and multi-variety processing, and low degree of intelligence, and achieve the effect of improving processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

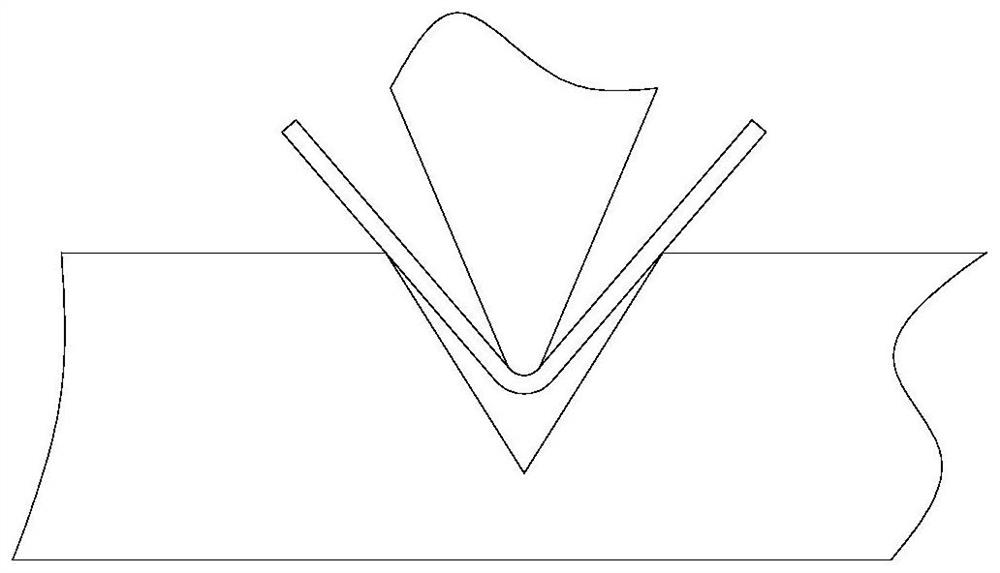

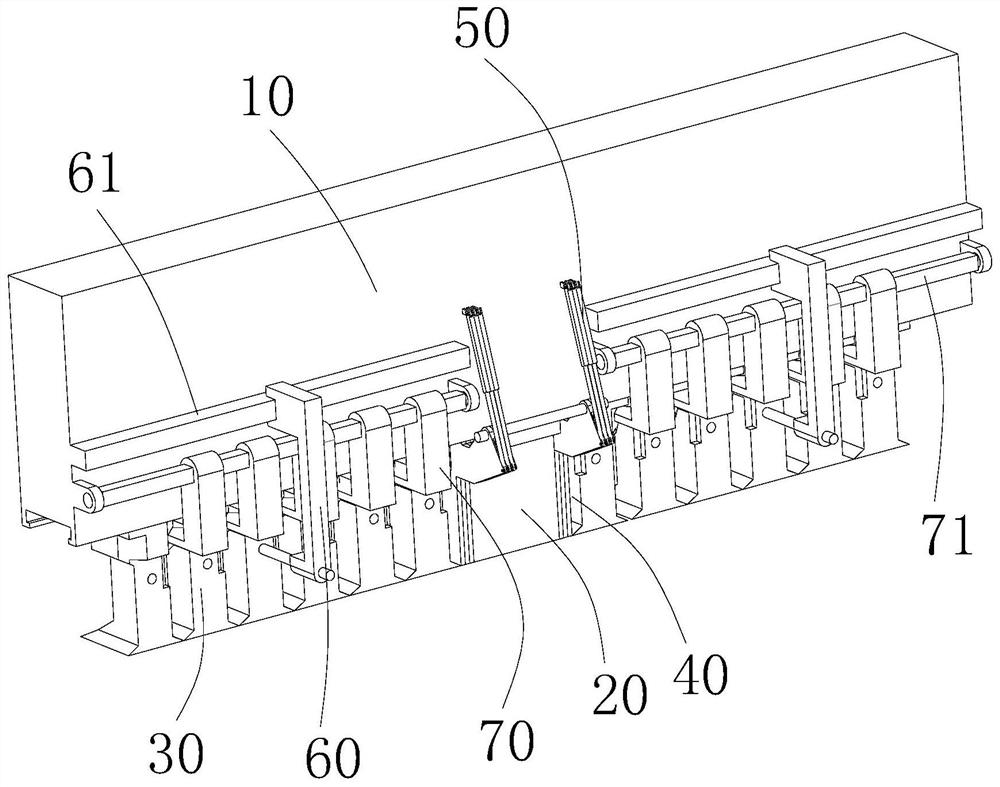

[0116] Such as Figure 17 As shown, the mold distance equidistant mechanism includes a rotating shaft 71, several wedge blocks 73 and equally divided moving arms 72 equal in number to the wedge blocks. A wedge-shaped block is respectively arranged between two adjacent moving molds and between the moving mold and the adjacent adjusting mold.

[0117] Each wedge-shaped block is perpendicular to the length direction of the mold seat, and the inner end of each wedge-shaped block has two guiding slopes 731 arranged symmetrically. The two guide slopes can slide and cooperate with the fixed guide surface and the movable guide surface respectively.

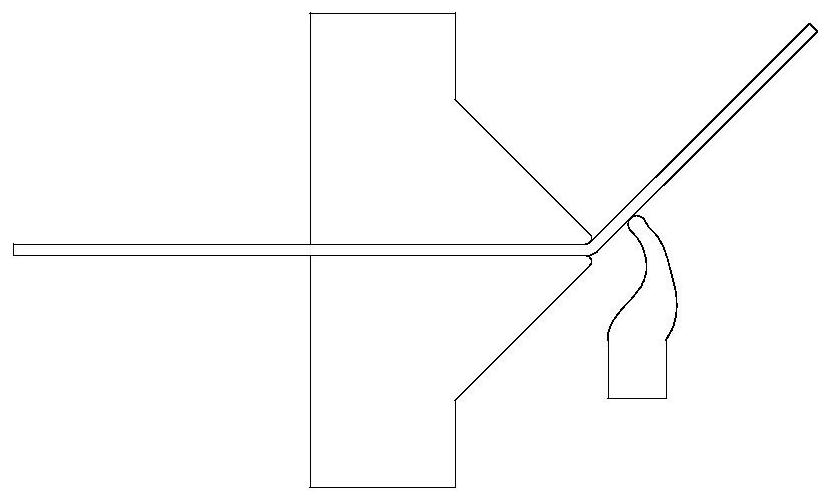

[0118] The rotating shaft is installed on the side wall of the mold seat and is parallel to the length direction of the mold seat, and the rotating shaft can rotate around its own axis under the action of the rotating shaft driving device.

[0119] There can be one or two rotating shafts. In this embodiment, there are preferably two rot...

Embodiment 2

[0126] Such as Figure 20 with Figure 21 As shown, the mold distance equalization mechanism includes several springs, one spring is respectively arranged between two adjacent moving molds and between the moving mold and the adjacent adjusting mold, and each spring is arranged along the length direction of the mold seat.

[0127] The preferred installation method of the spring located between two adjacent movable molds is as follows: the opposite sides of the two adjacent movable molds are preferably provided with spring installation grooves, and the two ends of the spring are respectively located in the spring installation grooves. One end or both ends of the spring are respectively connected with the spring installation groove.

[0128] The installation method of the spring located between the movable mold and the adjacent adjusting mold is as follows: a spring installation groove is arranged in the movable mold facing the adjusting mold, one end of the spring is connected ...

specific example

[0132] Specific example: the width of the fixed mold is 80mm, the width of each movable mold is 100mm, and the width of each adjusting mold is 10mm. When the total length L of the required bending die is 703mm, the selected combination method is: L=80 (fixed die) + 6*100 (movable die) + 2*10 (adjusting die) + 3mm (gap). That is to say, it is necessary to select 6 moving dies and 2 adjusting dies, further, 3 left moving dies, 3 right moving dies, 1 left adjusting die and 1 right adjusting die.

[0133] The mold distance equalizing mechanism in the present invention will make the above-mentioned 3mm gap evenly distributed between each moving mold.

[0134] Step 2, Adjusting mold flipping: According to the number of adjusting molds m selected in step 1, all the remaining unselected adjusting molds far away from the fixed mold are turned upward and lifted away from the mold assembly position through the adjusting mold turning mechanism.

[0135] Step 3, Unlocking the mobile mold:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com