Crank connecting rod mechanism capable of automatic adjustment of length

A crank linkage mechanism and automatic adjustment technology, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that the mechanism cannot obtain the output track, increase the workload of the staff, and the length of the crank rod cannot be adjusted, etc., to achieve a simple structure , easy to make, high practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

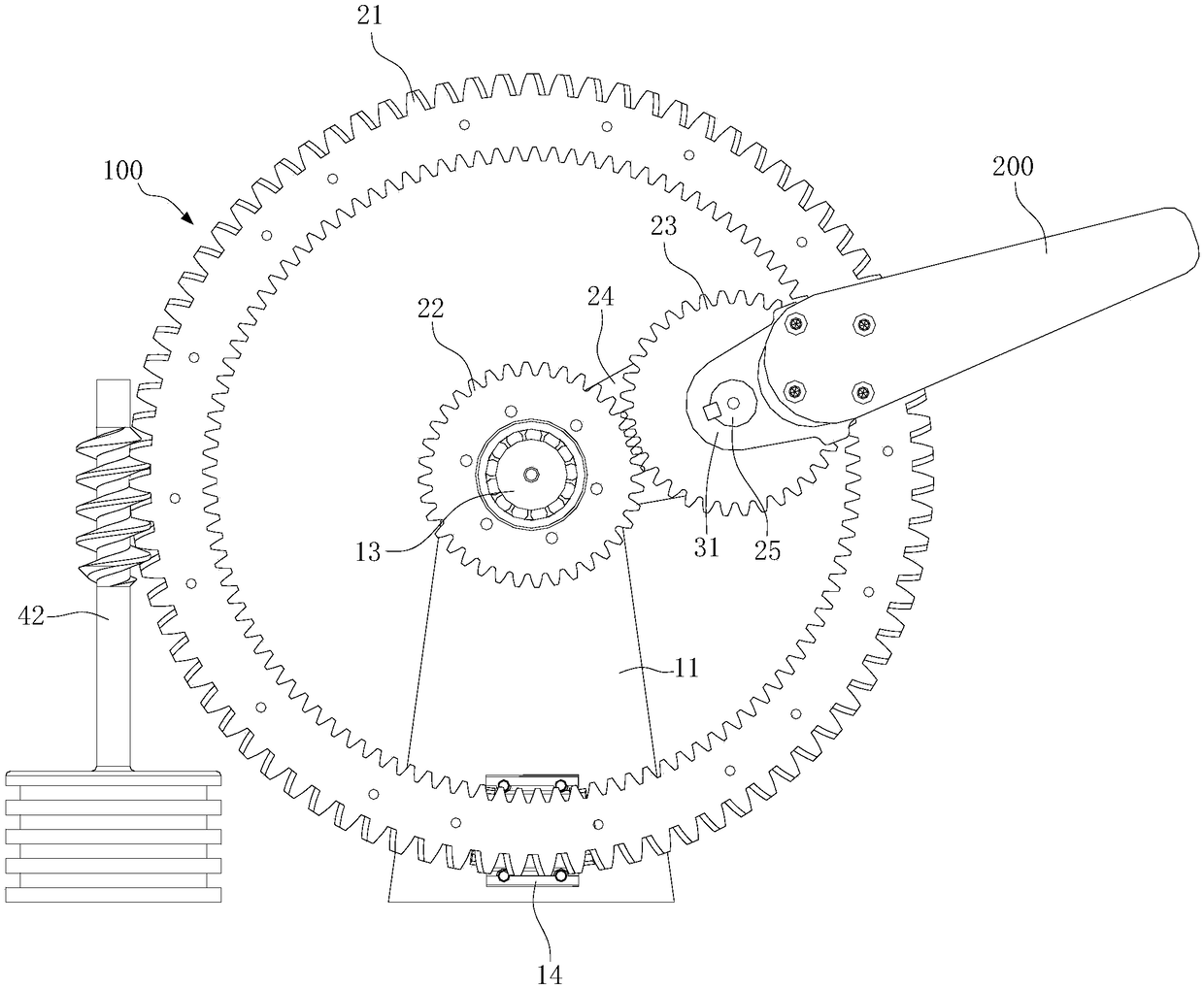

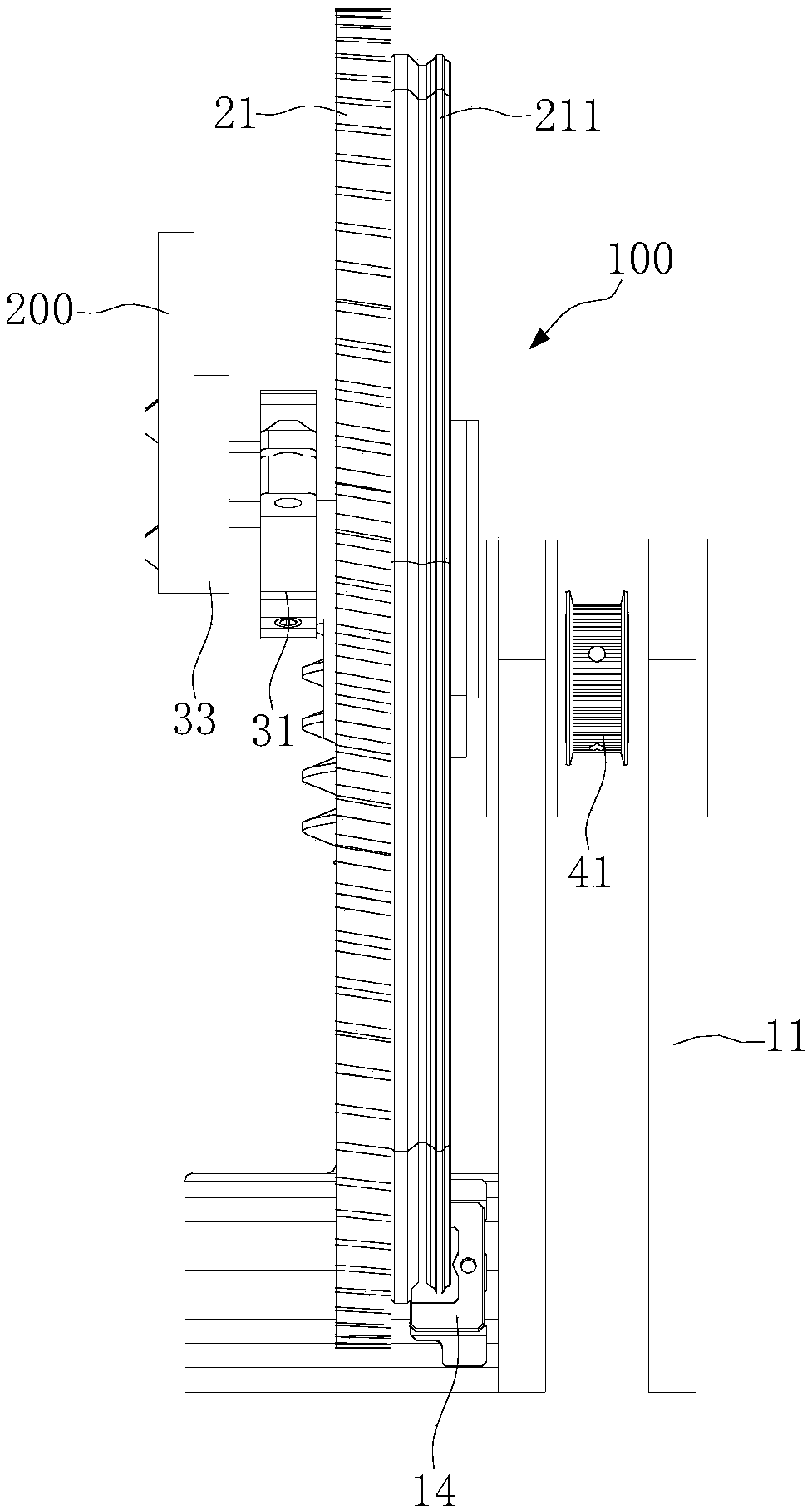

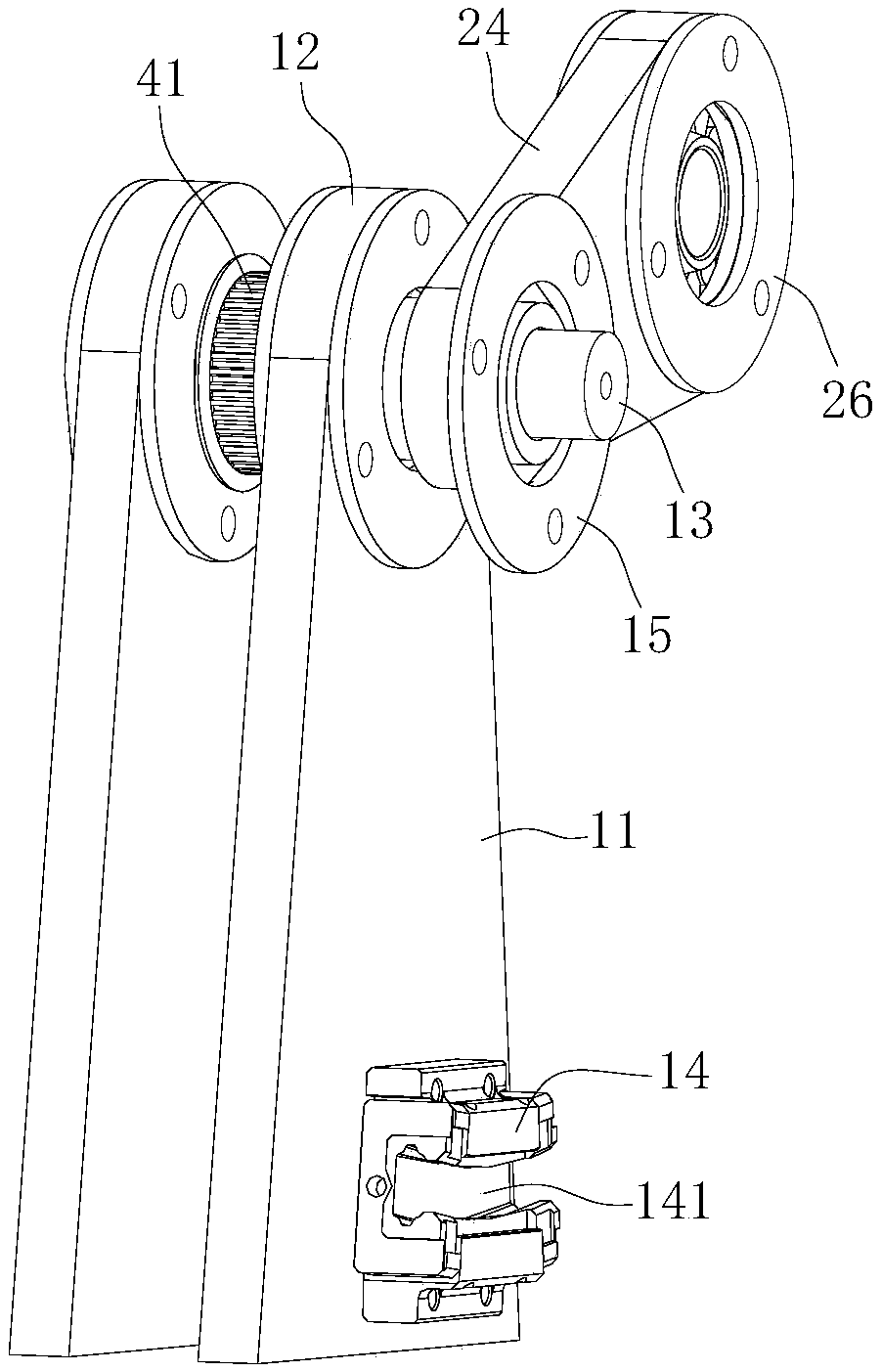

[0030] see below Figure 1 to Figure 7 .

[0031] The automatically adjustable length crank linkage mechanism of the present invention includes a crank rod structure 100 and a connecting rod assembly 200;

[0032] The crank rod structure 100 includes a support unit and a motion unit arranged on the support unit, the motion unit includes a ring gear 21 with internal teeth that is rotatably mounted on the support unit, and a ring gear 21 that is rotatably mounted on the support unit. The planetary carrier 24 on the planetary carrier 24 and the planetary gear 23 with external teeth rotatably mounted on the planetary carrier 24, and the rotation axis of the ring gear 21 and the rotation axis of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com