Speed reduction gear assembly

A reduction gear and assembly technology, applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., can solve the problem of bloated overall structure, and achieve the effect of good deceleration effect, stable force transmission and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

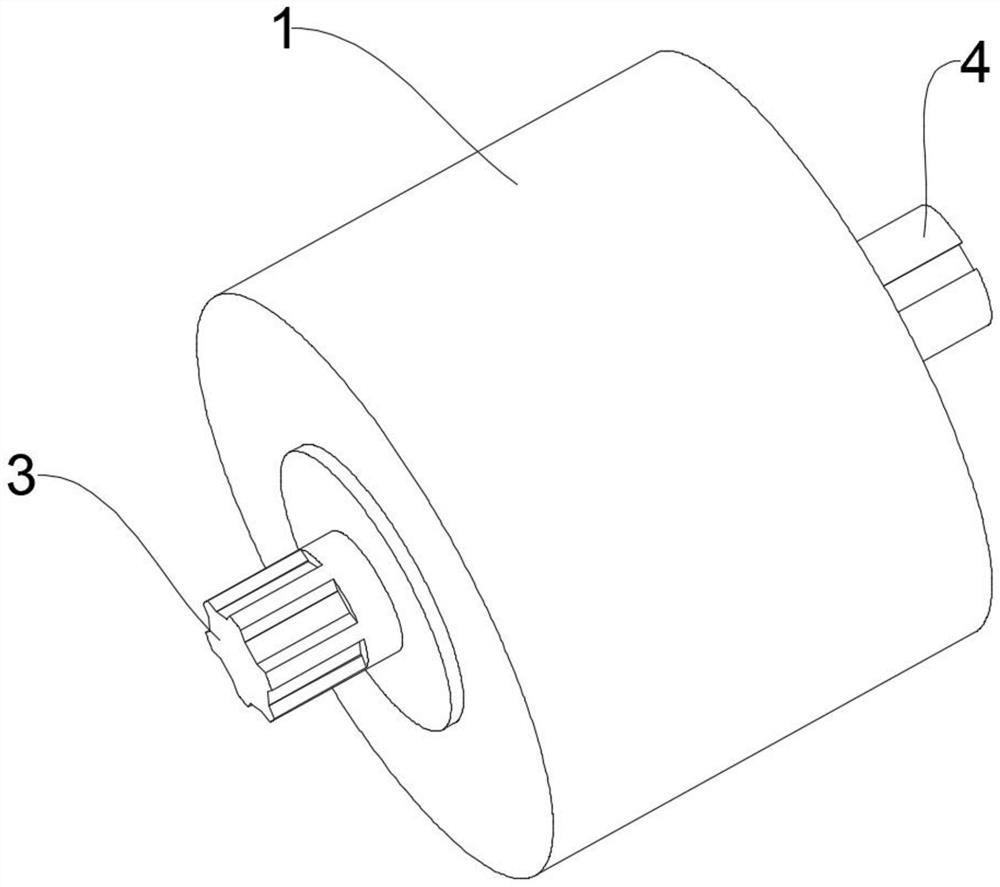

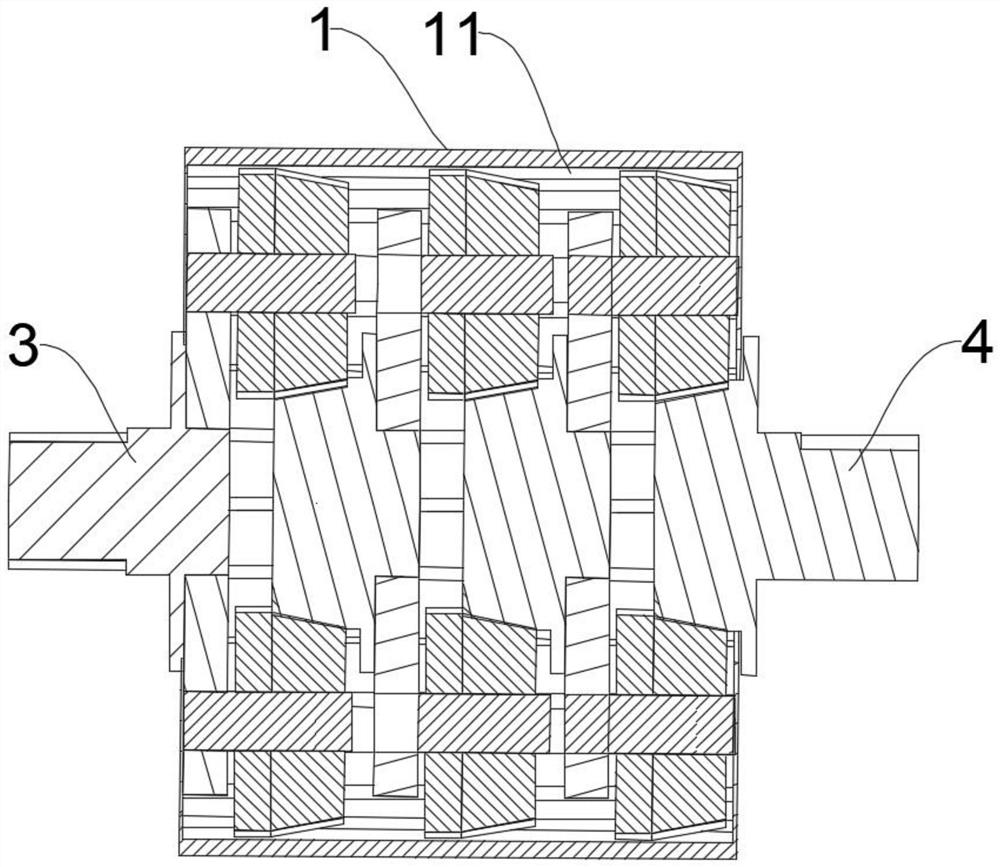

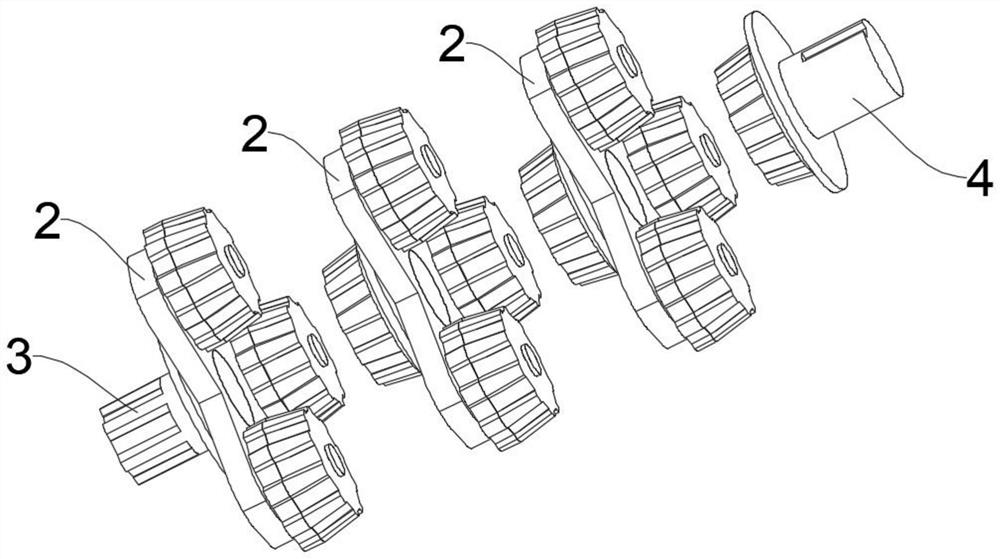

[0029] refer to Figure 1 to Figure 4 As shown in , the reduction gear assembly provided by this embodiment includes:

[0030] The outer shell 1 has an internal gear 11 formed on its inner wall;

[0031] At least one set of planetary gear assemblies 2, each planetary gear assembly 2 includes a planet carrier 21, a rotatable annular array of at least three planet wheels 22 installed on the front end of the planet carrier 21, each planet wheel 22 is formed by a bevel gear connected front and back 25 and spur gears 26, and each spur gear 26 meshes with the internal gear 11 respectively. Except for the planetary gear assembly 2 located at the rearmost side, each other planetary gear assembly 2 also includes a Sun gear 23, the outer circumference of the sun gear 23 has conical gear teeth matching the shape of the bevel gear 25, and each sun gear 23 meshes with the bevel gears 25 of the three planetary gears 22 on the planet carrier 21 at the rear position ;

[0032] The first fu...

Embodiment 2

[0041] refer to Figure 5 As shown in , the structure of the reduction gear assembly provided by this embodiment is basically the same as that of the first embodiment above, the only difference is that the number of planetary gear assemblies 2 in this embodiment is one set, and there is no sun gear 23, The first functional component 3 and the second functional component 4 are directly connected by transmission through the planetary gear assembly 2 .

Embodiment 3

[0043] refer to Figure 5 As shown in , the structure of the reduction gear assembly provided by this embodiment is basically the same as that of the first embodiment above, the only difference is that the number of planetary gear assemblies 2 is arranged in two groups from back to front.

[0044] Apparently, the number of planetary gear assemblies 2 can be determined according to the requirements of practical applications, and is not limited to one to three sets, and can also be set in more sets, and is not limited thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com