High-power brushless electronic water pump

An electronic water pump, high-power technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of small heat dissipation area of the heat sink, difficult installation, and many types of products, and achieves high power, strong magnetism, and low manufacturing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below through specific examples.

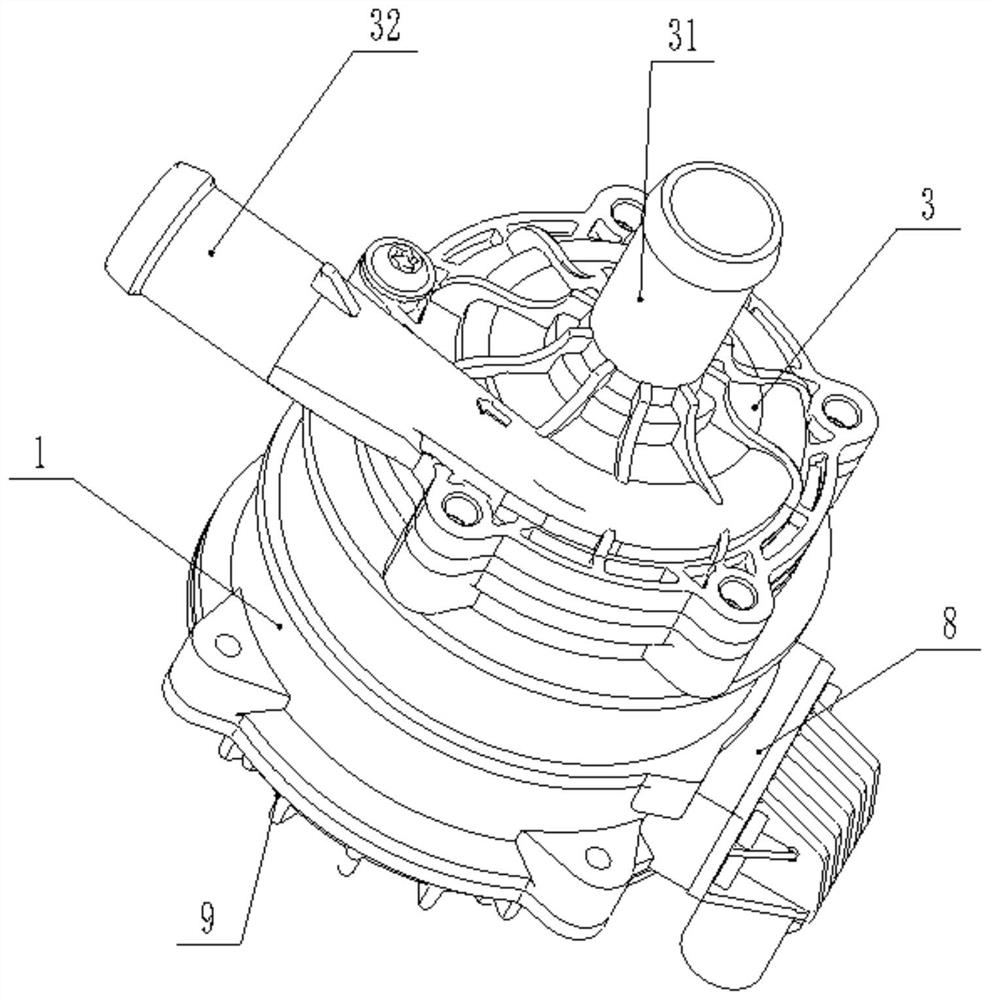

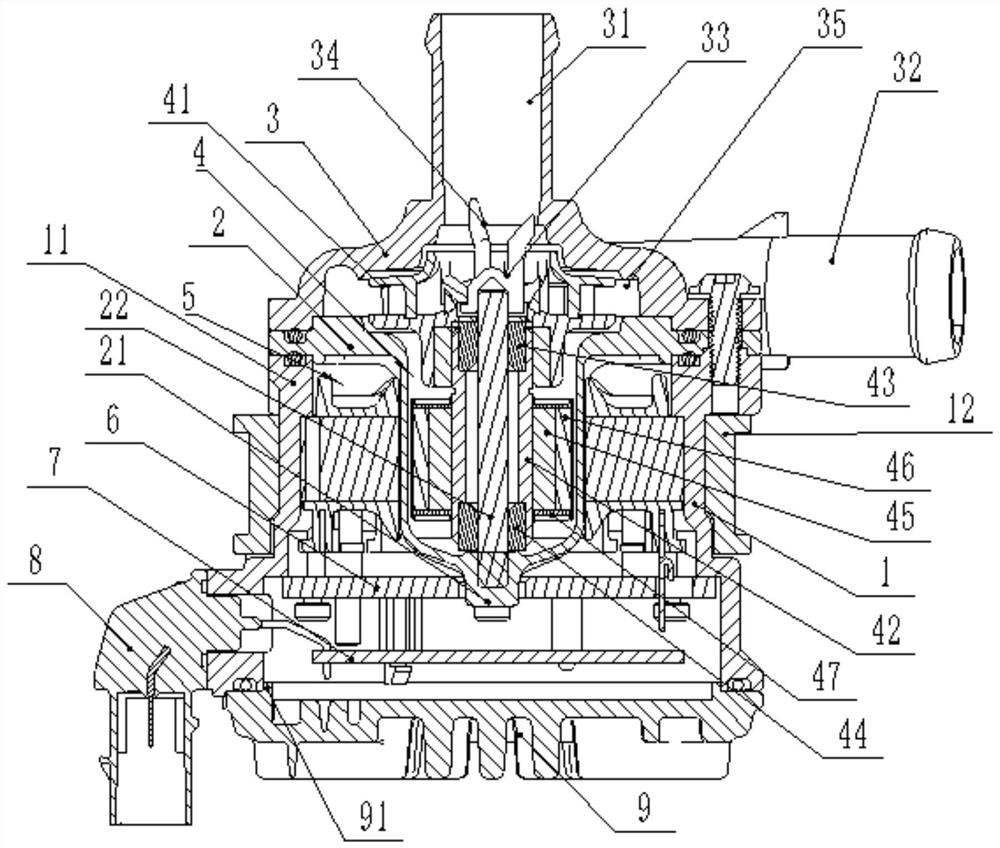

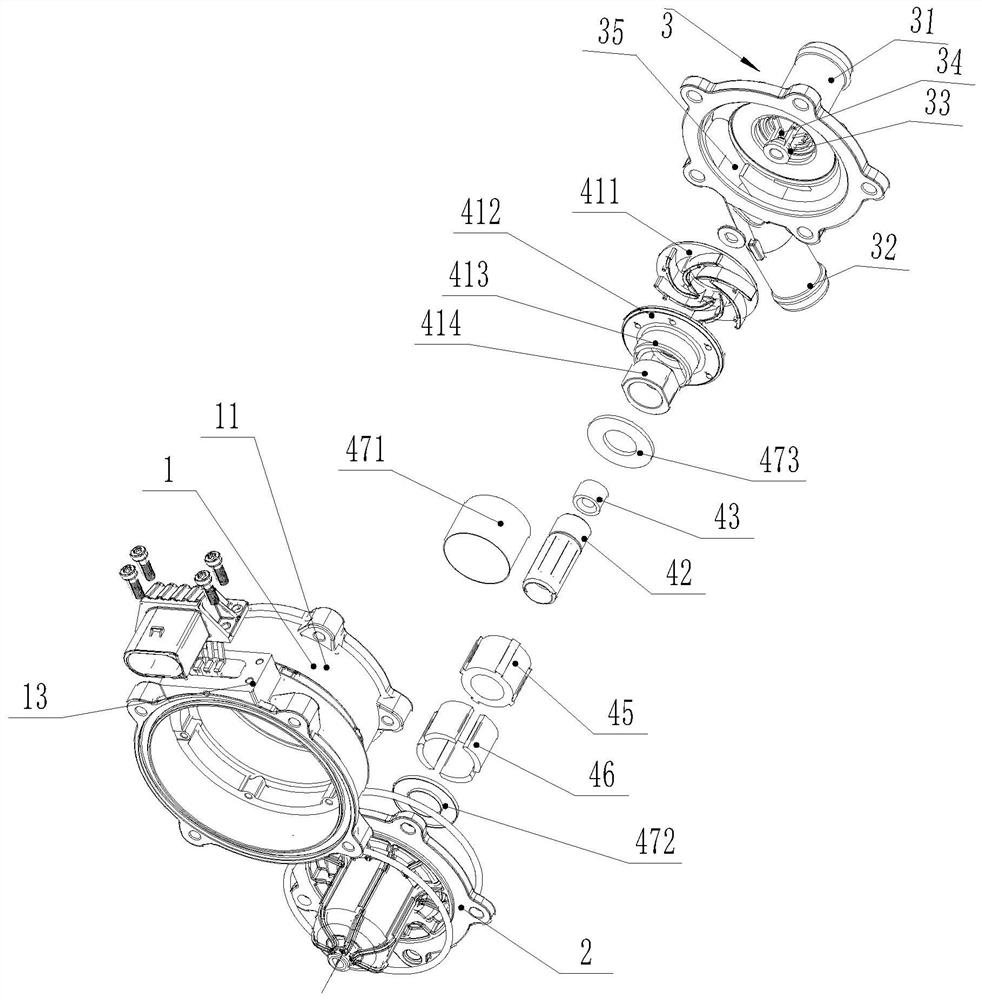

[0041] Such as Figure 1 to Figure 9 As shown, a high-power brushless electronic water pump includes a detachable and fixed shell 1, an insulating sleeve 2 and an upper cover 3, wherein the high power mentioned in the present invention is a relative concept, and is not specific to a certain power. Considering high power, the power of the brushless electronic water pump in the solution of the present invention is greater than that of the brushless electronic water pump mentioned in the background technology. The previous power was 65W, but the current brushless electronic water pump can achieve 110W.

[0042] An installation chamber is formed between the isolation sleeve 2 and the housing 1, a fluid chamber is formed between the isolation sleeve 2 and the upper cover 3, and the fluid chamber and the installation chamber are independent of each other, and the housing 1 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com