Forming assembly for plugging of prefabricated concrete grouting layer as well as component and method

A concrete and prefabricated technology, applied in building construction, construction, building material processing and other directions, can solve the problems of insufficient sleeve grouting fullness, dangerous buildings, hidden dangers of engineering safety, etc., achieve fully qualified construction quality and improve work efficiency. Efficiency, the effect of meeting safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

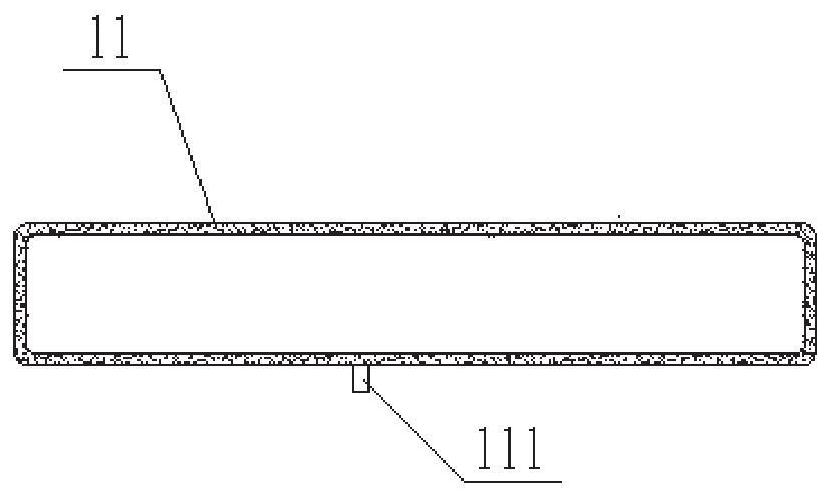

[0032] This embodiment provides a prefabricated concrete grouting layer plugging forming assembly, including a back-shaped or concave-shaped rubber hose surrounding the grouting layer area. The rubber hose can communicate with an external air source to realize inflation and deflation. The rubber hose is set as: In the case of inflation, the grouting layer area is isolated from the outside, and a sealing space is formed outside the hose, which is used to fill the sealing material to form a sealing structure.

[0033] Specifically, an air nozzle 111 is provided on the side wall of the rubber hose 11, and the air nozzle 111 can protrude from the notch. It can be understood that in this solution, the rubber hose adopts an inflatable structure, so that the volume of the rubber hose can be adjusted easily, and when the rubber hose is deflated, it can be easily pulled out from the sealing structure formed by the sealing slurry.

[0034] In this embodiment, the back-shaped rubber hose...

Embodiment 2

[0036] This embodiment provides a plugging method for the assembled concrete grouting layer 8, comprising the following steps:

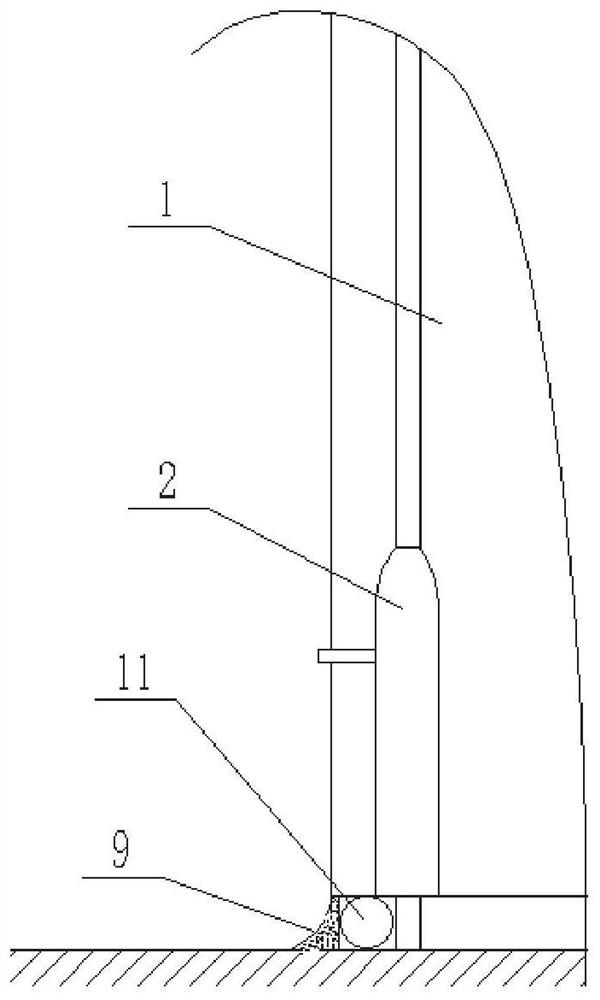

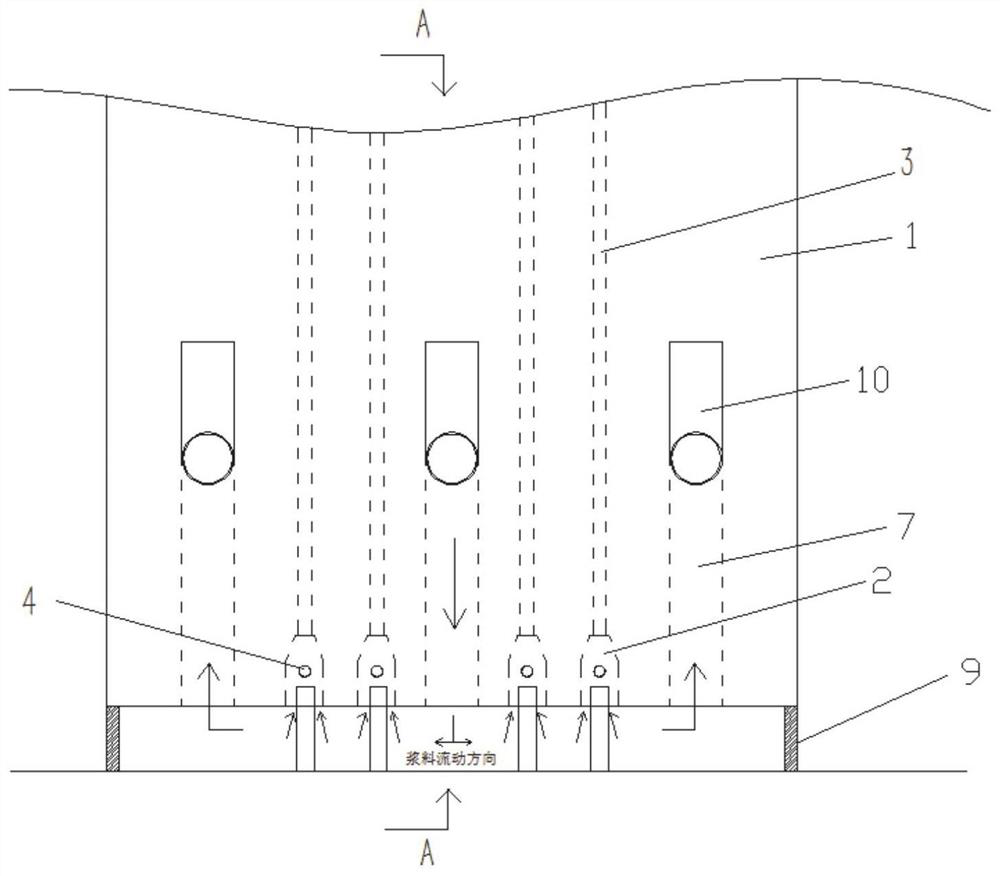

[0037] In step 1, the wall panel 1 is placed on the upper surface of the floor slab, and the steel bar 3 in the floor slab is inserted into the cylinder 2 in the wall panel 1 .

[0038] In step 2, a gap is reserved between the lower surface of the wall panel 1 and the upper surface of the floor slab to facilitate the pouring of the grouting layer 8; specifically, a spacer is provided between the lower surface of the wall panel 1 and the upper surface of the floor slab to form a gap , The pad and the poured grout in the grout layer 8 form an integral structure.

[0039] Step 3, arrange a rubber hose 11 around the area where the grouting layer 8 is located, and inflate the rubber hose 11 so that the lower opening of the cylinder body 2 is isolated from the external environment.

[0040] Step 4, filling the sealing material in the sealing space outside...

Embodiment 3

[0044] This embodiment provides a prefabricated concrete component. The wall panel 1 is arranged above the floor, and the sealing structure 9 described in Embodiment 1 is arranged between the wall panel 1 and the floor. The sealing structure 9 encloses a pouring space. The grouting layer 8 formed by pouring in the pouring space is used for bonding the wall panel 1 and the floor slab.

[0045] A grouting pipe 6 is provided in the wallboard 1, and the opening at the lower end of the grouting pipe 6 passes through the lower end surface of the wallboard 1 and communicates with the space where the grouting layer 8 is located; the opening at the upper end of the grouting pipe 6 passes through the side of the wallboard 1, And can communicate with external grouting equipment.

[0046] Specifically, an indicator tube 7 is pre-embedded in the wall panel 1, and the opening at the lower end of the indicator tube 7 passes through the lower end surface of the wall panel 1 and communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com