Vibrating automatic precast prestressed concrete stair mold and making method

A stair mould, concrete technology, applied in the direction of moulds, manufacturing tools, supply devices, etc., can solve the problems of stair cracking, anchorage loosening, prestressed steel wire stress loss, etc., to improve flatness, avoid displacement, and avoid prestressing loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

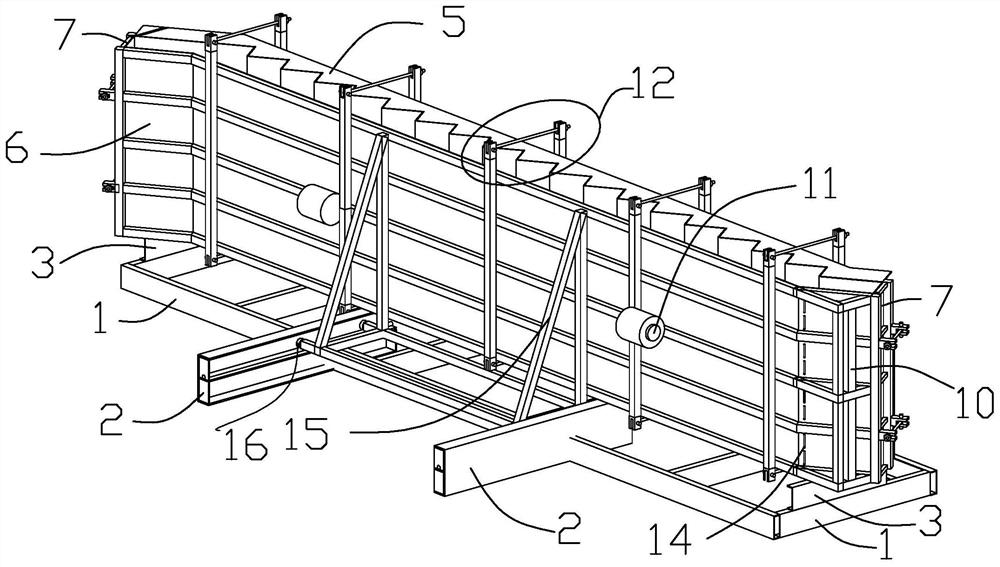

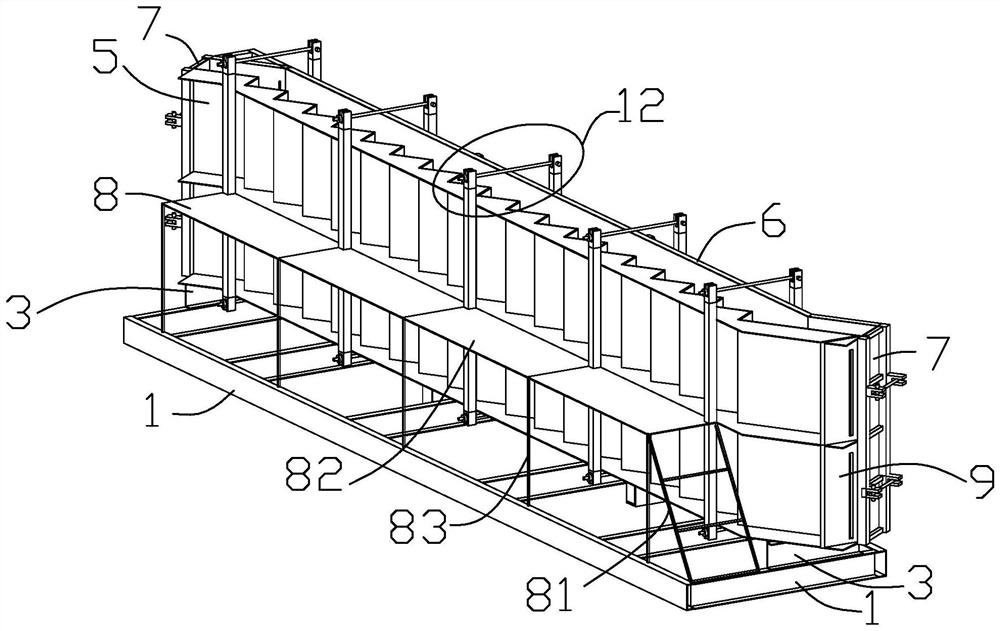

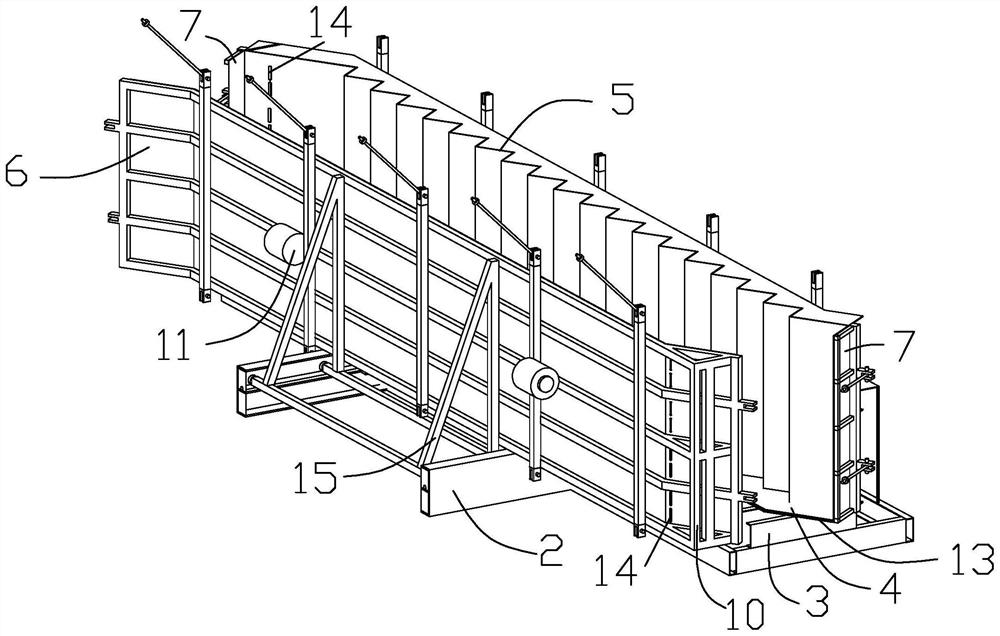

[0036] Refer to the attached figure 1 to attach Figure 5 A vibration automatic prefabricated prestressed concrete staircase mold and its manufacturing method of the present invention will be described in detail below.

[0037] A vibrating automatic prefabricated prestressed concrete staircase mold of the present invention has a structure comprising a base 1, a sliding track 2, a supporting channel steel 3, a bottom mold 4, a fixed side mold 5, a movable side mold 6, an end mold 7, and an operating platform 8. Fixed bracket 9, tension bracket 10, high-frequency vibration motor 11, puller 12, sealing rubber strip 13, long hole 14, triangular support frame 15 and roller 16.

[0038] The base 1 is made of channel steel or square steel criss-cross welded, which is used to support the entire upper structure and transmit the mold and internal concrete weight to the ground. The base 1 is welded with two slide rails 2 along the lengthwise three-point position. The slide rails are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com