Reaction kettle, reaction system and reaction method

A reaction system and reactor technology, applied in the chemical industry, can solve problems such as too late condensation, too much solvent volatilization, and product explosion, so as to reduce the possibility of explosion, reduce condensation load, and improve consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

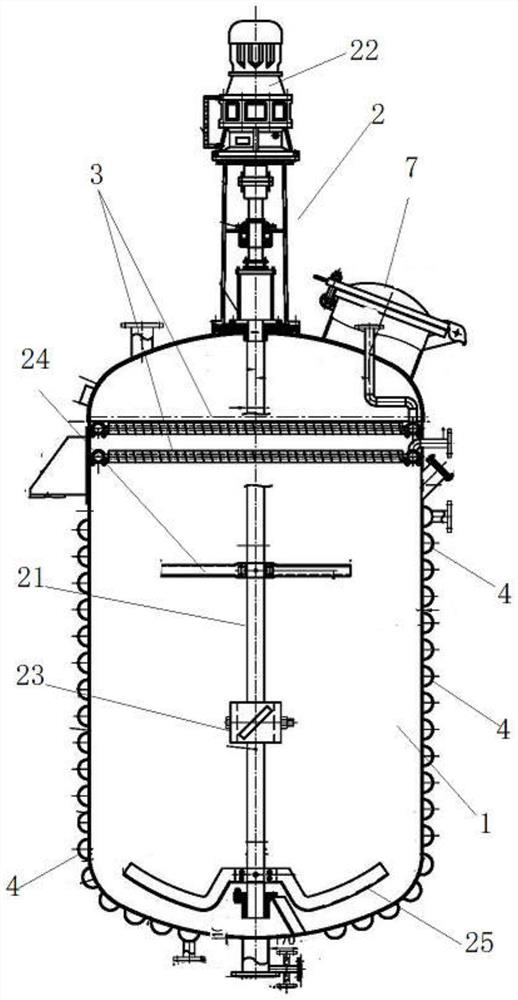

[0042] see Figure 1~5 , a reaction kettle, comprising a kettle body 1 and an agitator 2 extending into the kettle body 1, the upper part of the inner cavity of the kettle body 1 is provided with a cooling layer;

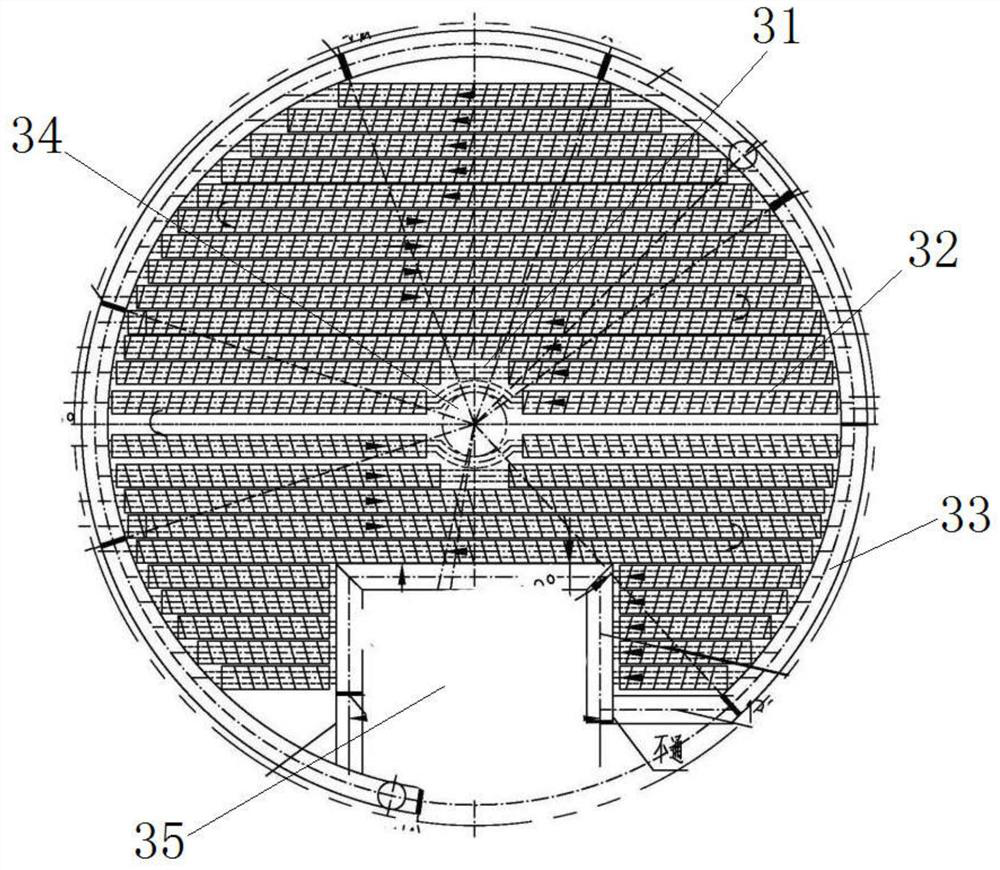

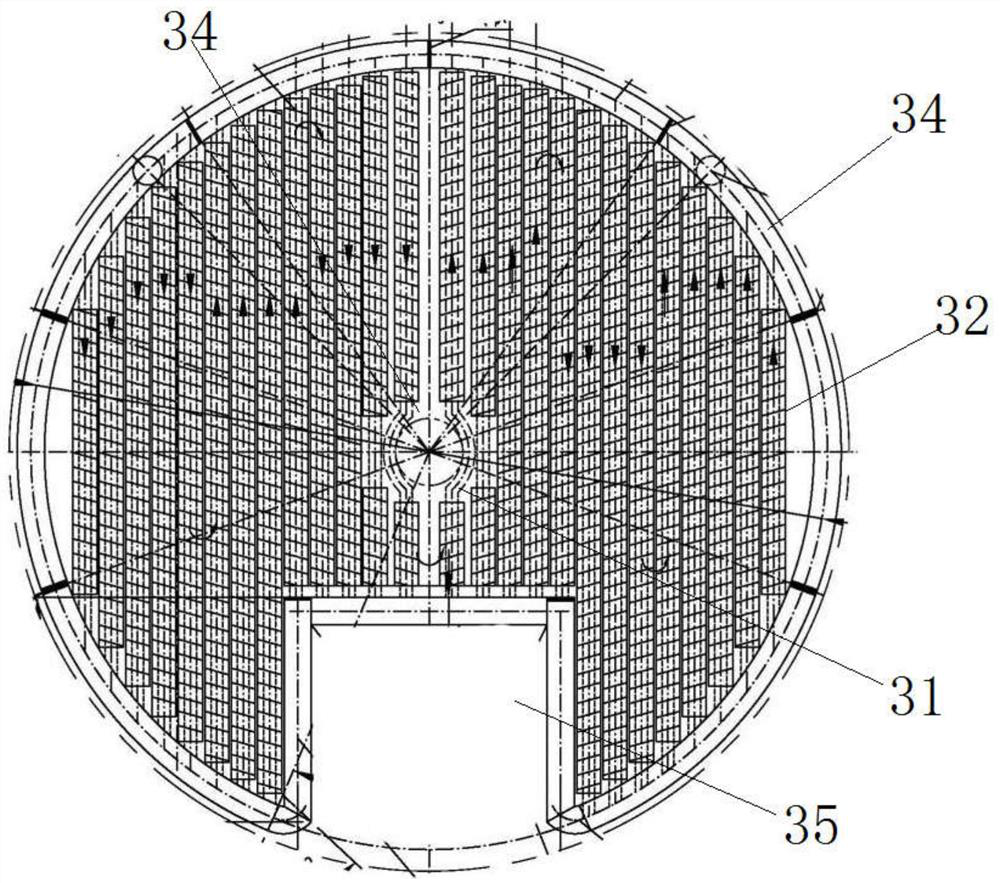

[0043] The cooling layer is at least one fin layer 3;

[0044] The fin layer 3 is composed of a plurality of cooling tubes 31 arranged side by side, and the cooling tubes 31 are provided with fins 32 .

[0045] In practical applications, the fin layer 3 can be 1 layer, 2 layers or 3 layers; the refrigerant, such as supercooled brine, is passed into the cooling pipe 31, and the fins 32 are mainly used to transfer the heat of the solvent vapor and the heat in the cooling pipe 31. The heat of the refrigerant is exchanged. The fins 32 extend along the length direction of the cooling tube 31 .

[0046] As a further improvement, an inert gas supply pipe is provided at the bottom of the still body. During the reaction, nitrogen is supplied through the inert gas supply p...

Embodiment 2

[0064] refer to Figure 6 , a reaction system, comprising a stirred tank as described in embodiment 1 and a cooler externally connected to the reactor, the cooler is a horizontal condenser 6, and the inlet of the horizontal condenser communicates with the reactor , the outlet of the horizontal condenser is connected with a liquid storage tank 5, and a reflux pump is arranged between the liquid storage tank 5 and the reactor; the liquid storage tank or the horizontal condenser or the liquid storage tank and the horizontal condenser There is a vent opening connected to the atmosphere between the devices to release non-condensable gas.

[0065] Through the combination of the external condenser and the fin layer 3, the solvent vapor can be condensed more favorably, and at the same time, the significant change of the solvent content in the system caused by the temperature fluctuation can be reduced, so that the reaction is more stable and controllable.

[0066] Application Test 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com