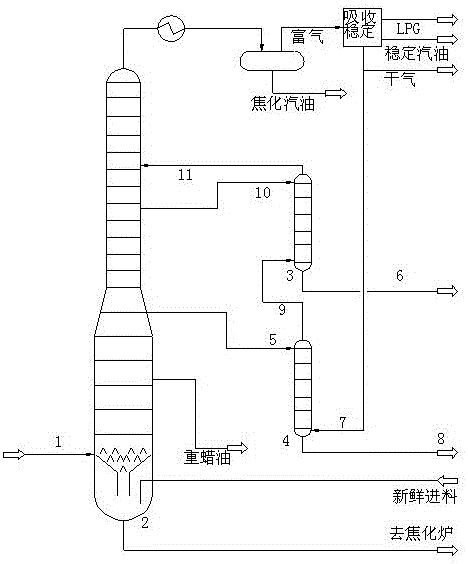

A process for increasing the production of coked diesel oil

A process method and technology for coking diesel oil, which are applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil processing products, etc., can solve the problems of increasing the load of the coking main fractionation tower, increasing the unit cost of recovering diesel oil, increasing the tower top condensation cooling load, etc. Achieve the effect of reducing the flow of acidic sewage, saving energy and reducing consumption, and increasing the economic benefits of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The method of the present invention is used in a certain 2 million tons / year delayed coking unit.

[0045] A stripper is installed in the side line production of coking wax oil, and the properties of coking wax oil recovered by steaming in advance are shown in Table 1. The stripping operation is carried out using coke dry gas. The composition of coking dry gas is shown in Table 2. The diesel fraction in the coker wax oil is recovered by stripping operation, so that the initial boiling point of the coker wax oil reaches 311°C, and the yield of the coker wax oil is calculated as 20% of the raw material. The simulation calculation results are shown in Table 3.

Embodiment 2

[0062] The method of the present invention is used in a certain 2 million tons / year delayed coking unit.

[0063] A light gas oil stripper is installed in the side line production of coking gas oil, and the properties of coking gas oil recovered by steam ahead of time are shown in Table 1. The stripping operation is carried out using coke dry gas. The composition of coking dry gas is shown in Table 2. The properties of the light fraction at the top of the wax oil stripper are shown in Table 4. The light fraction at the top of the wax oil stripper enters the diesel stripper, and the properties of the diesel fraction recovered from the bottom of the diesel stripper are shown in Table 4. The diesel fraction in the coker wax oil is recovered by stripping operation, so that the initial boiling point of the coker wax oil reaches 311°C, and the yield of the coker wax oil is calculated as 20% of the raw material. The simulation calculation results are shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com