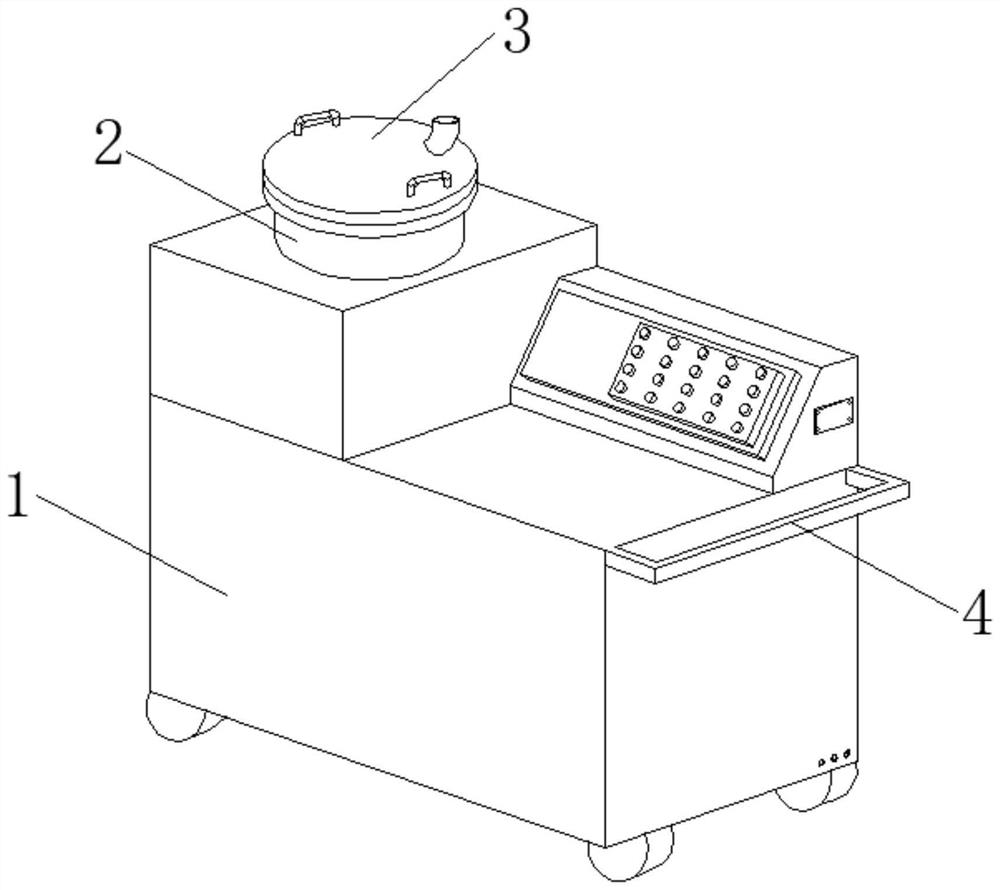

Mixing device for automatic powder batching system

A mixing device and automatic batching technology, which is applied in the direction of solid-solid mixing, mixers, mixing methods, etc., can solve problems that are easy to cause accidents, achieve the effects of avoiding collisions, improving comfort, and reducing extrusion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

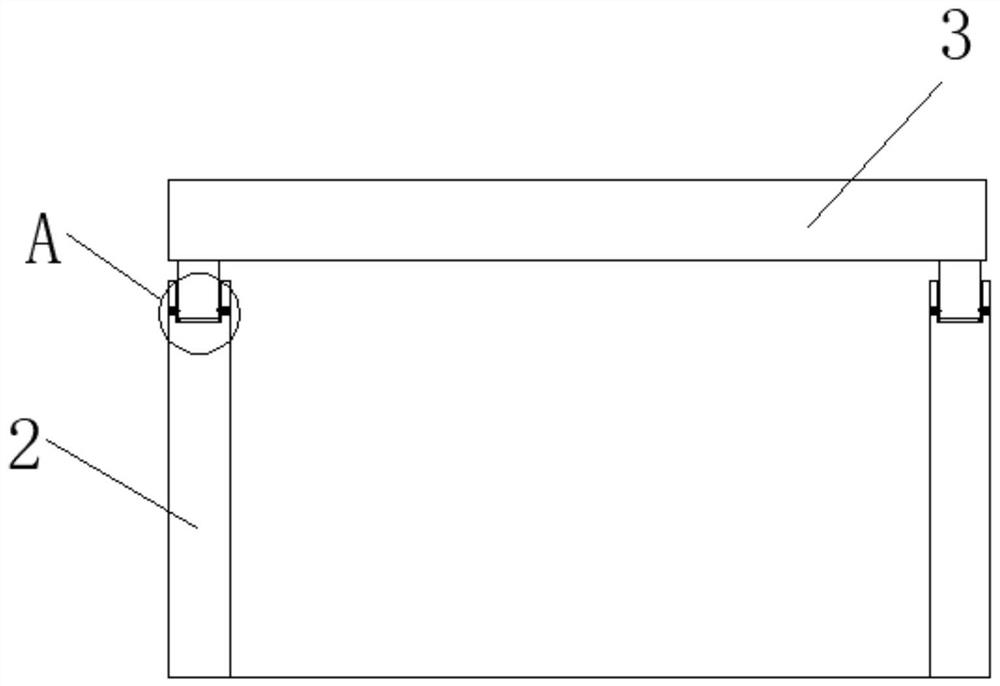

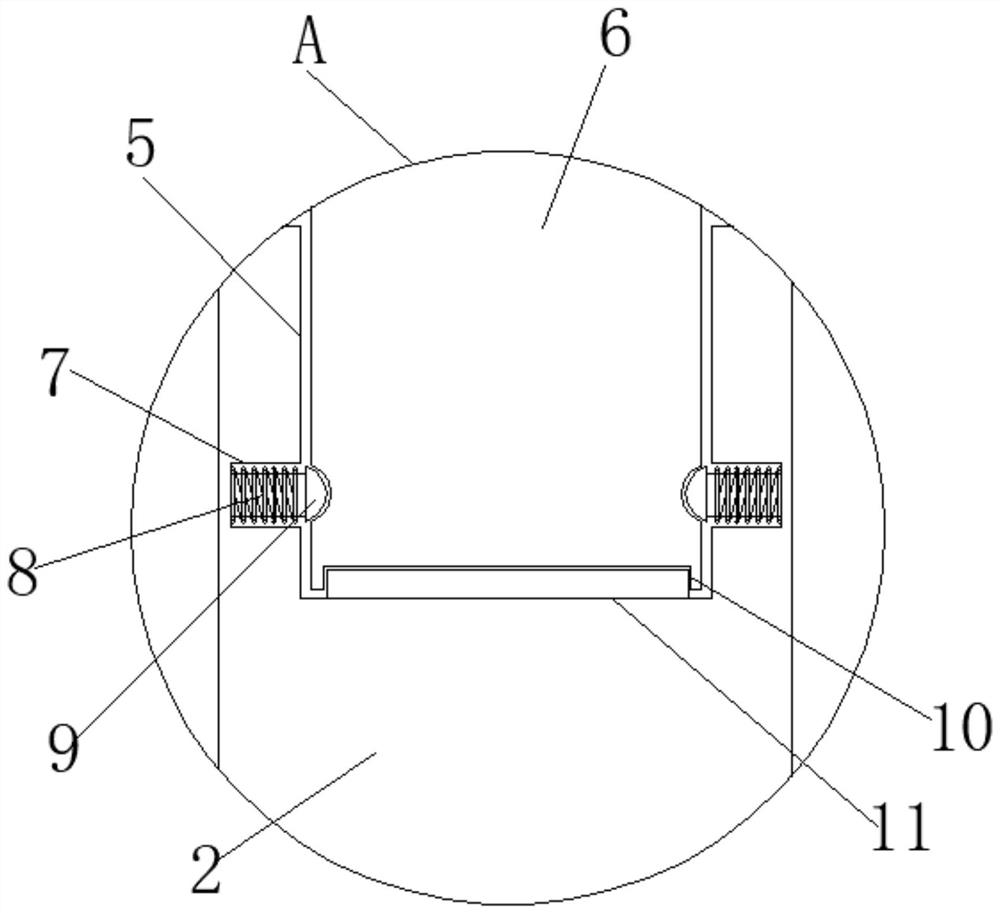

[0021] As an embodiment of the present invention, a mounting block 15 is symmetrically installed on the side surface of the mixing device main body 1, and a rotating column 16 is installed through the inside of the mounting block 15, and a mounting groove 14 is symmetrically opened on the inner wall of the handle 4, and the rotating column 16 The end of the mounting block 15 is limitedly engaged with the mounting groove 14, and one end of the mounting block 15 is provided with a fixing bolt 17 penetrating to the surface of the rotating column 16, and the fixing bolt 17 and the rotating column 16 are extruded and fitted.

[0022] As an embodiment of the present invention, a fixing groove 12 is provided inside the handle 4, and a rubber pad B13 is arranged inside the fixing groove 12, and the thickness of the rubber pad B13 is one centimeter.

[0023] As an embodiment of the present invention, the surface of the limiting head 9 is arc-shaped, and the diameter of the limiting head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com