Vehicle power supply

A power supply, power supply technology, applied in electrical components, vehicle components, circuits or fluid pipelines, etc., can solve the problems of difficult heat dissipation, power supply damage, power supply temperature rise, etc., to improve heat dissipation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

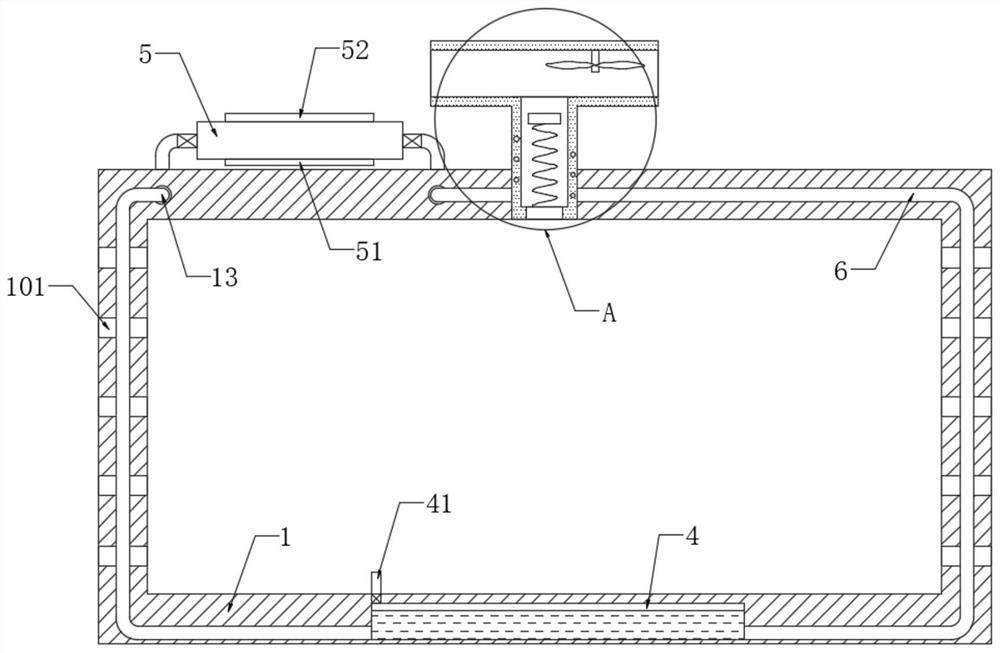

[0019] refer to Figure 1-2 , a vehicle power supply, comprising a supply housing 1, a power supply device is installed in the supply housing 1, the side wall of the supply housing 1 is provided with cooling holes 101, and the supply housing 1 is fixedly connected with The exhaust pipe 3 communicating with the inside thereof, the side wall of the exhaust pipe 3 is fixedly connected with the windward pipe 2 communicating with the inside thereof.

[0020] A liquid storage tank 4 is opened on the inner wall of the supplier housing 1, and the liquid storage tank 4 is filled with cooling liquid. The inner top of the liquid storage tank 4 is provided with an air intake pipe 41. It should be noted that the air intake pipe 41 can make the cooling liquid When flowing into or out of the liquid storage tank 4, the air can be discharged from the liquid storage tank 4 or flow into the liquid storage tank 4 for replenishment, so that the cooling liquid can flow smoothly. In addition, the ai...

Embodiment 2

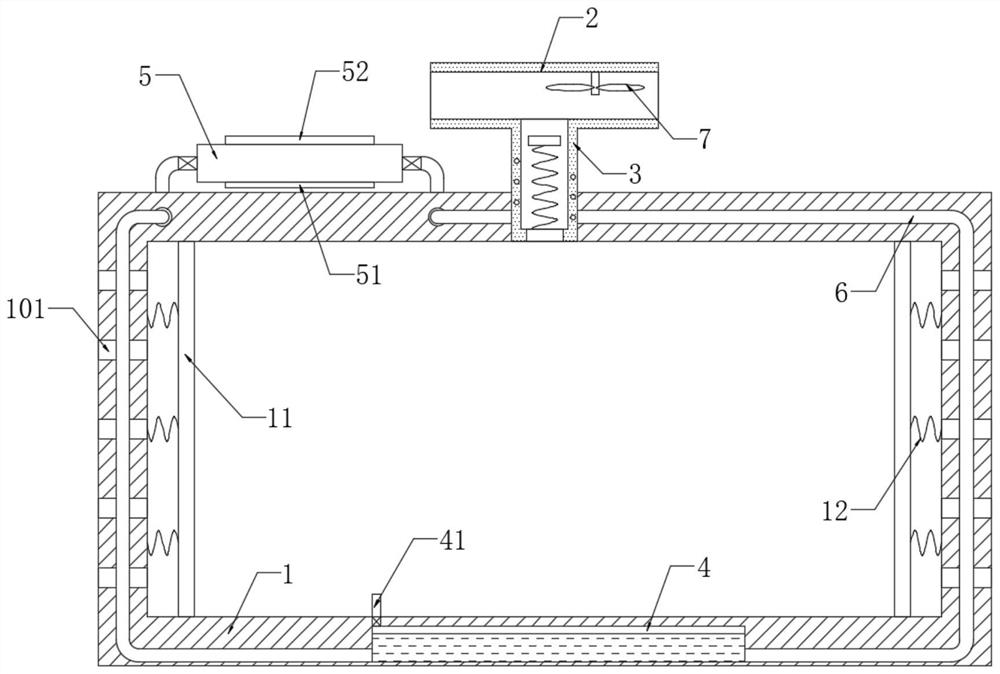

[0025] refer to image 3 , different from Embodiment 1, the supplier housing 1 is embedded with a dust filter 11, and the dust filter 11 is elastically connected to the inner wall of the supplier housing 1 through the second spring 12, and the second spring 12 and the spiral The coil 10 is coupled.

[0026] Due to the dust raised by the vehicle during driving, the dust will inevitably enter the interior of the power supply and gradually accumulate on the various electronic components in the power supply device, resulting in a decrease in the heat dissipation efficiency of the power supply. Therefore, this implementation can effectively prevent dust from falling on the power supply equipment in the supplier housing 1 by setting the dust filter 11, and at the same time, the induced current generated intermittently in the helical coil 10 is also constantly leading to the second spring 12, and the second spring 12 It shrinks when the power is turned on, and stretches and recovers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com