Lead storage battery repairing agent and repairing method

A lead-acid battery and repair agent technology, applied in lead-acid battery, secondary battery repair/maintenance, secondary battery and other directions, can solve the problems of affecting battery capacity and life, reducing lead battery capacity, and unsatisfactory repair effect, etc. Improve the battery capacity repair rate, reduce water loss, and improve the effect of capacity repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

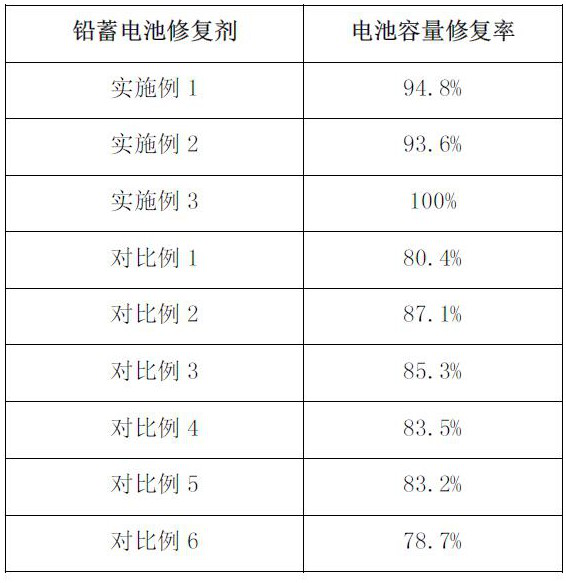

Examples

Embodiment 1

[0020] The lead storage battery restoration agent comprises the following raw materials in parts by weight: 10 parts of ammonium acetate, 0.1 part of graphene, 2 parts of mercaptoethanol, 8 parts of ferrous sulfate, 3 parts of disodium edetate, 0.01 part of gellan gum, sulfuric acid 5 parts of copper and 45 parts of sulfuric acid solution with a mass concentration of 15%.

[0021] Prepare according to the following method: (1) Add gellan gum to the sulfuric acid solution and stir evenly; (2) Add gellan gum to step (1)

[0022] Add ammonium acetate, edetate disodium and copper sulfate to the obtained mixed solution, and disperse by ultrasonic for 10 minutes; (3) Add graphene, mercaptoethanol and ferrous sulfate to the mixed solution obtained in step (2) and mix evenly to obtain Lead battery repair agent.

Embodiment 2

[0024] The lead storage battery restoration agent comprises the following raw materials in parts by weight: 15 parts of ammonium acetate, 3 parts of graphene, 5 parts of mercaptoethanol, 10 parts of ferrous sulfate, 8 parts of disodium edetate, 0.05 part of gellan gum, sulfuric acid 1 part of copper and 20 parts of sulfuric acid solution with a mass concentration of 25%.

[0025] Prepare according to the following method: (1) Add gellan gum to the sulfuric acid solution and stir evenly; (2) Add gellan gum to step (1)

[0026] Add ammonium acetate, disodium edetate and copper sulfate to the resulting mixed solution, and disperse by ultrasonic for 20 minutes; (3) Add graphene, mercaptoethanol and ferrous sulfate to the mixed solution obtained in step (2) and mix evenly to obtain Lead battery repair agent.

Embodiment 3

[0028] The lead storage battery restoration agent comprises the following raw materials in parts by weight: 12 parts of ammonium acetate, 0.5 part of graphene, 3 parts of mercaptoethanol, 5 parts of ferrous sulfate, 5 parts of disodium edetate, 0.02 part of gellan gum, sulfuric acid 3 parts of copper and 40 parts of sulfuric acid solution with a mass concentration of 20%.

[0029] Prepare according to the following method: (1) Add gellan gum to the sulfuric acid solution and stir evenly; (2) Add gellan gum to step (1)

[0030] Add ammonium acetate, disodium edetate and copper sulfate to the obtained mixed solution, and disperse by ultrasonic for 30 minutes; (3) Add graphene, mercaptoethanol and ferrous sulfate to the mixed solution obtained in step (2) and mix evenly to obtain Lead battery repair agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com