SiOx@C-CNT-G composite negative electrode material, preparation method and lithium ion battery

A negative electrode material and composite material technology, which is applied in the field of SiOx@C-CNT-G composite negative electrode material and preparation, can solve the problems of low conductivity, poor performance, and decreased cycle performance of silicon-based composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing the SiOx@C-CNT-G composite negative electrode material according to any one of claims 1 to 4, comprising the following steps:

[0056] A) SiOx particles, dispersant, additive and graphene slurry are mixed, dried and granulated to obtain a SiOx-G precursor;

[0057] B) under a protective gas atmosphere, heat the SiOx-G precursor to 450-650°C, stop feeding the protective gas, and feed the first carbon source gas for reaction to obtain a SiOx@C-G material;

[0058] C) stop feeding the first carbon source gas, feed a protective gas, heat the SiOx@C-G material to 700-1000°C, stop feeding the protective gas, feed the second carbon source gas, and carry out the original By growing carbon nanotubes in place, SiOx@C-CNT-G composite anode materials were obtained.

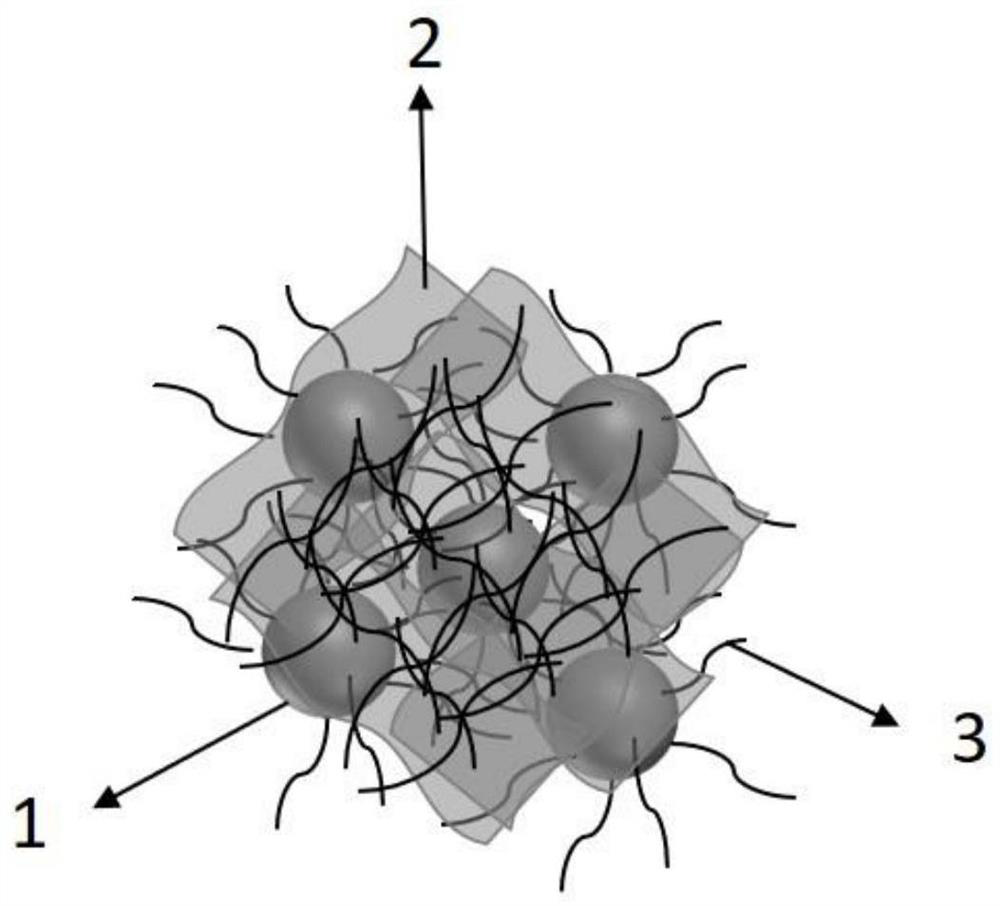

[0059] In the present invention, SiO is obtained by compounding silicon-based materials with graphene and then performing gas-phase coating, and graphene cata...

Embodiment 1

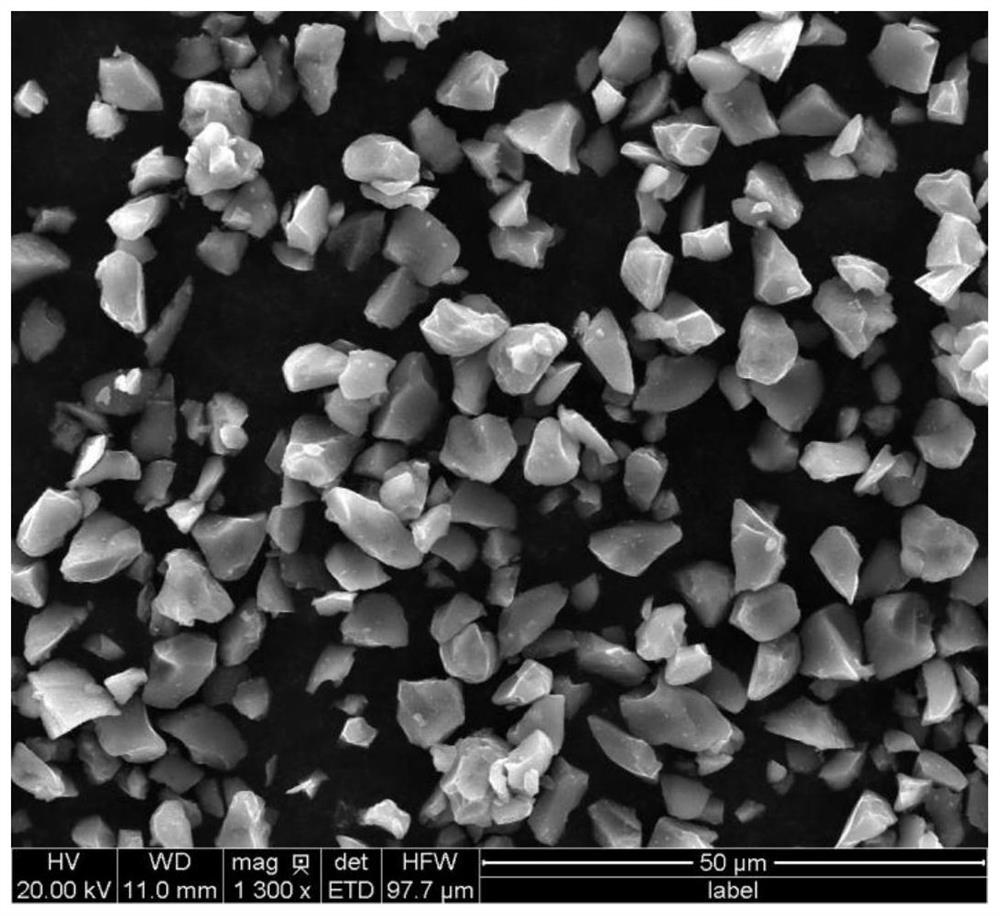

[0081] SiO xCoarse particles are pulverized in a pulverizer, the speed of the pulverizer is 1600 rpm, pulverized and pulverized in the jet pulverizer for 0.5h, and then pulverized in the jet pulverizer, the jet pulverizer classifier is 1800 rpm min; the gas flow pressure is preferably 0.8MPa, and the obtained SiO with a particle size of 1 μm to 7 μm x precursor.

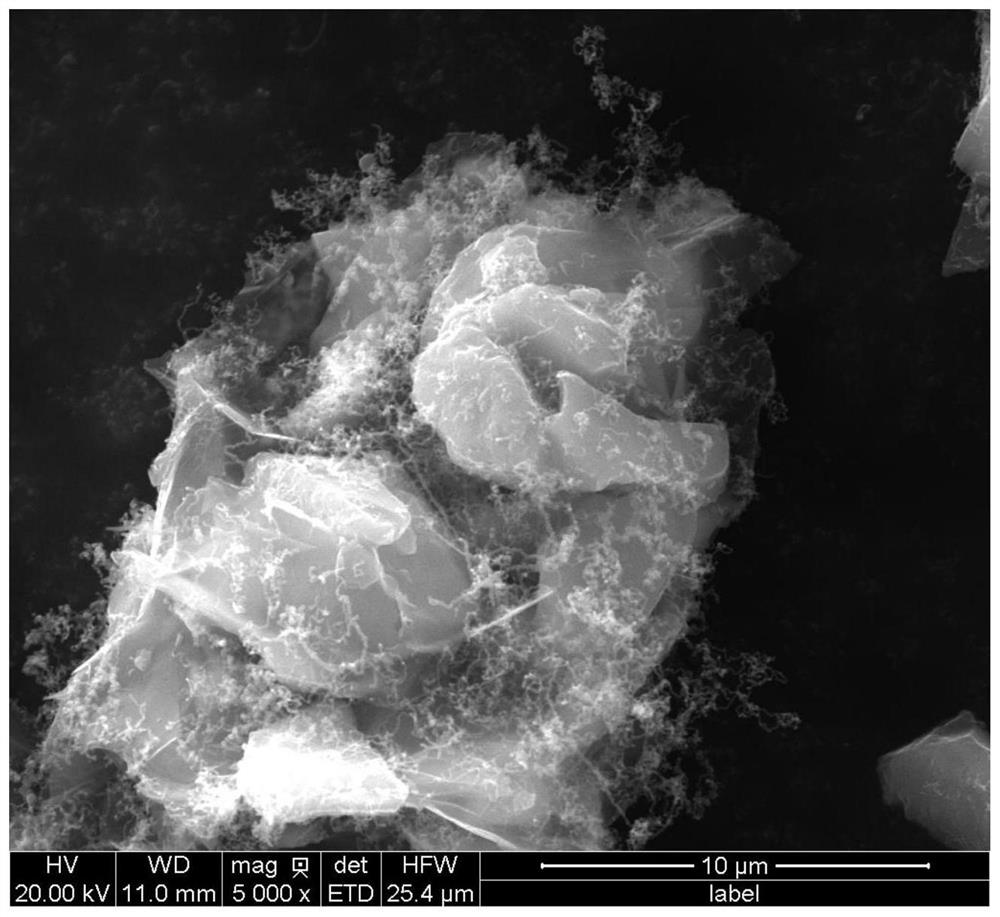

[0082] 2kgSiO x The precursor, 100g dispersant, 100g additive, and 20kg graphene slurry were mixed evenly and then spray-dried for granulation. The temperature of the drying air inlet was 220°C, and the temperature of the air outlet was 90°C. The obtained SiOx-G precursor was placed in the atmosphere furnace again, and under the nitrogen protective atmosphere, the temperature of the atmosphere furnace was raised to 600°C; then 35L of acetylene gas was evenly introduced into the atmosphere furnace within 1 hour while the introduction of nitrogen gas was stopped to obtain SiOx @C-G Composite negative electrode mater...

Embodiment 2

[0089] Pulverize the SiO coarse particles in the pulverizer, the speed of the pulverizer is 1600 rpm, pulverize the pulverized material in the jet pulverizer for 0.5h, and then pulverize the pulverized material in the jet pulverizer, the jet pulverizer classifier is 1800 revolutions / min; the gas flow pressure is preferably 0.8 MPa, and the SiO precursor with a particle size of 1 μm-7 μm will be obtained.

[0090] Mix 2kg of SiO precursor, 100g of dispersant, and 10kg of graphene slurry evenly, then spray dry and granulate. The temperature of the drying air inlet is 220°C, and the temperature of the air outlet is 90°C. The obtained SiO-G precursor was then placed in an atmosphere furnace, and under a nitrogen protective atmosphere, the temperature of the atmosphere furnace was raised to 600°C; then 35L of acetylene gas was evenly introduced into the atmosphere furnace within 1 hour while the introduction of nitrogen was stopped; The temperature of the atmosphere furnace was rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com