Same-frequency confocal LED lighting source structure for detecting three-dimensional defects on surface of product

A technology of LED lighting and the same frequency, applied in the direction of using optical devices, measuring devices, optical testing flaws/defects, etc., can solve the problems of poor heat dissipation, insufficient lighting light source, etc., to achieve high overall stability, good lighting effect, Low calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

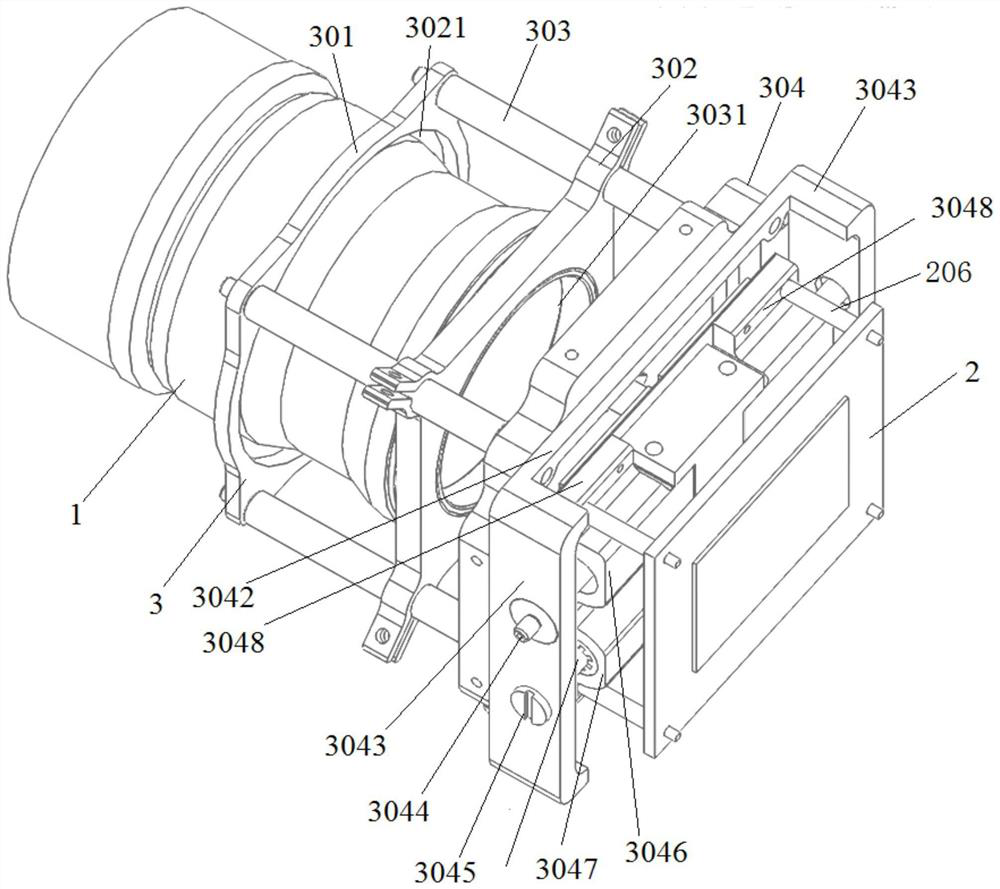

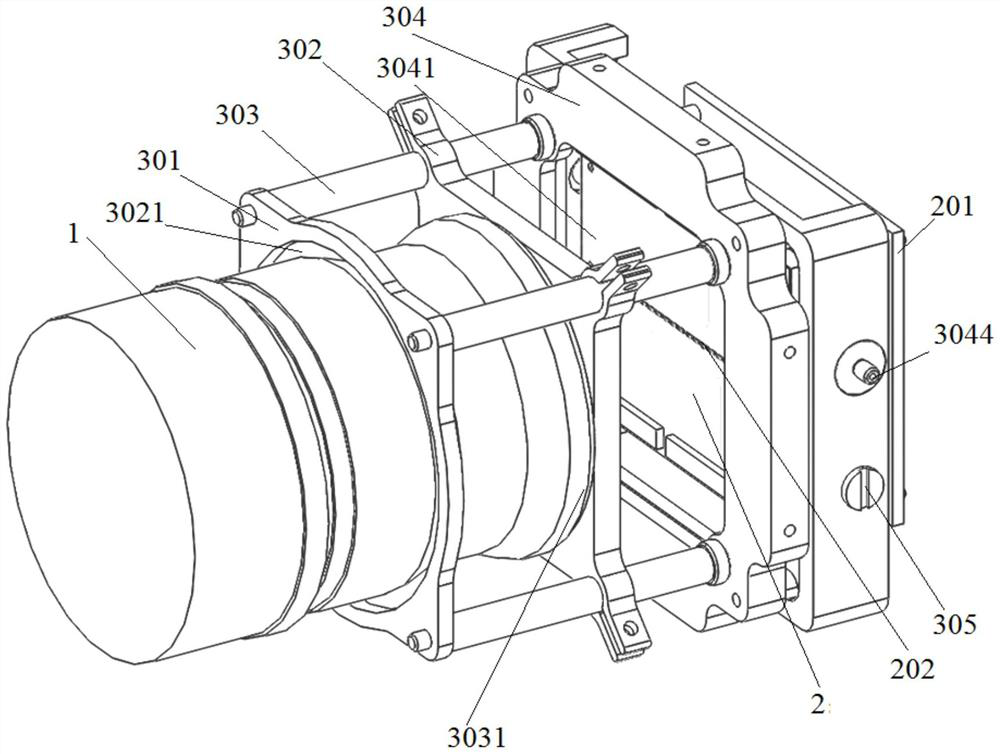

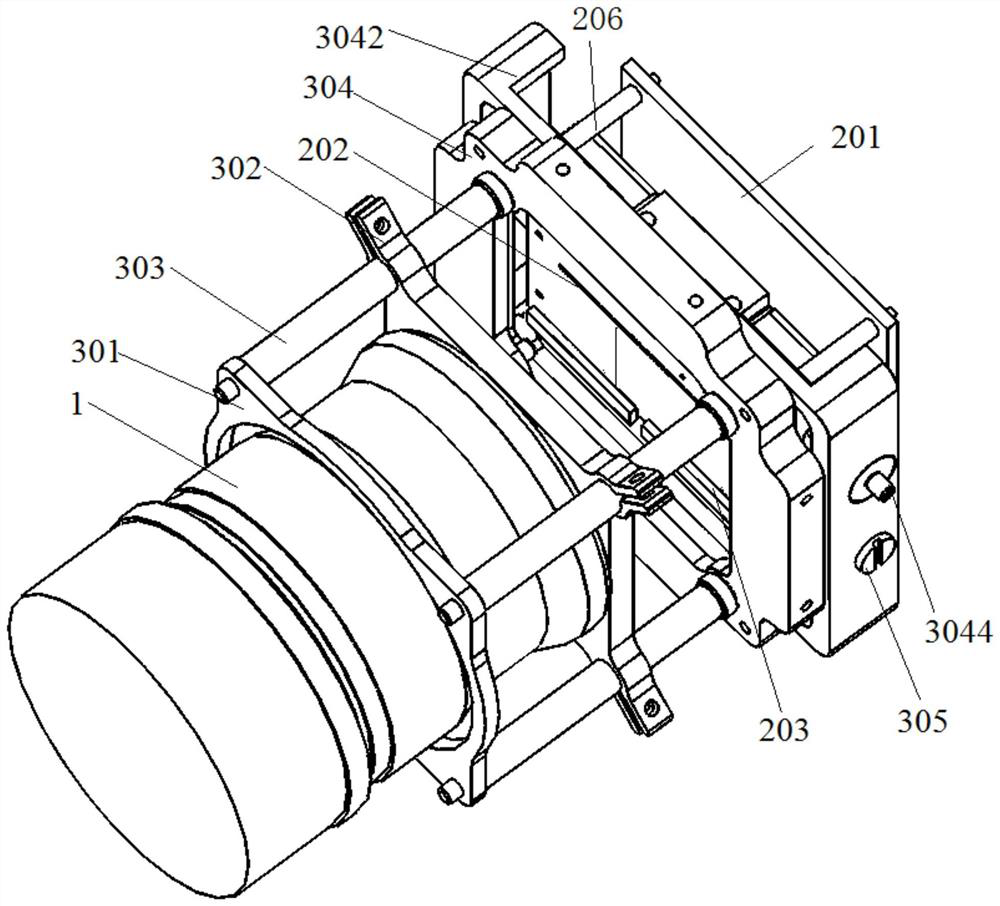

[0034] Such as Figure 1-Figure 5 As shown, the same-frequency confocal LED lighting source structure for product surface three-dimensional defect detection of the present invention includes a sampling lens assembly 1, an LED lighting source assembly 2 and an adjustable lighting position bracket 3,

[0035] The LED lighting source assembly 2 is installed on the rear end of the sampling lens assembly 1 through an adjustable lighting position bracket 3,

[0036] The LED lighting source assembly 2 is a confocal LED lighting source with the same frequency, and the LED lighting beads inside can be turned on or off under single-point control. The unit lights up or goes out sequentially according to the clock frequency of the linear array CCD sensor pixel points sequentially exposed along the working direction, so that the LED lighting source assembly 2 and the linear array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com