Replacement lining plate assembly of manganese steel lining plate supporting draw shaft damaged lining plate and installation method thereof

A liner and component technology, applied in the installation of bolts, shaft equipment, wellbore lining, etc., can solve the problems that the liner cannot be suspended for a long time, the speed of repairing damage is fast, and the maintenance frequency is increased. High strength and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

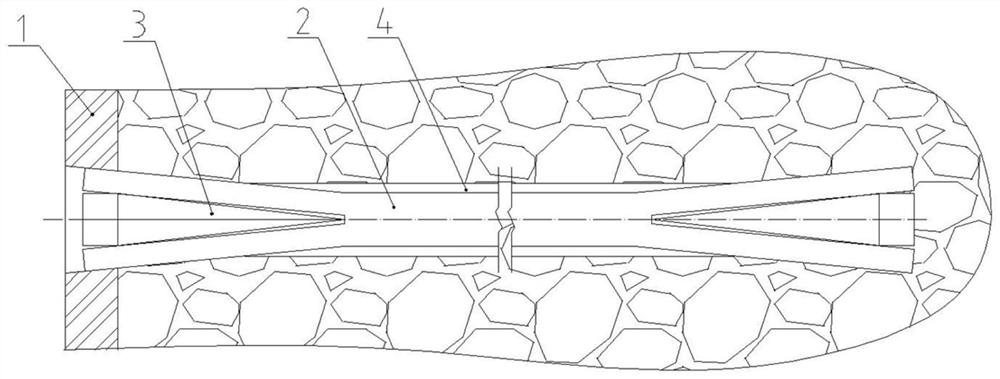

[0025] combine Figure 1 to Figure 5 It can be seen that the replacement liner assembly for the manganese steel liner supporting the damaged liner of the chute disclosed in this embodiment includes a replacement liner 1 , an anchor rod 2 and a steel wedge 3 .

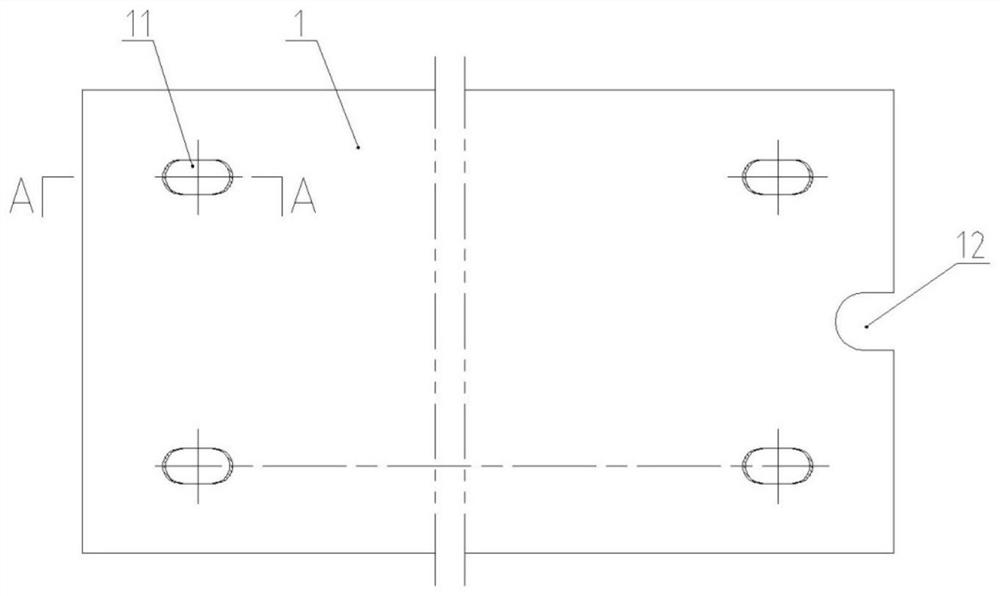

[0026] The replacement liner 1 is a rectangular thick plate, and its four corners are symmetrically provided with anchor holes 11. The anchor holes are oblong holes, and along the thickness direction of the replacement liner, they are tapered with a large outside and a small inside.

[0027] A grouting hole 12 is also provided on the replacement liner.

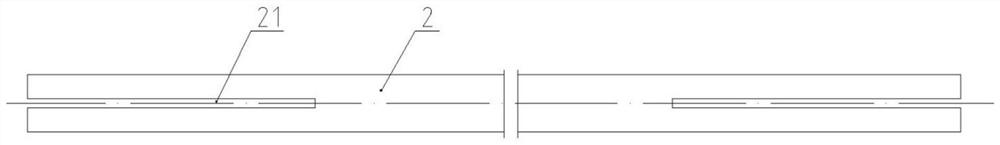

[0028] The anchor rod 2 is round steel, and its two ends are symmetrically provided with rectangular grooves 21 along the axial center plane.

[0029] The steel wedge 3 includes a pointed wedge and a cylindrical wedge on its outside. The total length of the steel wedge is the same as the length of the rectangular groove, and the width is not greater than the outer diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com