Negative buoyancy immersed tube and prefabricating method thereof

A technology of negative buoyancy and immersed tubes, which is applied in water conservancy projects, artificial islands, underwater structures, etc., and can solve the problems of increasing the amount of backfilling of the main structure and foundation trench, increasing the cost of prefabrication and construction, and the high section height of pipe joints. and other issues, to achieve the effect of saving prefabrication cost and construction cost, reducing the difficulty of design and prefabrication, and reducing the height of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

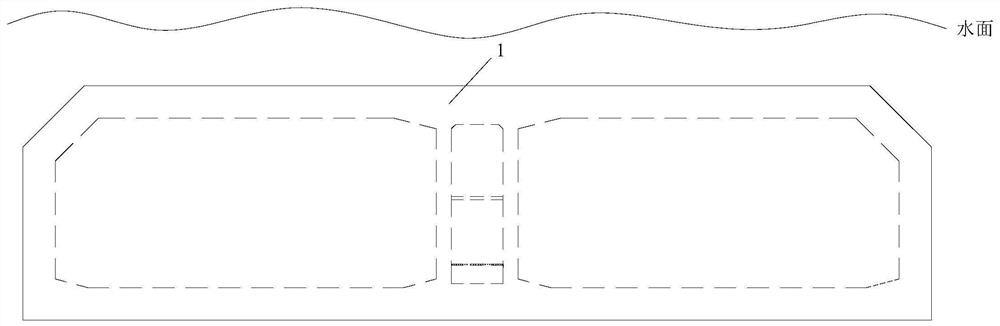

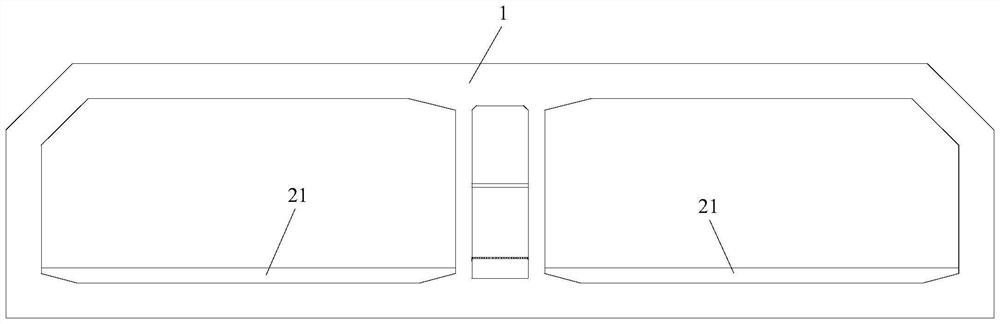

[0044] like figure 1As shown, a negative buoyancy immersed tube according to the present invention includes a body 1, and the design freeboard value of the body 1 is less than 0. That is, a negative freeboard pipe joint, that is, the design of the positive freeboard is not considered. It is not necessary to design the pipe joint to be self-floating in the corresponding water area, but to form the negative buoyancy state of the existing immersed tube in the sinking and docking links. It breaks the design concept that self-floating and sinking tubes must be used in the prior art, and can minimize the structural height, save the main structure, backfilling of foundation grooves and other engineering quantities, and do not need to set freeboard adjustment layers.

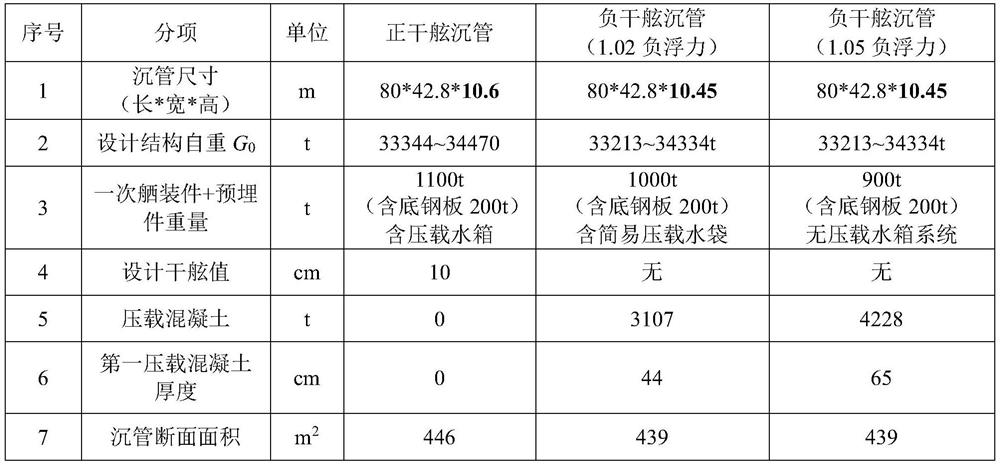

[0045] Specifically, the self-weight of the body 1 includes the self-weight G of the design structure of the body 1 0 And the design self-weight of the ballast concrete inside the body 1, wherein the design structure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com