Method for preparing water-permeable brick from construction waste

A technology of construction waste and permeable bricks, applied in ceramic products, applications, household appliances, etc., can solve the problem that construction waste cannot make good use of permeable bricks, achieve good antifouling function, improve crushing efficiency, and ensure the effect of water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

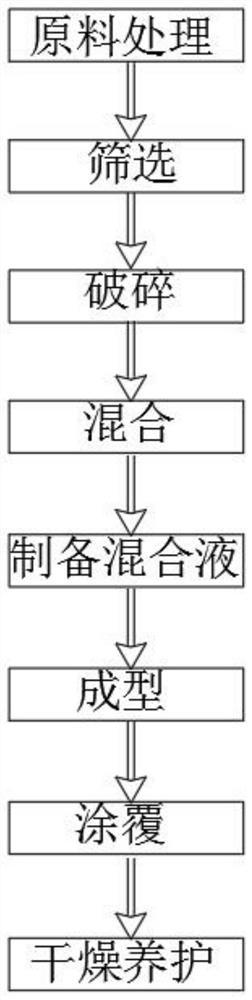

[0033] refer to figure 1 , a kind of construction waste material prepares the method for permeable brick, comprises the following steps:

[0034] S1: Raw material treatment, take 200-300 parts of discarded construction waste and crush it with a pressure testing machine or hammer it;

[0035] S2: screening: screening with 200-300 mesh sieves;

[0036] S3: crushing, put 20-50% of the raw materials obtained in S2 into the crusher for continuous crushing;

[0037] S4: Mixing, put the raw materials obtained in S2 and S3 into a mixer for mixing, add auxiliary materials during mixing, and prepare a slurry;

[0038] S5: Prepare a mixed solution, prepare 20-40 parts of reinforcing fiber, 10-30 parts of glass fiber and 10-35 parts of asphalt to mix with each other, and obtain the mixed solution of the surface layer of the permeable brick after the mixing is completed;

[0039] S6: Forming, adding the slurry into the forming machine, vibrating and pressurizing, and making preliminary ...

Embodiment 2

[0045] refer to figure 1 , a kind of construction waste material prepares the method for permeable brick, comprises the following steps:

[0046] S1: Raw material treatment, take 250-300 parts of discarded construction waste and crush it with a pressure testing machine or hammer it;

[0047] S2: screening: screening with a 200-mesh sieve;

[0048] S3: crushing, put 25-50% of the raw materials obtained in S2 into the crusher for continuous crushing;

[0049] S4: Mixing, put the raw materials obtained in S2 and S3 into a mixer for mixing, add auxiliary materials during mixing, and prepare a slurry;

[0050] S5: Prepare a mixed solution, prepare 25-40 parts of reinforcing fiber, 10-30 parts of glass fiber and 10-35 parts of asphalt and mix with each other. After the mixing is completed, the mixed solution for the surface layer of the permeable brick can be obtained;

[0051] S6: Forming, adding the slurry into the forming machine, vibrating and pressurizing, and making prelimi...

Embodiment 3

[0057] refer to figure 1 , a kind of construction waste material prepares the method for permeable brick, comprises the following steps:

[0058] S1: Raw material treatment, take 260-300 parts of discarded construction waste and crush it with a pressure testing machine or hammer it;

[0059] S2: screening: screening with a 300-mesh sieve;

[0060] S3: crushing, put 20-50% of the raw materials obtained in S2 into the crusher for continuous crushing;

[0061] S4: Mixing, put the raw materials obtained in S2 and S3 into a mixer for mixing, add auxiliary materials during mixing, and prepare a slurry;

[0062] S5: Prepare a mixed solution, prepare 20-35 parts of reinforcing fiber, 10-30 parts of glass fiber and 10-35 parts of asphalt to mix with each other, and obtain the mixed solution of the surface layer of the permeable brick after the mixing is completed;

[0063] S6: Forming, adding the slurry into the forming machine, vibrating and pressurizing, and making preliminary per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com