Preparation method of autoclaved lightweight high-strength high-fly-ash-content ceramsite

A fly ash, lightweight technology, applied in the field of ceramsite preparation, can solve the problems of difficult control of raw materials, complicated process of fly ash ceramsite, etc., and achieve the effects of expanding utilization channels, improving comprehensive utilization rate, and preventing cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

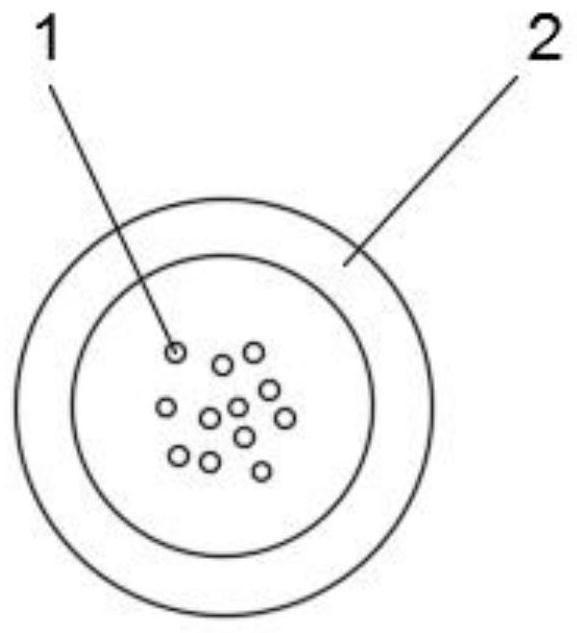

Image

Examples

Embodiment 1

[0036] A method for preparing autoclaved light-weight, high-strength, high-fly ash-incorporated ceramsite, comprising the following steps:

[0037] Step S1, raw material preparation: drying the desulfurized gypsum at 50°C to constant weight, weighing fly ash, cement, quicklime, water glass, desulfurized gypsum and aluminum powder;

[0038] Step S2, raw material mixing: put 70% fly ash, cement, quicklime, water glass, desulfurized gypsum and aluminum powder into a V-shaped mixing mixer to make a mixture;

[0039] Step S3, preparation of wet material: weigh a certain amount of water, add it into a V-shaped mixing mixer, and prepare a wet material with a certain humidity;

[0040] Step S4: Pour the wet material prepared in step S3 into the ball plate at one time, turn on the ball plate, rotate at a low speed of 280r / min for 2min, then rotate at a medium speed of 560r / min for 2min, and then turn it at a high speed 700r / min, rotate for 2min, the spheres are sticking to each other,...

Embodiment 2

[0048] A method for preparing autoclaved light-weight, high-strength, high-fly ash-incorporated ceramsite, comprising the following steps:

[0049] Step S1, raw material preparation: drying the desulfurized gypsum at 50°C to constant weight, weighing fly ash, cement, quicklime, water glass, desulfurized gypsum and aluminum powder;

[0050] Step S2, raw material mixing: put 70% fly ash, cement, quicklime, water glass, desulfurized gypsum and aluminum powder into a V-shaped mixing mixer to make a mixture;

[0051] Step S3, preparation of wet material: weigh a certain amount of water, add it into a V-shaped mixing mixer, and prepare a wet material with a certain humidity;

[0052] Step S4: Pour the wet material prepared in step S3 into the ball plate at one time, turn on the ball plate, rotate at a low speed of 290r / min for 3min, then rotate at a medium speed of 580r / min for 3min, and then turn it at a high speed 750r / min, rotate for 3min, the spheres are sticking to each other,...

Embodiment 3

[0060] A method for preparing autoclaved light-weight, high-strength, high-fly ash-incorporated ceramsite, comprising the following steps:

[0061] Step S1, raw material preparation: drying the desulfurized gypsum at 50°C to constant weight, weighing fly ash, cement, quicklime, water glass, desulfurized gypsum and aluminum powder;

[0062] Step S2, raw material mixing: put 70% fly ash, cement, quicklime, water glass, desulfurized gypsum and aluminum powder into a V-shaped mixing mixer to make a mixture;

[0063] Step S3, preparation of wet material: weigh a certain amount of water, add it into a V-shaped mixing mixer, and prepare a wet material with a certain humidity;

[0064] Step S4: Pour the wet material prepared in step S3 into the pelletizing tray at one time, turn on the pelletizing tray, rotate at a low speed of 300r / min for 4min, then rotate at a medium speed of 600r / min for 4min, and then turn it at a high speed 800r / min, rotate for 4 minutes, the spheres are sticki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com