Special construction process for mounting stacker-reclaimer gantry

A construction technology and reclaimer technology, applied in the directions of safety devices, loading/unloading, transportation and packaging, etc., can solve problems such as large span of hoisting gantry, heavy hoisting weight, and inapplicability of scheme 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

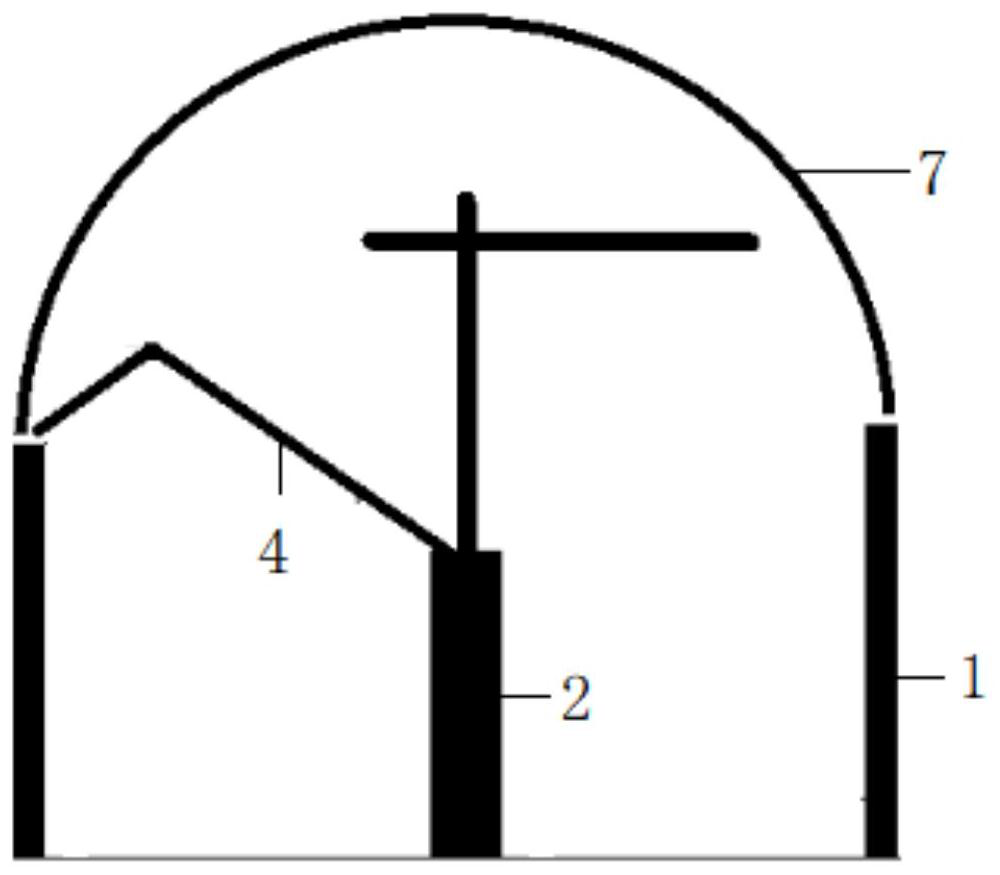

[0052] A special construction process for installing a stacker-reclaimer door frame, comprising the following steps:

[0053] Step 1. Crane station setting

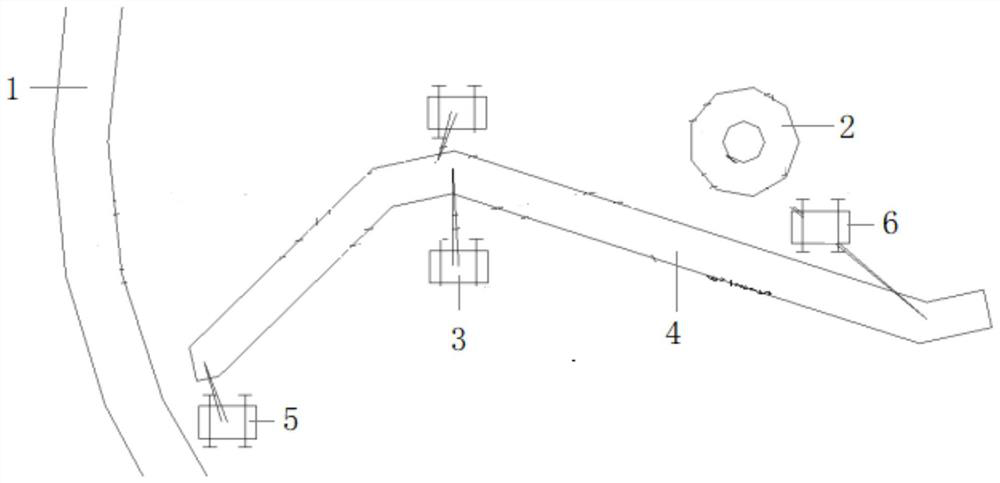

[0054] Four truck cranes are used for hoisting, among which two 350t truck cranes are the main cranes. Bind it firmly with steel wire ropes. The lifting point of a 130t truck crane is set near the central column of the mast (point B, the center of the support of section A), and the lifting point of the other 80t truck crane is set on the side of the mast traveling mechanism ( Point C, which is the center of the support of section E of the gantry), each lifting point is fixed with a steel wire rope, and the A, B and C lifting points of the gantry are all made of 6*37+1-φ64mm steel wire ropes, and the A lifting point of the gantry Use two 6*37+1-φ64mm steel wire ropes to go around the single arm of the mast twice, and choose the appropriate wire rope to reduce the possibility of breakage during hoisting;

[0055] Step 2. ...

Embodiment 2

[0110] Embodiment 2 application example

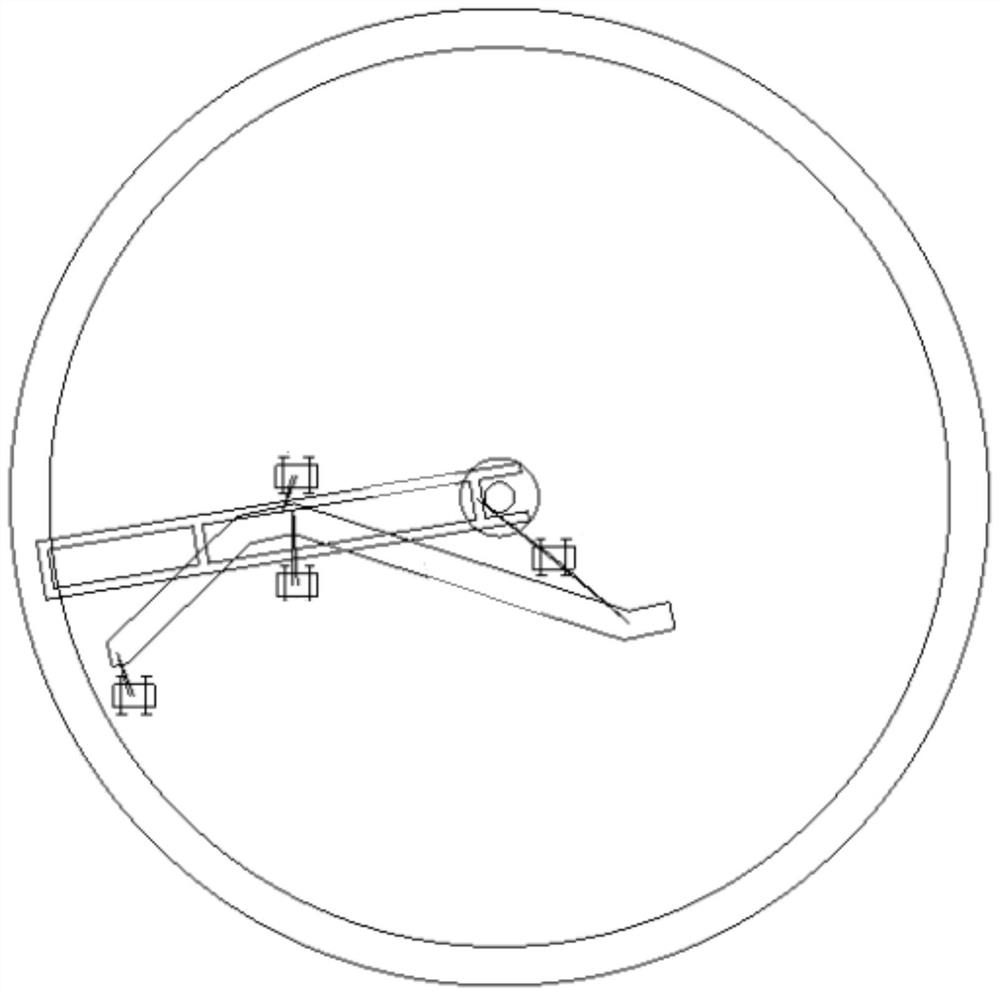

[0111] Inner Mongolia Jiutai New Material Co., Ltd. Coal Transportation Island Project with an annual output of 1 million tons of ethylene glycol

[0112] Project overview: Inner Mongolia Jiutai New Material Co., Ltd. has an annual output of 1 million tons of ethylene glycol project. The round coal yard of the coal handling island adopts the round stockyard stacker and reclaimer produced by Huadian Heavy Industry Co., Ltd., and its portal frame installation applies this construction craft. In this project, three circular coal yards with a diameter of Φ100m will be built, and the height of the coal retaining wall will be 16.5m. The coal storage capacity of a single circular coal yard is about 10×104t, and the total coal storage capacity of the three circular coal yards is about 30×104t, which can be used for about 20 days by the boiler and gasifier of this phase of the project. According to the requirements of the owner, incoming coal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com