Selective wave soldering method and system for PCB repair

A PCB board and selective technology, applied in the field of selective wave soldering methods and systems for PCB board repair, can solve the problems of time-consuming, laborious, misjudgment and missed judgment, so as to improve the product qualification rate and avoid misjudgment and leakage. The effect of judgment and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

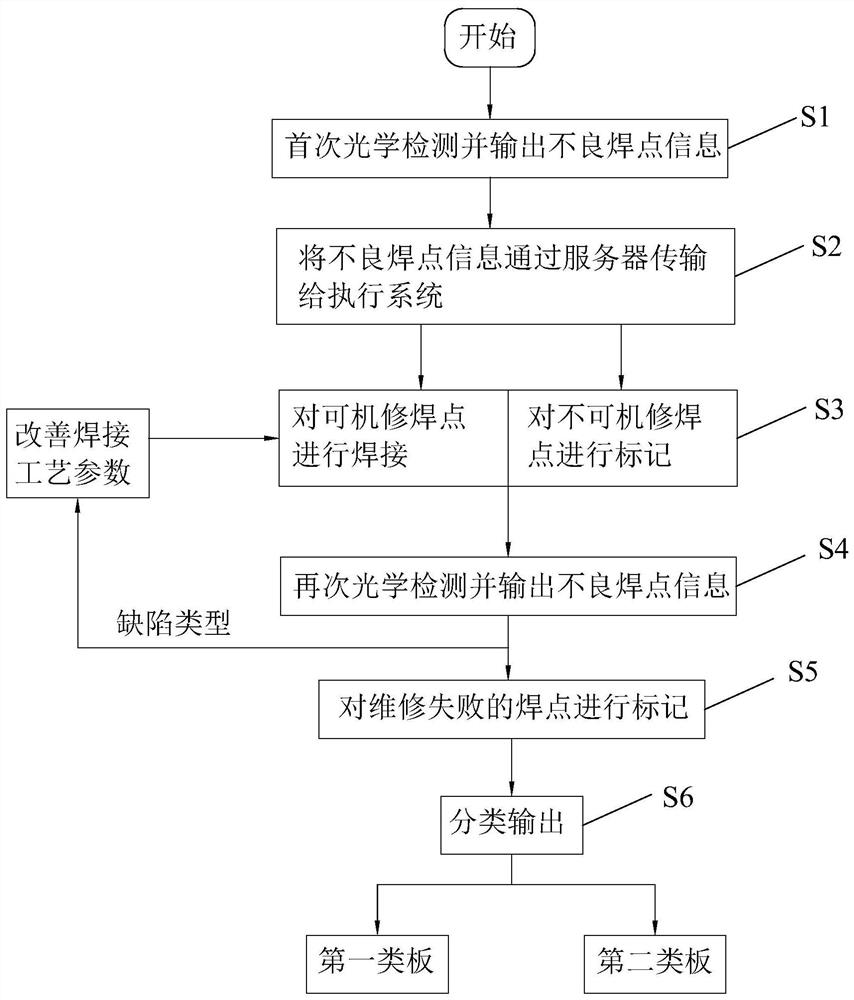

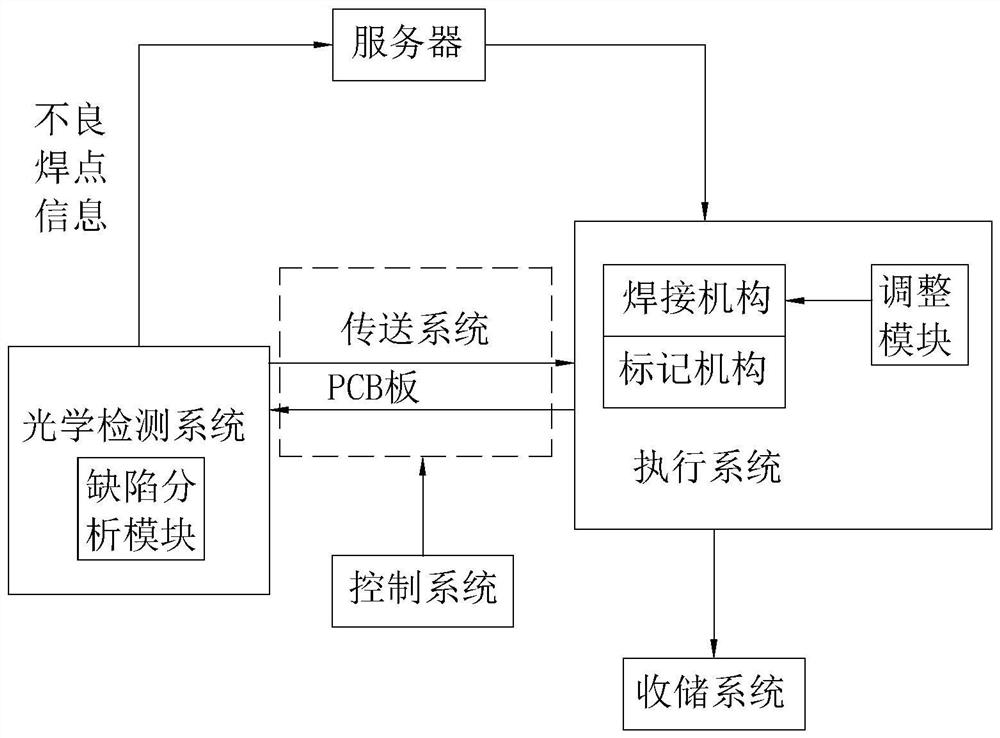

[0043] like figure 1 As shown, this embodiment discloses a selective wave soldering method for repairing a PCB, that is, the defective solder joints on the PCB are repaired through a selective wave soldering process. Specifically, the selective wave soldering method includes the following steps:

[0044]S1: Use the optical inspection system to inspect the solder joints on the PCB board to be processed to obtain information on bad solder joints on the PCB. The bad solder joint information includes the bad type of bad solder joints and the coordinates of the solder joints. The bad types include machine repairable (defective) Relatively light, it can be automatically repaired by machine welding) and not machine repairable (the defect is rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com