High-temperature-resistant foam pouring cup and processing technology thereof

A pouring cup, high temperature resistance technology, applied in metal processing equipment, manufacturing tools, coatings, etc., can solve the problems of reducing production costs, sputtering, easy cracking of molten iron, etc. The effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

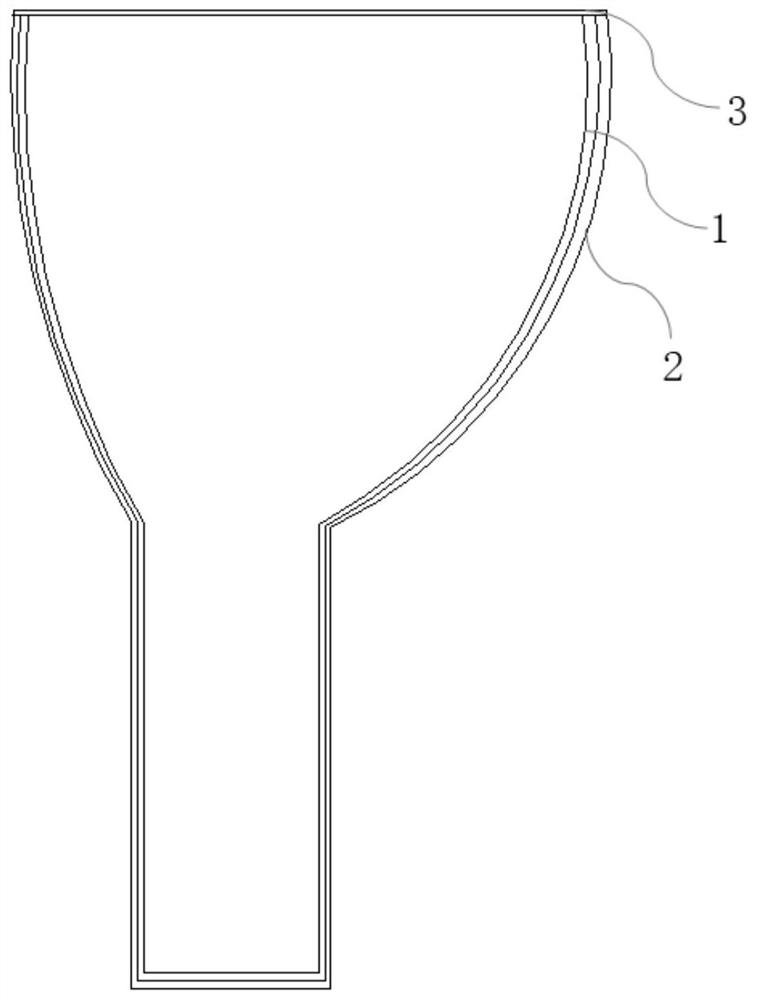

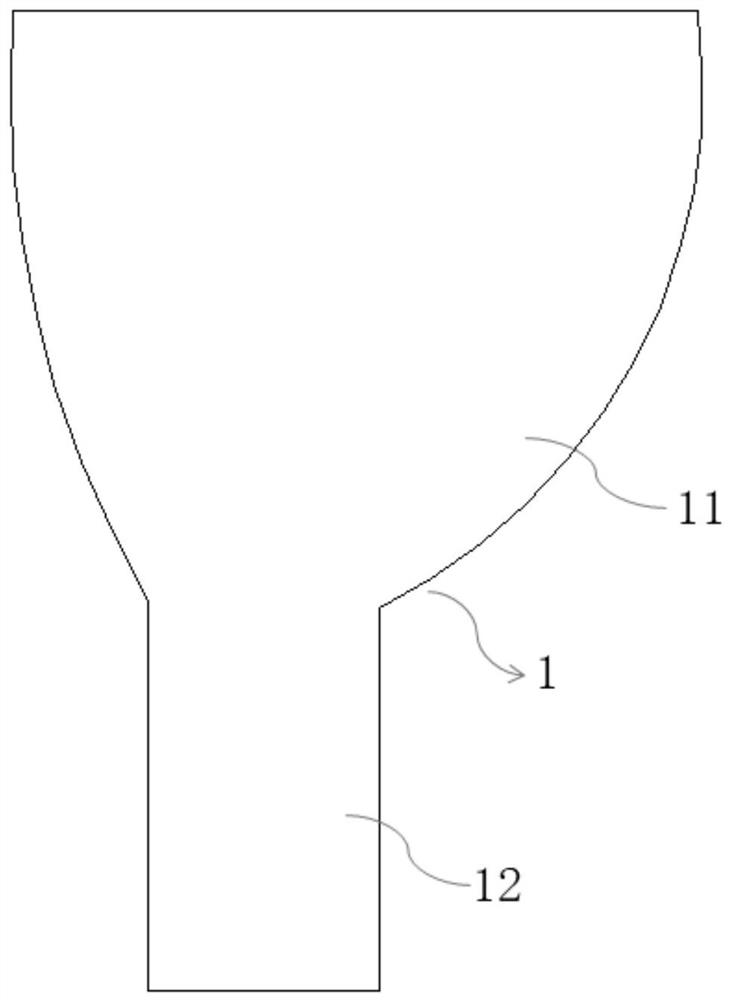

[0033] A kind of high temperature resistant foam sprue cup and its processing technology of the present embodiment, such as Figure 1 to Figure 3 As shown, the sprue cup 1 is made of foam and includes a sprue cup body 11 and a sprue channel 12 connected thereunder. The diameter of the sprue cup 1 gradually decreases from top to bottom. The sprue cup body 11 The cross-section of the sprue cup body 11 is asymmetrically elliptical, and the cross-sectional area of the sprue cup body 11 is larger than that of the gate channel 12, and the gate channel 12 is circular or square; The entrance of the cup 1 is pasted with a cloth film seal 3, and the outer wall of the sprue cup 1 is coated with a high temperature resistant layer 2.

[0034] The shape design of the main body 11 of the sprue cup is compared with the sprue cup 1 of the positive taper. When the molten iron is poured, it can prevent the molten iron from spinning and splashing out in the sprue cup 1, causing harm to the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com