M iron lug plate forming device

A forming device and iron lug technology, which is applied in the field of electric poles, can solve the problems of restricting mass production of products, low processing precision, and high scrap rate, and achieve the effects of low scrap rate, high processing accuracy, and high bending tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

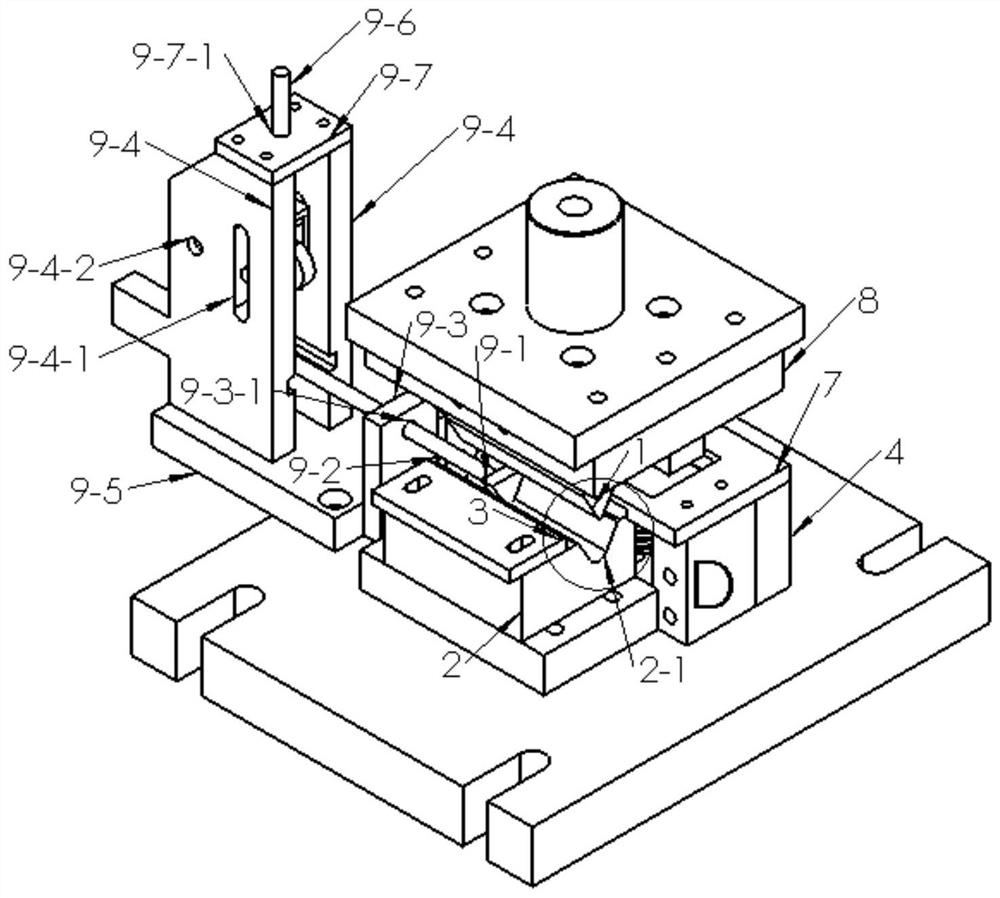

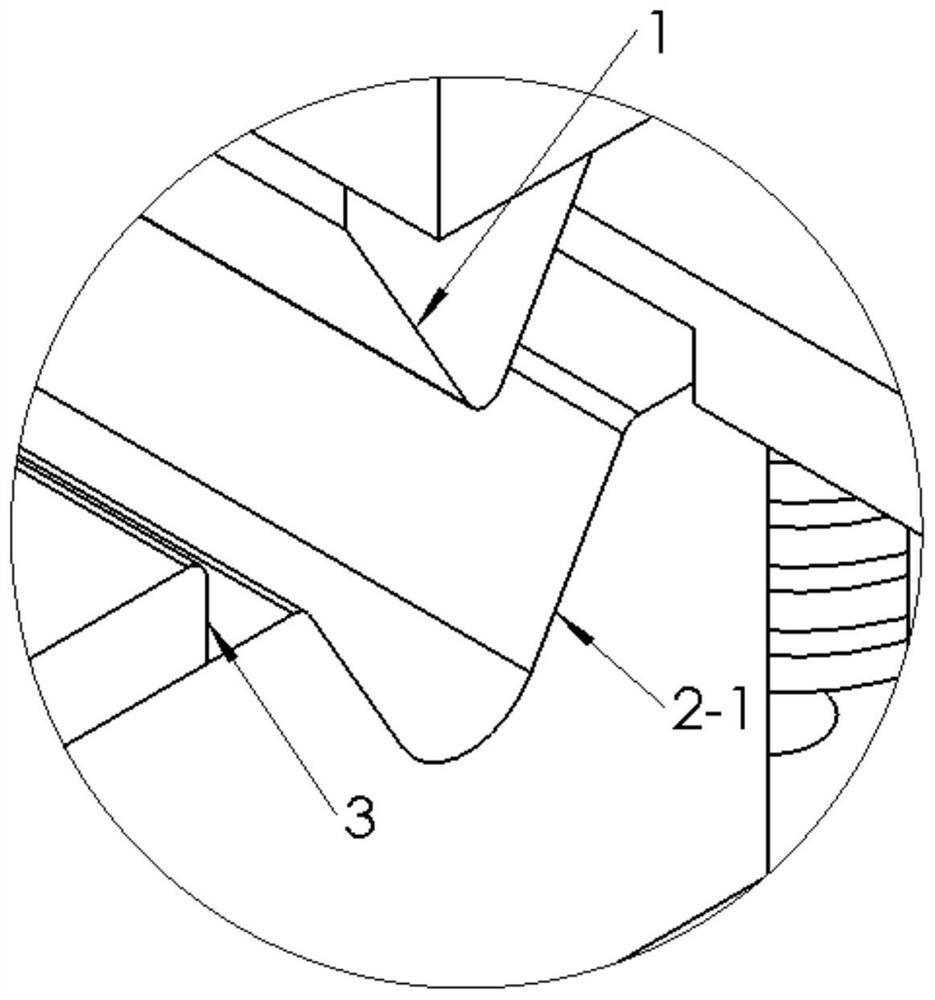

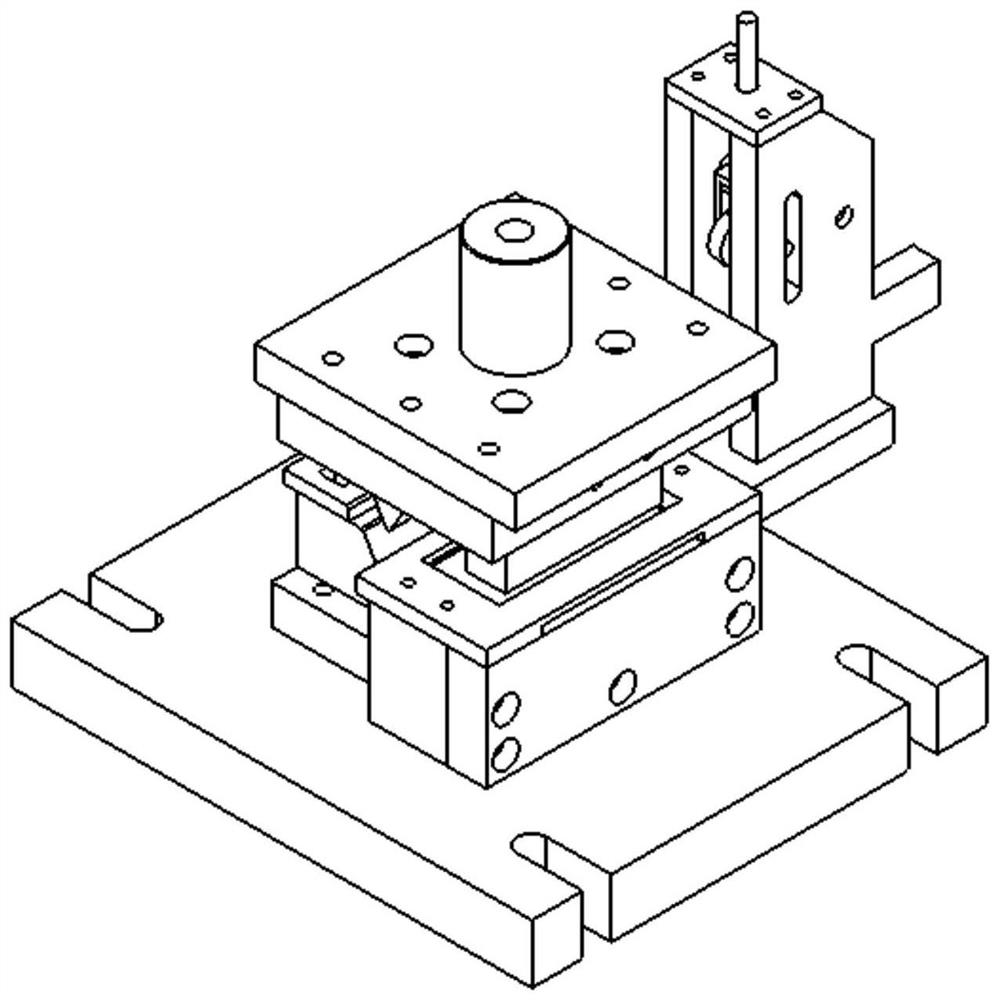

[0053] Example 1: Reference Figure 1 to Figure 8 , a M iron ear plate forming device, comprising: a bending upper die 1, the bending upper die 1 is a regular triangular prism cylinder, one side of the bending upper die 1 is perpendicular to the direction of movement of the bending upper die 1 , the length of the bottom side of the bending upper die 1 is 30mm, the side edge of the lower part of the bending upper die 1 is arc chamfering, and the radius of the arc chamfering is 2mm; the bending lower die 2 is set on the bending lower die 2 There is a groove 2-1, the groove 2-1 is a regular triangular prism, the groove 2-1 is located directly below the bending upper die 1, and one of the sides of the groove 2-1 is perpendicular to the movement direction of the bending upper die 1, The length of the bottom surface of the groove 2-1 is 35mm, the side edge of the lower part of the groove 2-1 is arc chamfered, the radius of the arc chamfer is 8mm, the intersection line between the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com