Bending machine with combined clamping mechanism

A technology of clamping mechanism and bending machine, which is applied in the field of bending machine, can solve the problems of complex operation and unsuitability for small workshops, and achieve the effects of low cost, concise bending action and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the direction in the figure, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

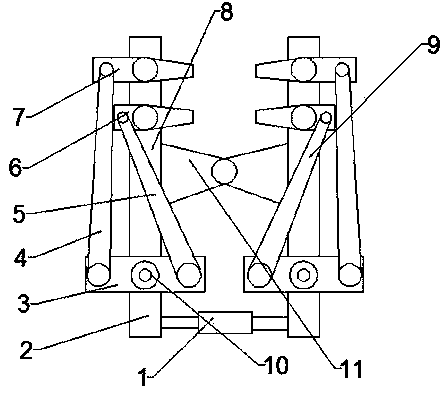

[0011] Such as figure 1 The shown bending machine with a combined clamping mechanism includes a left clamping mechanism 8, the left clamping mechanism 8 includes a support plate 2, the lower end of the support plate 2 is connected with a rotating plate 3, and the The middle part of the rotating plate 3 is connected with the steering gear 10 , the right end of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com