Roller for part cleaning in thermal treatment process for continuous type mesh belt furnace and cleaning machine

A mesh belt furnace and drum technology, applied in the field of cleaning machines, can solve problems such as parts sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

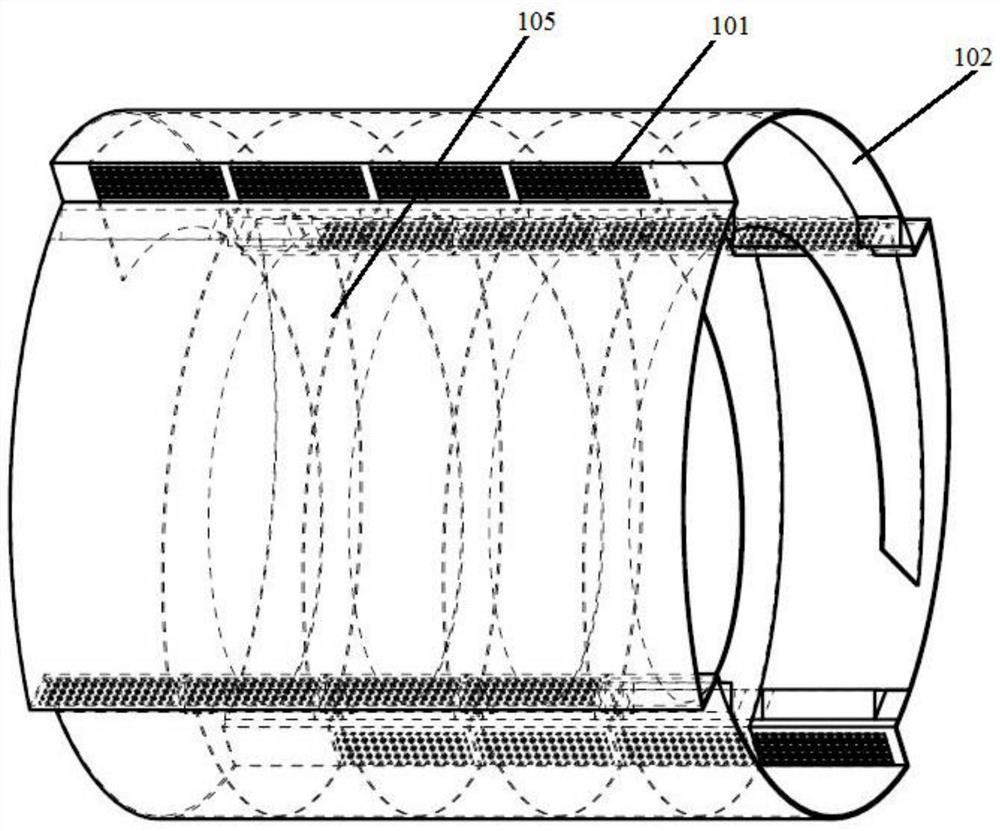

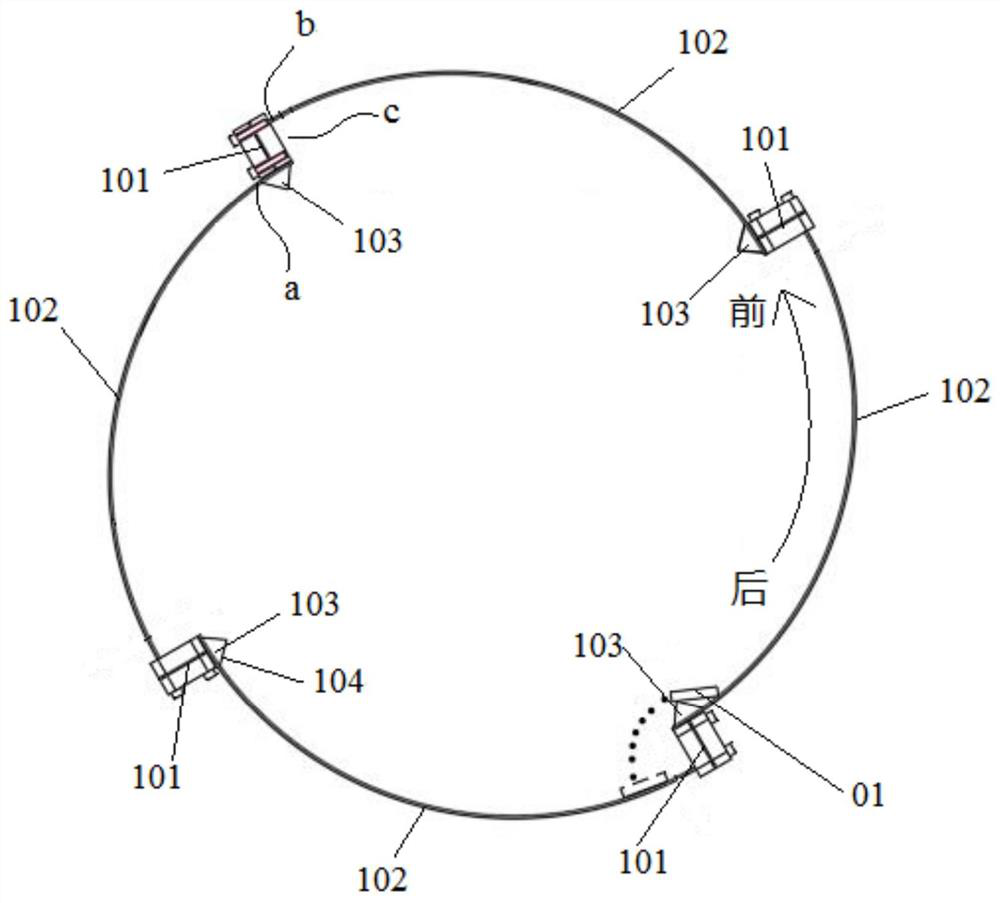

[0025] In the heat treatment process of the continuous mesh belt furnace, before the parts are tempered, the quenching oil on the surface of the parts will be cleaned by a drum cleaning machine. The washing machine specifically includes a drum, a driving part and a transmission part that drive the drum to rotate.

[0026] The driving part can specifically adopt a motor, and the transmission part can specifically adopt a chain assembly. The driving sprocket of the chain assembly is connected with the output shaft of the motor, the driven sprocket is arranged on the outer periphery of the drum, and the chain is tensioned between the driving sprocket and the driven sprocket. between. This drive transmission mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com