A hydraulic valve reversing buffer device

A buffer device and hydraulic valve technology, applied in the field of hydraulic valves, can solve problems such as uncoordinated actions of actuators, ignoring the control requirements of spool flow accuracy, unfavorable fine operation of construction machinery, etc., so as to improve safety and improve operation Improvement of comfort and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

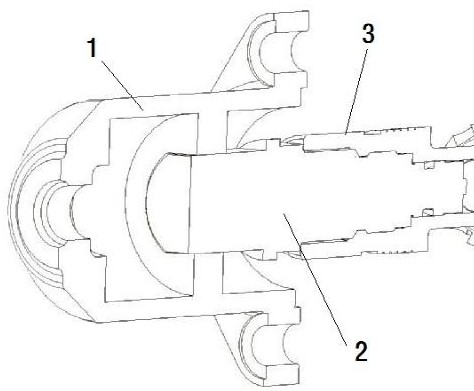

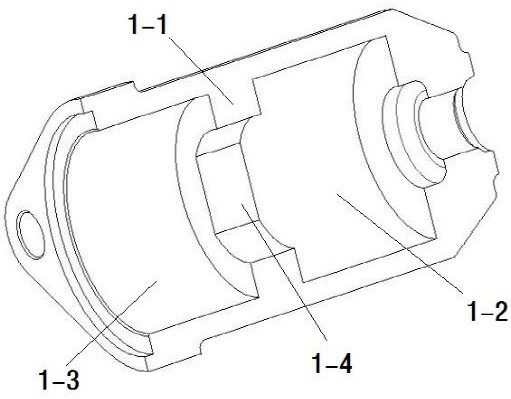

[0023] combine Figure 1 to Figure 3 As shown, a hydraulic valve reversing buffer device includes an end cover 1 , an anti-rotation screw plug 2 and a valve stem 3 , and the anti-rotation screw plug 2 is located between the end cover 1 and the valve stem 3 . The end connected to the valve stem 3 on the anti-rotation screw plug 2 has an external thread, and the end of the valve stem 3 has a threaded blind hole.

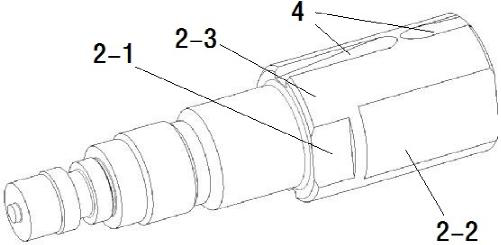

[0024] combine figure 2 As shown, the inner end of the anti-rotation screw plug 2 is a guide section 2-1. A guide surface 2-2, a mounting plane 2-3 and a throttling groove 4 are provided on the circumferential surface of the guide section 2-1. The guide section 2-1 is cylindrical, and two symmetrically arranged guide surfaces 2-2 are milled on the guide section 2-1, and the section at the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com