Construction method of individualized 3D printing acetabular wall defect repairing and reconstructing system

A 3D printing and construction method technology, applied in 3D printing, acetabular recess, prosthesis, etc., can solve the problem of lack of individual 3D printing acetabular wall defect repair and reconstruction system construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

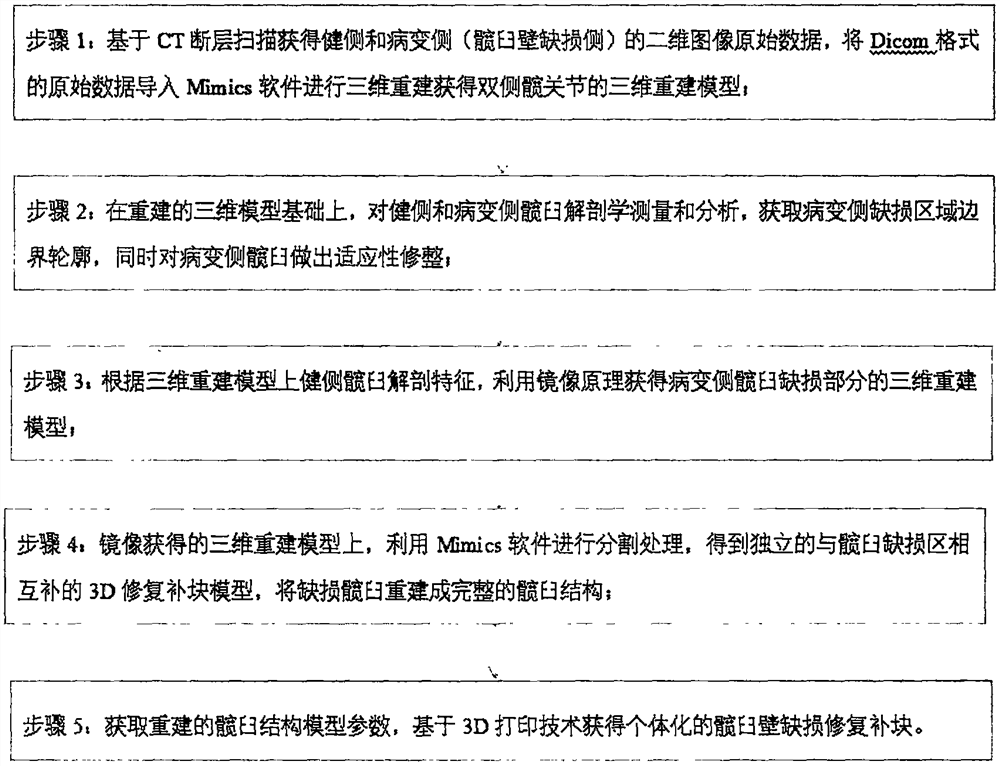

[0043] Such as figure 1 shown

[0044] A method for constructing an individualized 3D printed acetabular wall defect repair and reconstruction system, comprising the following steps:

[0045] Step 1: Acquisition and processing of image data of acetabular wall defect

[0046] Based on CT tomography, the raw data of two-dimensional images of the healthy side and the lesion side (the acetabular wall defect side) were obtained, and the original data in Dicom format were imported into Mimics software for three-dimensional reconstruction to obtain a three-dimensional reconstruction model;

[0047] The three-dimensional model reconstruction is based on imaging software, and the three-dimensional model of the acetabulum is reconstructed by using functions of threshold segmentation (Thresholding) and region growing (Region growing).

[0048] Step 2: Anatomical analysis of the 3D reconstruction model and adaptive trimming of the lesion side

[0049] On the basis of the reconstructed ...

Embodiment 2

[0065] Application of a construction method of individualized 3D printing acetabular wall defect repair and reconstruction system in the preoperative planning of hip replacement for acetabular wall defect reconstruction;

[0066] A 64-slice spiral CT (GE Company, USA) was used for thin-slice scanning of bilateral hip joints of patients with acetabular wall defects, and the original CT image data was imported into Mimics 20.0 software (Materialise Company, Belgium) in Dicom format. The functions of segmentation (Thresholding) and region growing (Region growing) respectively reconstruct the 3D model of the bilateral hip joints, and based on the mirror function (Mirror) the mirror operation is performed on the healthy hip joints with the mid-sagittal position as a reference, and the hip joints on the affected side are identified. The position, shape and geometric size of the acetabular defect, through the measurement and analysis of the geometric size and topographic map of the de...

Embodiment 3

[0072] Clinical application of a construction method of individualized 3D printing acetabular wall defect repair and reconstruction system in hip dysplasia and total hip replacement.

[0073] Based on 3D printing technology, the size and shape of the acetabular defect was produced, combined with traditional THA operations, the repair and reconstruction system was implanted in the defect area, and mechanically fixed to repair the acetabular defect and correct the shape of the affected acetabulum, making the diseased acetabulum Restoring the complete geometric structure, and then implanting the acetabular cup prosthesis in a unified operation method according to the traditional method, the complicated operation is simplified, and the follow-up operation of THA is completed.

[0074] The size, shape and contour curve of the manufactured acetabular defect repair and reconstruction system conform to the size of the patient's 3D printed acetabular defect bone block, and the curvature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com