Inductor

A technology of inductors and external electrodes, applied in the field of inductors, can solve the problems of reduced insulation and inability to obtain sufficient withstand voltage performance, and achieve sufficient withstand voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

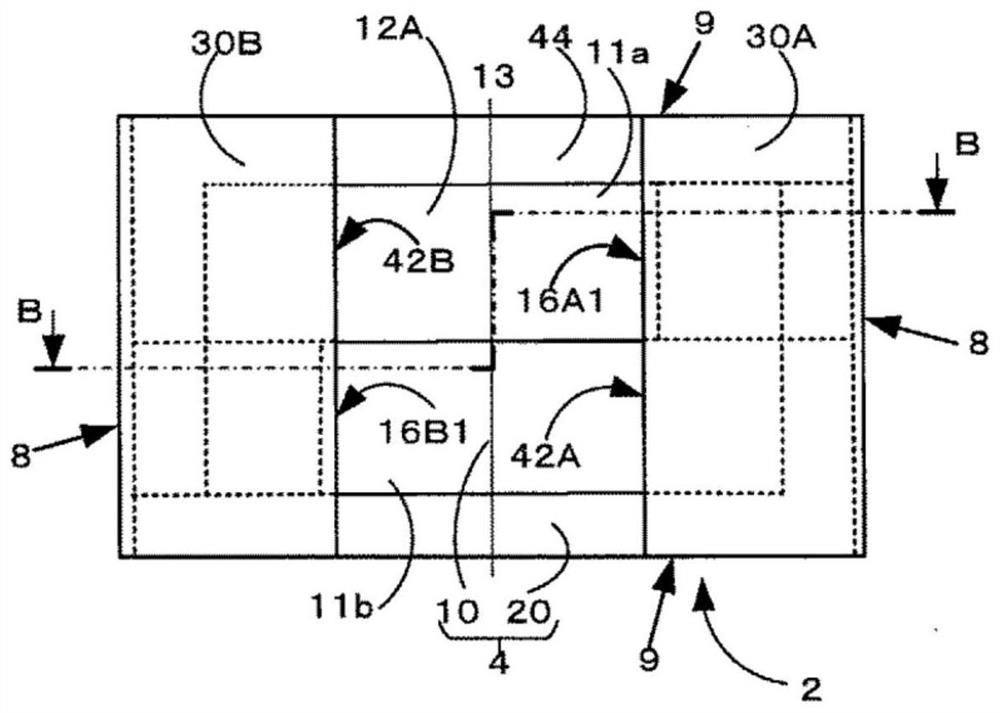

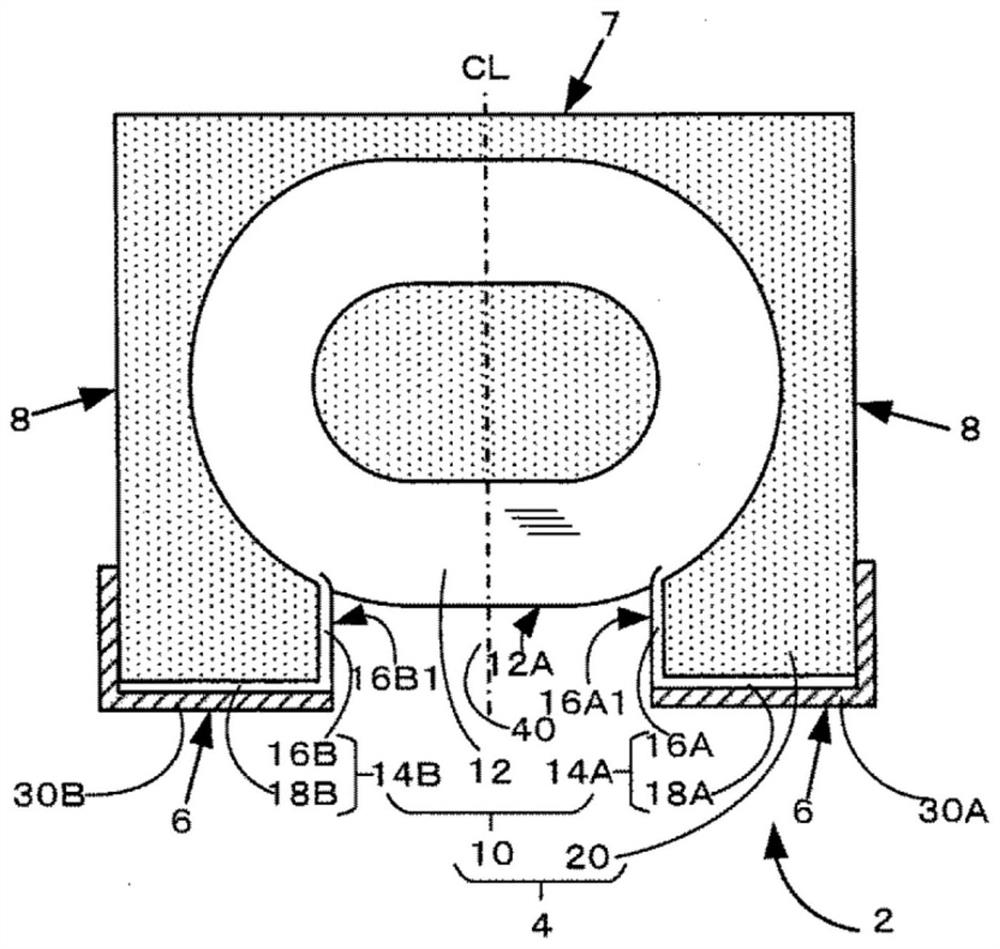

[0037] First, refer to Figure 1A , Figure 1B as well as Figure 1C The inductor according to the first embodiment of the present invention will be described. Figure 1A It is a side view schematically showing the outer shape of the inductor according to the first embodiment of the present invention. Figure 1B is a schematic representation of the mounting surface side of the inductor Figure 1A Bottom view of arrow A-A. Figure 1C is a schematic representation Figure 1B Side sectional view of section B-B. In addition, in Figure 1C , shows cross sections at different height positions on the left and right of the central line CL.

[0038] The inductor 2 according to the present embodiment includes a base body 4 having a substantially rectangular parallelepiped shape, and the base body 4 has a coil 10 and a magnetic body 20 that seals the coil 10 . The magnetic body 20 is made of magnetic powder and resin. The inductor 2 is a surface-mounted device having a mounting sur...

no. 2 approach

[0085] Next, refer to Figure 3A , Figure 3B as well as Figure 3C An inductor according to a second embodiment of the present invention will be described. Figure 3A It is a side view schematically showing the outer shape of the inductor according to the second embodiment of the present invention. Figure 3B is a schematic representation of the mounting surface side of the inductor Figure 3A Bottom view of the arrow E-E, Figure 3C is a schematic representation Figure 3B A side sectional view of section F-F. Figure 3C also with Figure 1C Similarly, the area on the right represents the winding portion 12 from which one lead-out portion 14A is drawn out. Figure 3B The cross-section of the segment 11a on the middle and upper side, the area on the left represents the winding portion 12 from which the other lead-out portion 14B is drawn out. Figure 3B The cross-section of the section 11b on the middle and lower side.

[0086] The second embodiment is different from...

no. 3 approach

[0090] Next, refer to Figure 4A , Figure 4B as well as Figure 4C An inductor according to a third embodiment of the present invention will be described. Figure 4A It is a side view schematically showing the outline of the inductor according to the second embodiment of the present invention, Figure 4B is a schematic representation of the mounting surface side of the inductor Figure 4A The bottom view of the arrow C-C, Figure 4C is a schematic representation Figure 4B Side cutaway view of section D-D. Figure 4C also with Figure 1C Similarly, the area on the right represents the winding portion 12 from which one lead-out portion 14A is drawn out. Figure 4B The cross-section of the segment 11a on the middle and upper side, the area on the left represents the winding portion 12 from which the other lead-out portion 14B is drawn out. Figure 4B The cross-section of the section 11b on the middle and lower side.

[0091] In the third embodiment, the difference from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com