Selective-permeability membrane and method for manufacturing same

A manufacturing method and permeable membrane technology, applied in semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of easy peeling and damage, high fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

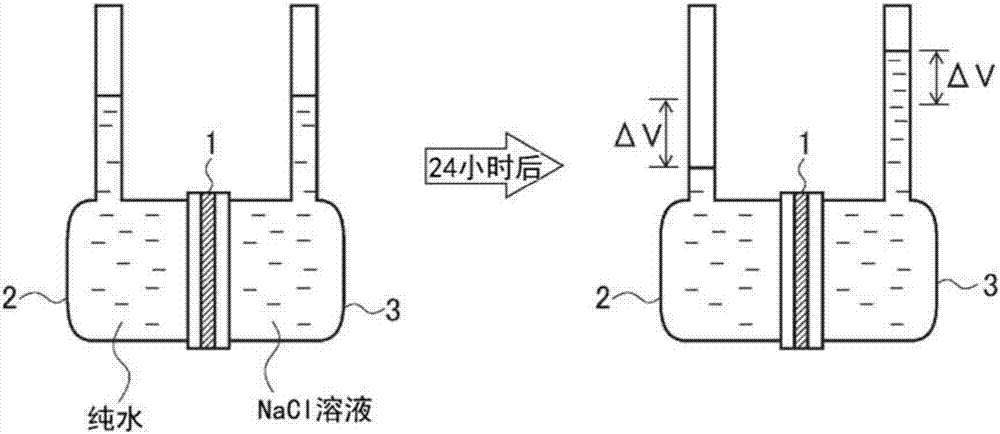

Problems solved by technology

Method used

Image

Examples

Embodiment

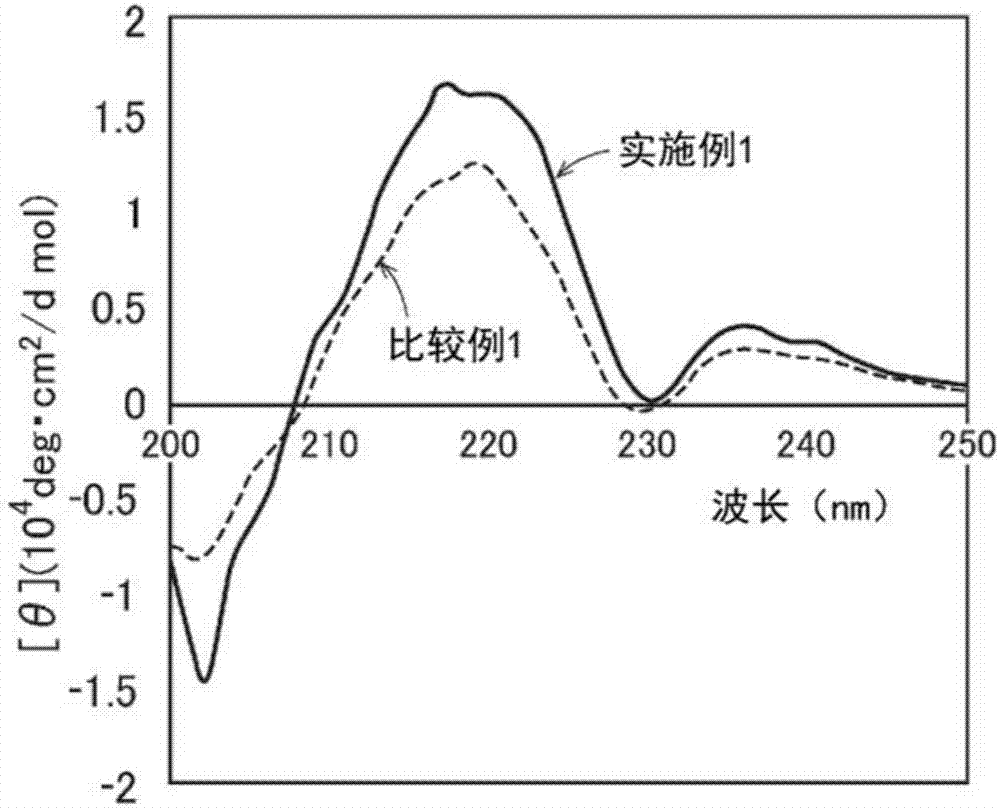

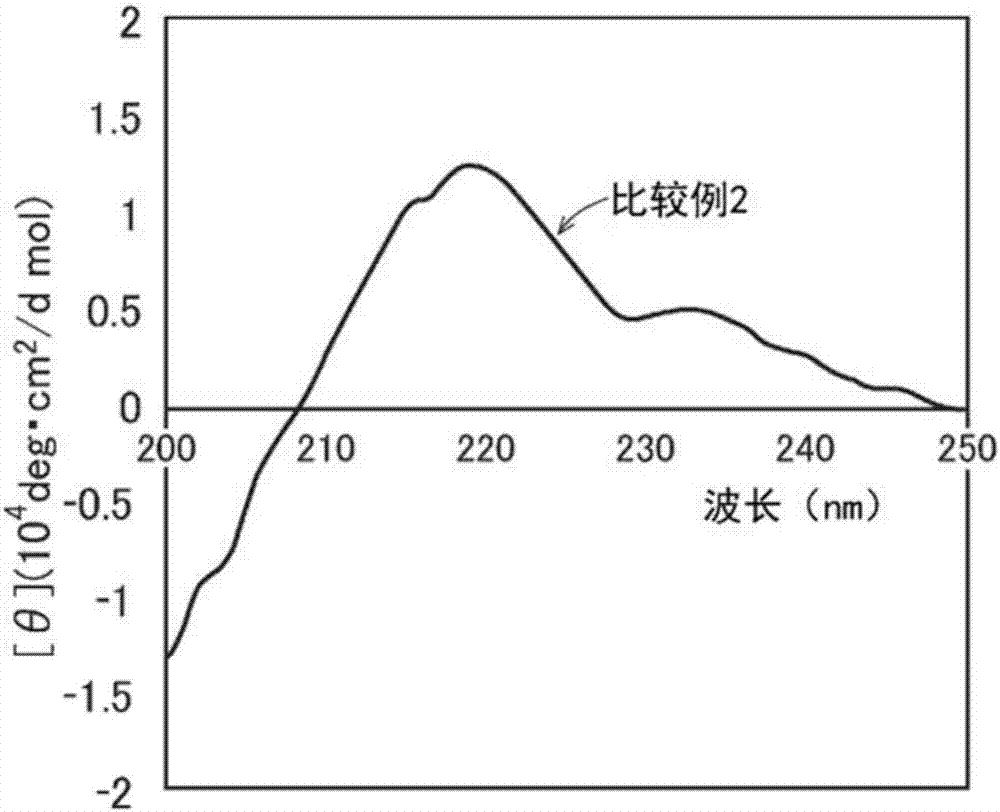

[0054] Hereinafter, examples and comparative examples will be described. Materials used, evaluation methods, etc. will be described.

[0055] [film body]

[0056] In the following examples and comparative examples, a film such as anodized aluminum oxide (Anodisc manufactured by Whatman Co., Ltd., diameter 25 mm, pore diameter 20 nm) was used as the main body of the film.

[0057] [phospholipids]

[0058] 1-palmitoyl-2-oleoyl-sn-glyceroyl-3-phosphatidylcholine (POPC, phase transition temperature -2°C, manufactured by NOF Corporation) was used as the first phospholipid containing unsaturated fatty acid in the acyl group .

[0059] 1,2-dipalmitoyl-sn-glyceroyl-3-phosphatidylcholine (DPPC, phase transition temperature 41°C, manufactured by NOF Corporation) was used as the second phospholipid, and in the second phospholipid, the two acyl groups consisted of Saturated fatty acids with 16 carbon atoms.

[0060] [channel substance]

[0061] Gramicidin A (GA, manufactured by Sigm...

reference example 1

[0076] Phospholipids were dissolved in chloroform to prepare a POPC solution. The organic solvent was evaporated under reduced pressure, pure water was added to the dry lipid film remaining in the container, and the film was hydrated at 35°C to prepare a vesicle dispersion. The obtained vesicle dispersion was dipped alternately and repeatedly in liquid nitrogen and a water bath at 35° C. for 5 times by using the freeze-thaw method, so as to grow the particles. Using a polycarbonate track-etched membrane with a pore size of 0.1 μm, the vesicle dispersion was extruded, granulated, and diluted with pure water so that the lipid concentration was 0.4 mM.

[0077] The membrane body treated with the silane coupling agent was immersed in the vesicle dispersion for 2 hours to adsorb the phospholipid to the membrane body. Thereafter, ultrasonic cleaning was performed for 10 minutes to peel off excess phospholipids adsorbed on the main body of the film, thereby producing a POPC coating ...

reference example 2

[0079] Except having used DPPC instead of POPC as a phospholipid, it carried out similarly to Reference Example 1, the DPPC covering film was produced, and the salt leakage rate was measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com