Hydrogen filling hose

A hose and function technology, which is applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of hydrogen embrittlement of metal wires, and achieve the effect of suppressing hydrogen embrittlement and sufficient pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the hydrogen filling hose of the present invention will be described based on the embodiment shown in the drawings.

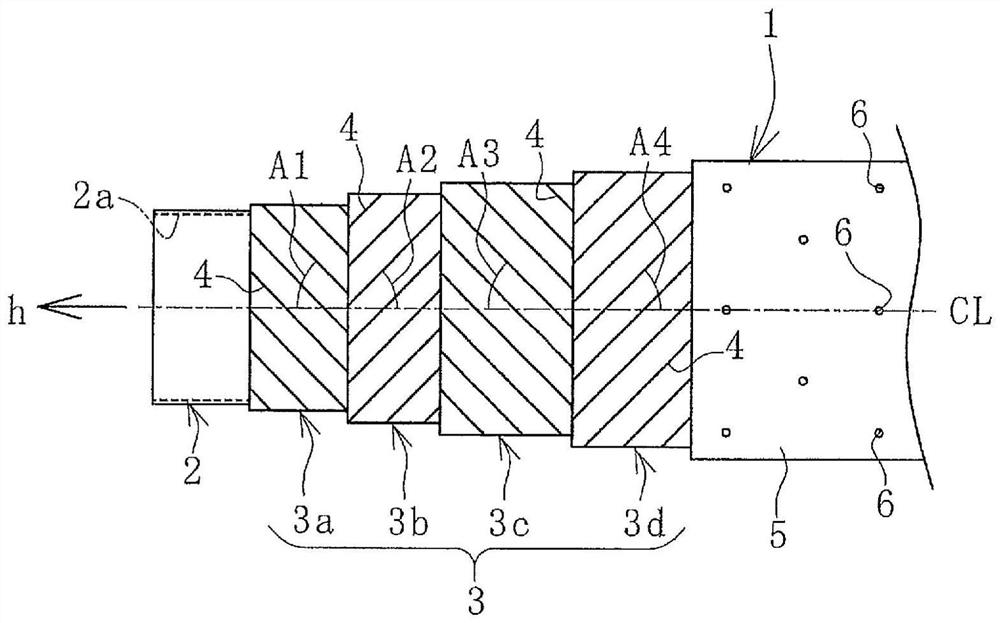

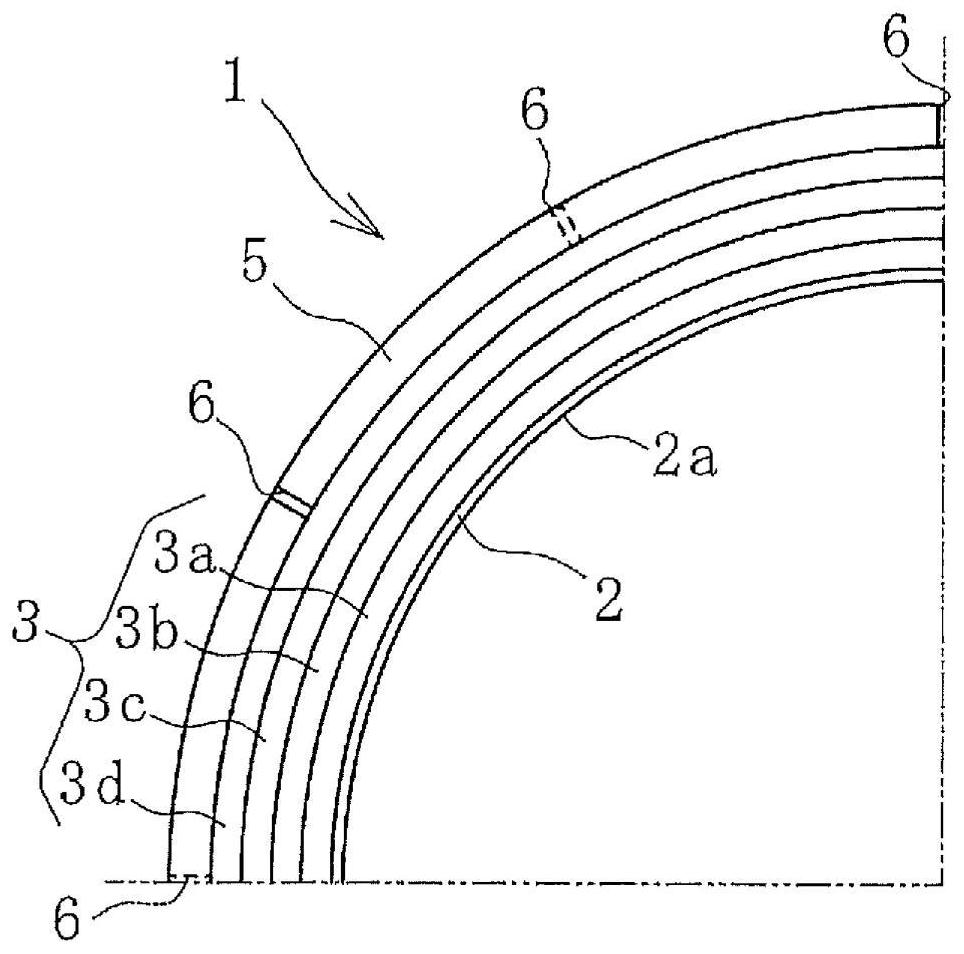

[0018] exist figure 1 , figure 2 In the embodiment of the hydrogen filling hose 1 (hereinafter referred to as hose 1) of the present invention illustrated in , the inner surface layer 2 and the reinforcing layer 3 (3a , 3b, 3c, 3d), the outer surface layer 5. The one-dot chain line CL in the drawing represents the axis of the hose.

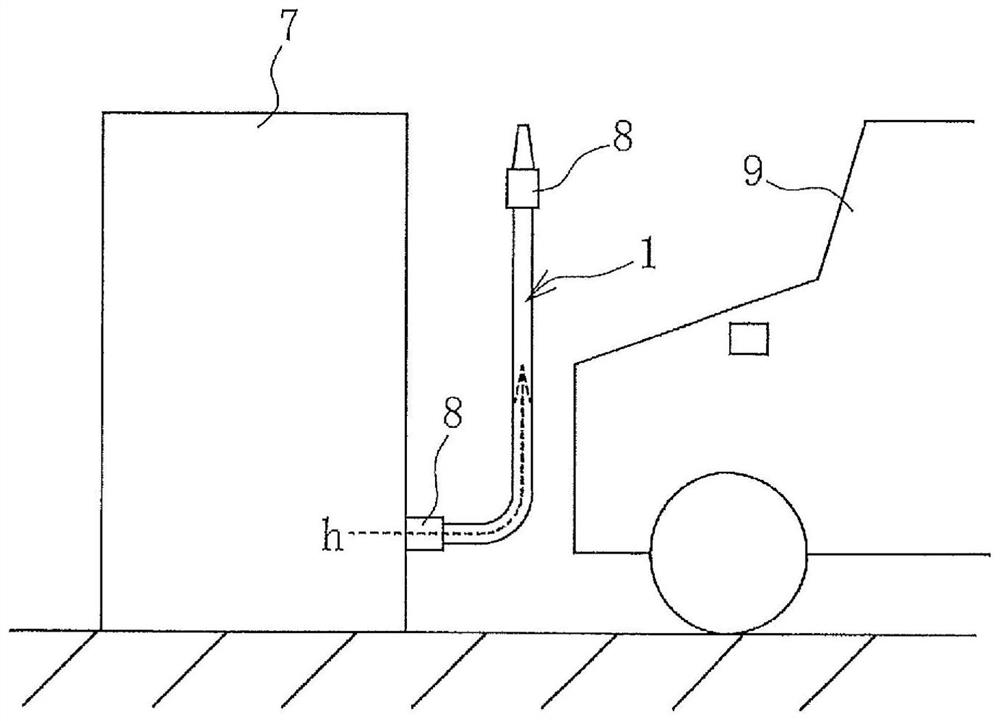

[0019] Such as image 3 As shown by way of example, when this hose 1 is equipped with a distributor 7 installed in a hydrogen refueling station, hose fittings 8 are riveted to both ends of the hose 1 . Low temperature (for example, minus 40° C. to minus 20° C.) and high pressure (for example, 70 MPa to 87.5 MPa) hydrogen gas is supplied and filled from the distributor 7 to the vehicle 9 , storage tank, etc. through the hose 1 . That is, the use internal pressure of the hose 1 is 70 MPa or more.

[0020] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com