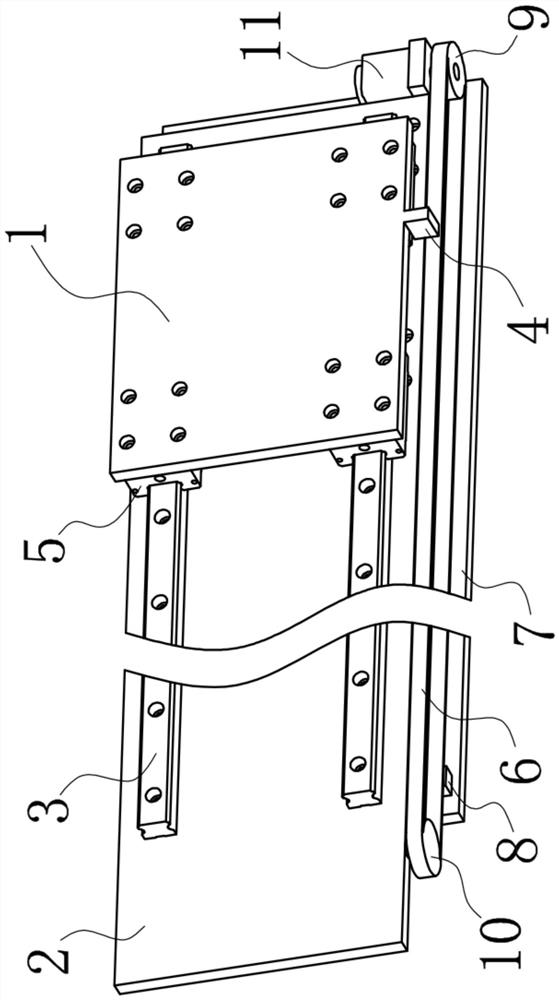

Folding linear module

A linear module and flat panel technology, applied in the direction of electric components, control mechanical energy, electrical components, etc., to achieve precise transmission, prevent movement, and precise movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

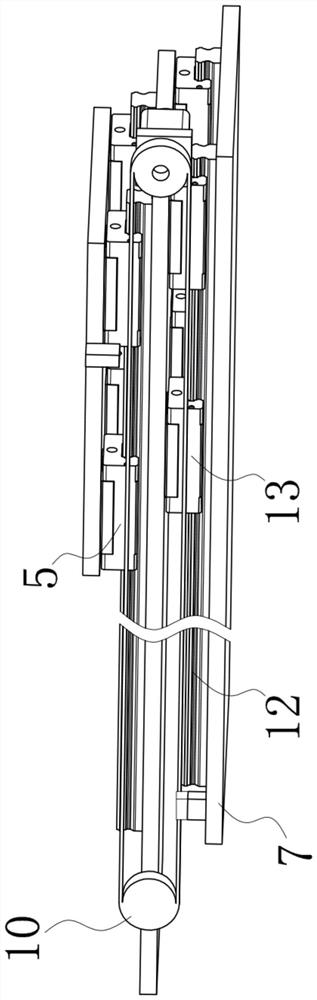

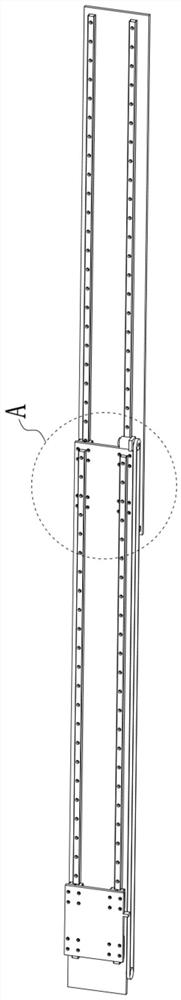

[0030] In order to achieve the purpose of the present invention, a folding linear module includes: a flat plate, including an upper flat plate 1, a middle flat plate 2, and a lower flat plate 7 arranged parallel to each other from top to bottom; The upper slide rail 3 between the flat plates 2 also includes a lower slide rail 12 arranged between the middle flat plate 2 and the lower flat plate 7; Driven wheel 10 is arranged, and one side of middle plate 2 is provided with the driving belt 6 that connects rotating power part, driven wheel 10, and driving belt 6 has upper running segment, lower running segment parallel to each other, and the length direction of upper running segment, lower running segment and The length direction of the slide rail is parallel, and the rotation plane of the rotating power part is parallel to the length direction of the slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com