Novel corrosion-resistant and wear-resistant metal ceramic slurry pump cylinder sleeve

A cermet, corrosion-resistant technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problem of poor corrosion resistance and wear resistance of metal cylinder liners, short service life of bimetallic cylinder liners, and easy Avoid problems such as shedding or crushing, achieve excellent wear resistance and corrosion resistance, ensure operating efficiency, and prevent mutual slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

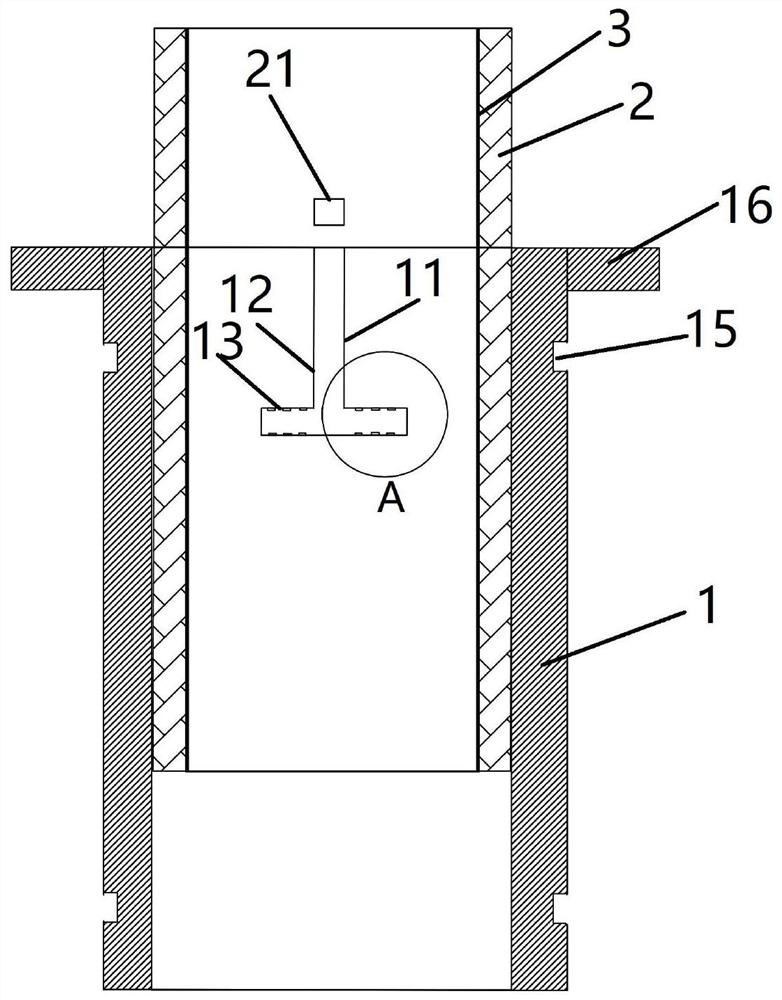

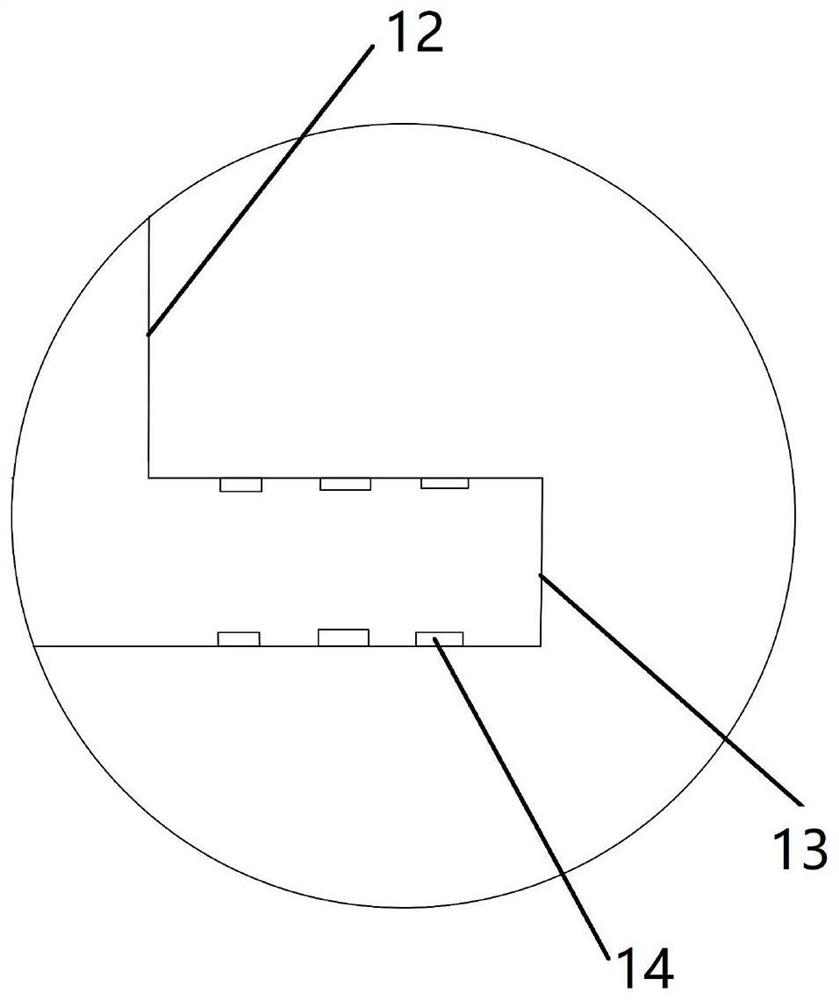

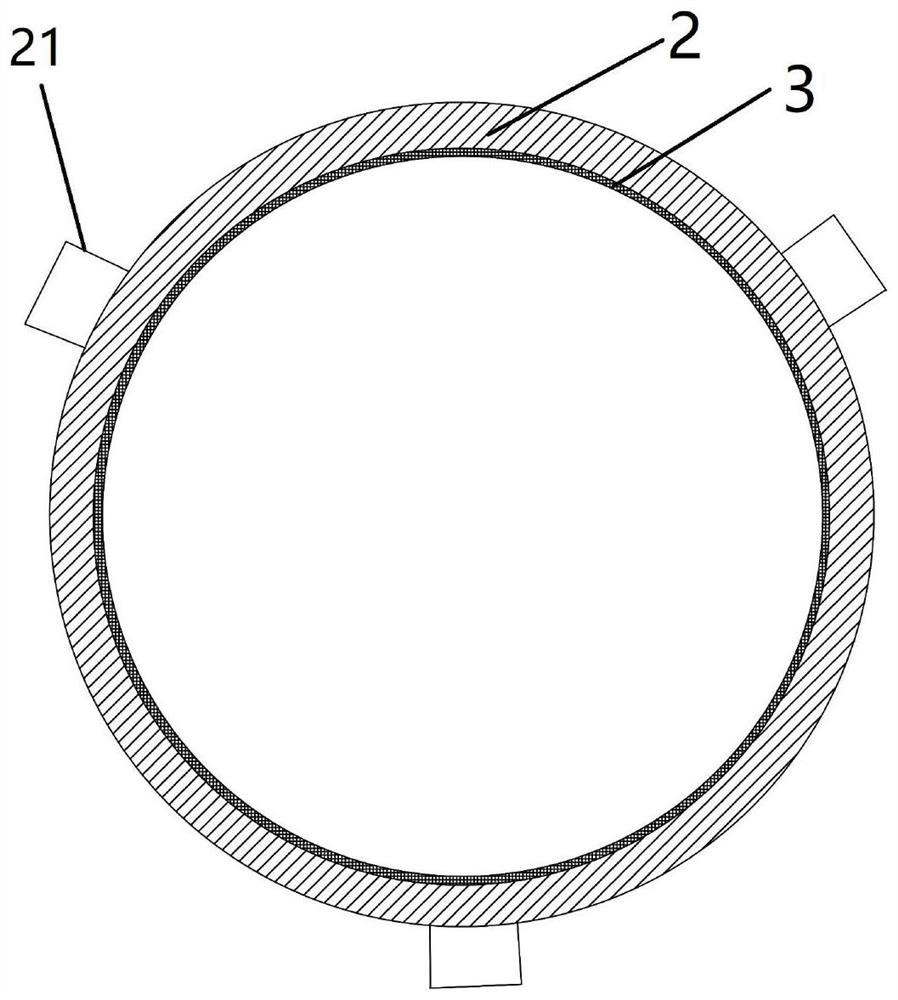

[0028] Such as figure 1 and Figure 5 As shown, the present invention provides a novel corrosion-resistant and wear-resistant cermet mud pump liner, comprising an outer liner 1, an inner liner 2 and a cermet coating 3, the outer liner 1 and the inner liner 2 are all round Cylindrical, the inner wall of the inner cylinder liner 2 is provided with a cermet coating 3 . The outer wall of the inner cylinder liner 2 is evenly provided with a plurality of limit blocks 21 along the circumferential direction, and the outer cylinder liner 1 is provided with a plurality of inverted T-shaped limit grooves 11 that match the limit blocks 21. The limit blocks 21 and Inverted T-shaped limiting slots 11 correspond one-to-one. In this embodiment, three limiting blocks 21 are arranged on the outer wall of the inner cylinder liner 2, and three inverted T-shaped limiting blocks 21 are arranged on the corresponding positions on the outer cylinder liner 1. Bit slot 11. The inverted T-shaped limit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com