Membrane and preparation method and application thereof

A film cooling and metal-organic framework technology, applied in the field of membrane separation, can solve the problems of low metal-organic framework loading, reduced specific surface area, poor separation effect, etc., and achieves excellent separation effect, easy operation and cost saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the membrane of the present invention will be described in detail below. The proportions or percentages (%) involved in the present invention refer to mass proportions or mass percentages unless otherwise specified.

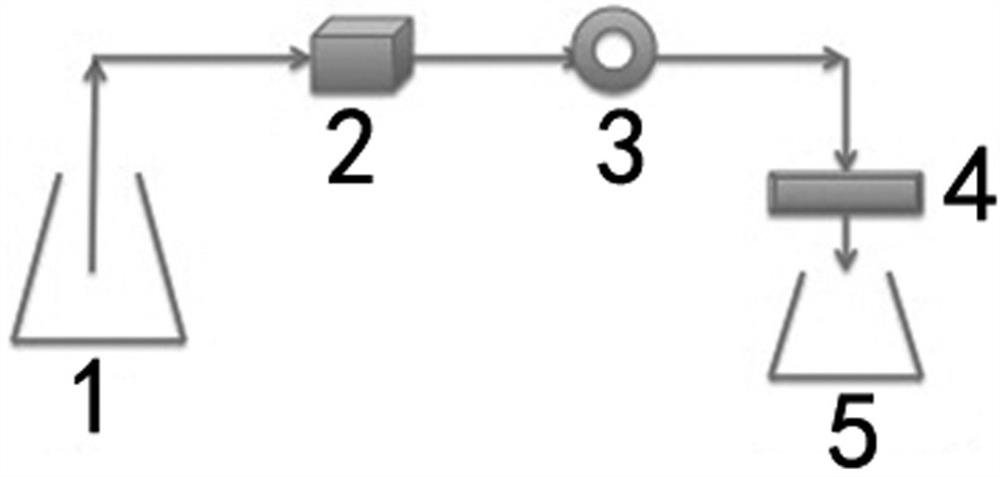

[0041] The invention discloses a new membrane preparation method, comprising:

[0042] (1) Mix the metal-organic framework material with the polymer and the pore protecting agent, melt and stir at the first temperature until the mixture is uniform, and obtain a molten mixture;

[0043] (2) Under the second temperature and the first pressure, the homogeneously mixed molten mixture is subjected to hot-pressing treatment to obtain a formed initial metal-organic framework membrane;

[0044] (3) Cool the initial metal-organic framework membrane to room temperature, soak and wash the initial metal-organic framework membrane with a pore protecting agent remover, and dry to obtain a metal-organic framework membrane.

[0045] As for the ...

Embodiment 1

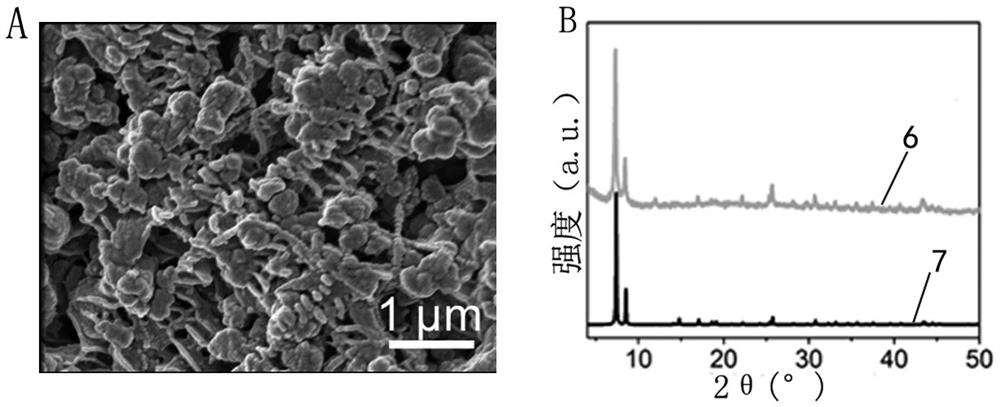

[0063] With ZrCl 4 As a metal source, 2-aminoterephthalic acid (NH 2 -BDC) for the preparation of metal-organic frameworks for organic ligands, the freshly prepared metal-organic frameworks were activated with dichloromethane. Mix 50 parts by mass of the activated metal-organic framework with 37.5 parts by mass of high-density polyethylene (Alfa aser; number: 041731) and 12.5 parts by mass of ultra-high molecular weight polyethylene (Alfa aser; number: 043951), and then Add 100 parts by mass of paraffin oil (sigma Aldrich; number: M8691). The mixture was kept stirring at 160° C. for 10 minutes. Then, at 80° C. and 0.5 MPa pressure, plate heating and pressure treatment was performed to obtain an initial film. After cooling to room temperature, the initial membrane was soaked and washed with dichloromethane repeatedly, and then dried to obtain the membrane of Example 1, in which the MOF loading was 50%. Characterization was performed using scanning electron microscopy and X-...

Embodiment 2

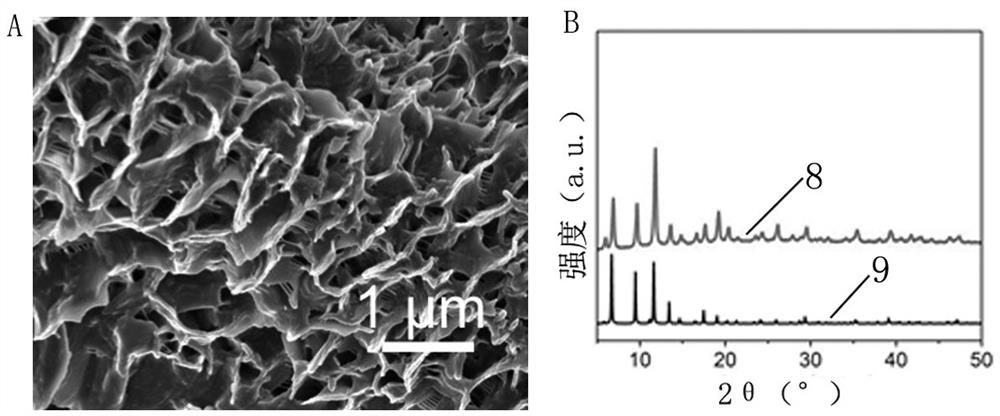

[0066] With Cu(NO 3 ) 2 As the metal source, trimesic acid is used as the organic ligand to prepare metal-organic framework materials. The freshly prepared MOFs were activated with dichloromethane. Mix 70 parts by mass of the activated metal-organic framework with a total of 30 parts by mass of ultra-high molecular weight polyethylene (Alfa aser; number: 043951) and polyvinylidene fluoride (Alfa aser; number: 044080) (ultra-high molecular weight polyethylene The mass ratio with polyvinylidene fluoride is 2:1), and then add 170 parts by mass of paraffin oil. Stirring of the mixture was continued at 200°C for 10 minutes. Then, the initial film was obtained by performing hot-pressing treatment on rollers at 120° C. and 0.8 MPa. After cooling to room temperature, the initial membrane was soaked and washed with dichloromethane repeatedly, and then dried to obtain the membrane of Example 2. The MOF loading in the obtained film was 70%. Use scanning electron microscope and X-ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com